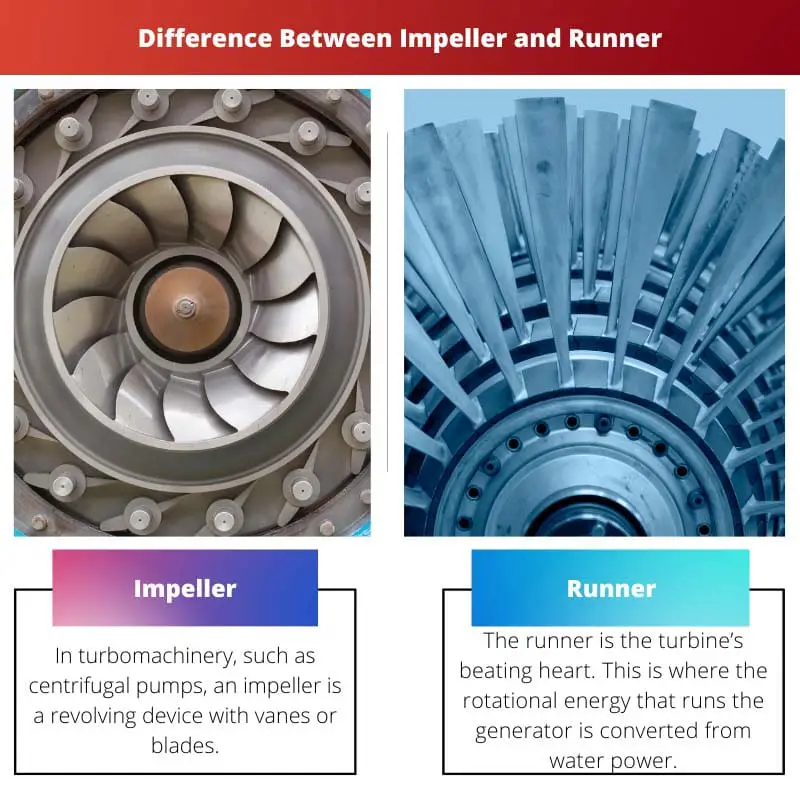

This article deals with the explanation of the difference between impeller and runner, two widely used instruments in the hydro-system industry.

Both have been invented to help in the working of water instruments. Both seem to appear the same thing but have a huge difference in their working and usage.

Key Takeaways

- Impellers and runners are rotating components in fluid-handling systems, such as pumps and turbines.

- Impellers are designed to impart kinetic energy to fluids by accelerating them, while runners extract energy from moving fluids to generate mechanical power.

- Impellers are commonly used in centrifugal pumps, whereas runners are found in turbines and hydraulic machines.

Impeller vs Runner

The impeller is a rotating component of the pump that consists of a series of curved blades or vanes that create a flow of fluid when rotated. The impeller is mounted on a shaft. The runner is a stationary component of the pump that surrounds the impeller and helps to direct the flow of fluid from the impeller to the discharge outlet of the pump.

An impeller is a propeller-like component of a pump or compressor that spins at a fast speed to raise the pressure and flow rate of a liquid.

Impellers are built of a variety of metals and polymers, including iron, steel, and bronze. As the liquid flows through the pump, the impeller transmits energy to it, increasing the liquid’s speed at the discharge end.

A runner is a component of any turbine that houses the blades. In the context of a gas turbine engine used in aerospace, it will be linked with a compressor to power it.

In the case of a steam turbine, it is used in conjunction with a generator to generate power.

Comparison Table

| Parameter of comparison | Impeller | Runner |

|---|---|---|

| Used in | Pump | Turbine |

| Material used | Cast iron | Stainless steel |

| Flow of energy | The input of mechanical energy and output of hydraulic energy. | The input of hydraulic energy and output of mechanical energy. |

| Friction losses | Relatively high. | Reduced friction losses. |

| Passage | Made of long smooth channels with gradually increasing cross-sectional area. | Runner passages are therefore relatively short. |

What is Impeller?

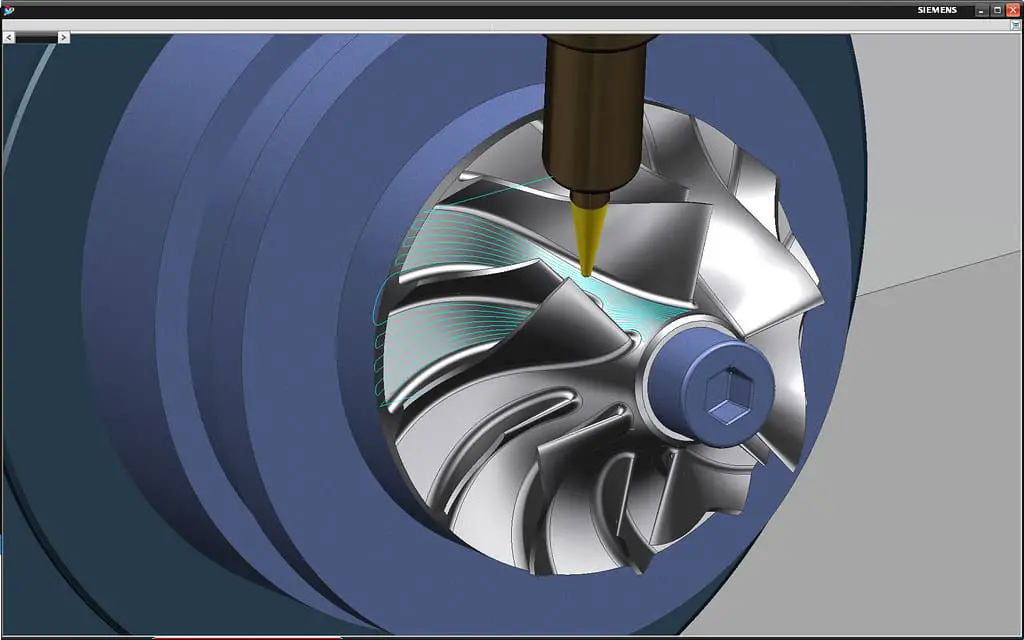

In turbomachinery, such as centrifugal pumps, an impeller is a revolving device with vanes or blades. Mechanical power is turned into pump power output through flow deflection at the impeller vanes.

The movement of a fluid-driven through a tube at a high force is enhanced by an impeller. Compressors and pumps with impellers are frequently utilized to move fluids and gases across great lengths in pipelines.

The rotational speed of an impeller is expressed in revolutions per minute (rpm). Open impellers closed impellers, and semi-open impellers are the three types of impellers.

All impellers have a rear shroud and, in the context of closed impellers, a front shroud to fit the vanes; according to the viewpoint, these can alternatively be regarded as an inner shroud and, in the instance of closed impellers, an outer shroud.

An impeller is classified as open if it has no front shroud.

The impeller must have a specified number of vanes to obtain excellent pump efficiency and low NPSHr readings. The impeller’s open, unhindered flow cross-section is increased by using a small number of vanes.

Impellers can manage somewhat contaminated liquids and solids as a result of this.

What is a Runner?

The runner is the turbine’s beating heart. This is where the rotational energy that runs the generator is converted from water power.

The buckets or blades of any runner are required for gathering as much energy as feasible from the water. The front and back curvatures of each area govern how the water will move over till it falls away.

Take into account that each runner performs best at a certain Head and Flow. The runner should be a tight match for the specifications of your site.

Choosing the proper type of steel to use while building a new turbine runner or repairing an old runner is critical.

Recognizing the qualities of different materials, especially novel stainless steel alloys, can assist project managers in drafting appropriate specifications.

To avoid air and water disturbance, seek all-metal runners with sleek, smooth surfaces. Runners that are made of one piece and finely machined operate more efficiently and securely than those that are glued together.

Tiny systems with fresh water and heads up to 500 feet benefit from bronze manganese runners. Stainless steel runners with high tensile strength are ideal for bigger systems or harsh water.

All runners should be finely balanced to reduce vibration, which not only reduces performance but also has the potential to cause harm over time.

Main Differences Between Impeller and Runner

- An impeller is an instrument used in pumps while a runner is an instrument used in turbines.

- An impeller is made of cast iron while the material used for making a runner is stainless steel.

- An impeller has an input of mechanical energy and output of hydraulic energy while for a runner it’s vice versa, i.e., input of hydraulic energy and output of mechanical energy.

- An impeller has a high frictional loss while a runner has a reduced frictional loss.

- An impeller is made of long smooth channels with gradually increasing cross-sectional area while a runner has relatively short passages.