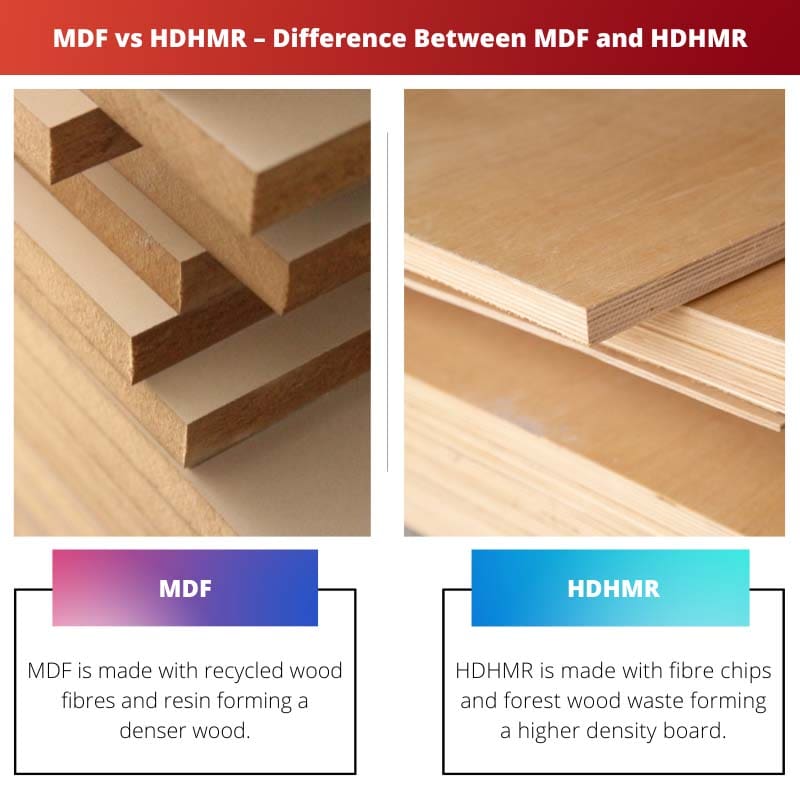

When it comes to choosing wood, we always get confused with all sorts of varieties present in the market. MDF and HDHMR are the two famous types of woods that are in demand nowadays.

The difference firstly lies in the procedure of these two. They vary in lots of different terms.

Key Takeaways

- MDF (Medium Density Fiberboard) is a wood composite made from wood fibers and resin, while HDHMR (High-Density, High Moisture Resistant) is a type of MDF with increased moisture resistance.

- HDHMR is more durable and water-resistant than standard MDF, making it suitable for humid environments and heavy-duty applications.

- MDF is cheaper and easier to work with, while HDHMR is a more specialized material for specific uses.

MDF vs HDHMR

MDF is a wood product made by breaking down hardwood or softwood residuals into wood fibres and combining it with wax and resin binder under high temperature and pressure. HDHMR is a variant of MDF that has a higher density and moisture resistance. It is used in high-humidity areas.

MDF stands for “medium density fireboard”. It is a stunning piece for the interior decor of your house, office or any other place. It is also handy in making furniture because of its smoothness.

These do not have any knots. MDF is not much durable and cannot hold weight more than 50-60kgs.

HDHMR stands for “high-density high moisture resistance”. As the name suggests, it shows excellent results in being highly resistant to water.

It is more sturdy than plywood. It offers substantial strength. It is a hardwood made up of eucalyptus wood. It also comes with a multidimensional bond with exclusive lustre.

Comparison Table

| Parameters of Comparison | MDF | HDHMR |

|---|---|---|

| Definition | MDF is made with recycled wood fibres and resin forming a denser wood. | HDHMR is made with fibre chips and forest wood waste forming a higher density board. |

| Full form | MDF stands for medium stand fireboard. | HDHMR stands for high density high moisture resistance. |

| Usage | MDF is used to make furniture, cabinetry, fire resistance, vapour repulsion, roofing and soundproofing. | HDHMR is used to make wardrobes, door shutters, partitions, panelling, kitchen interiors, desks and lockers. |

| Cost | MDF is inexpensive. | HDHMR is quite expensive. |

| Moisture resistance | MDF does not have a water holding capacity. | HDHDMR have a great water holding capacity. |

What is MDF?

MDF is known for its smooth surface and shiny appearance. However, it is not much strong in contrary to other hardwoods but is very durable.

It is an engineered wood made by residuals of hard and softwoods affixing with wax and resins. MDF is the most malleable wood.

It is very compact. It is non-bendable and hence is not easy to crack. One more thing that made MDF a better choice is its price, which is very affordable.

MDF is knot-free. It does not expand on heating and also does not contract. MDF aids in environmentally free substances as it has a recycling production.

It does not possess grain which gives the advantage of cutting it simply far apart from other natural woods. It absorbs water doubtlessly and shows swelling. On application of veneer gives the appearance of solid wood.

There are various types present among MDF. Like ultralight MDF plate, moisture resistant board, fire retardant MDF are some of its types.

It gives a uniform density. It is also resistant to some insects because of a few chemicals engaged while making it. It is approachable for depiction.

Its uses are making furniture, doors, cabinets, partitions. It is briefly in use in almost every house and office due to its minimum price range.

What is HDHMR?

HDHMR is one of the well-built wood about decors both inside and outside. It is versatile and is perfect for indoor as well as outdoor constructions.

It is more resilient than other woods, especially plywood. So it can facilely replace plywoods. The maintenance is also not much hectic. Being pricey, it fills all the requirements that we yearn for nowadays.

There are copious amounts of benefits and advantages in an HDHMR fibreboard. Firstly, its water-resistance quality is the centre of this product.

This exceedingly quality has increased the demands and the marketing. It also has a resistance to borer infestations. It is fungal resistant as well, making it much safer.

It is a termite-free product that by any means cannot cause harm. It also defuses any attractant that could get in contact with these insects.

Their maintenance is low. Because of its high resistivity to moisture, wiping with wet cloths can remove the dust. This property makes it perfect for damp areas like kitchen, bathrooms, etc.

It is a ponderous material. Its superior quality is the thing that makes it the first and foremost choice for everyone. HDHMR marks an alternative for most of the woods opting, it is more approachable.

Main Differences Between MDF and HDHMR

- MDF tends to be lesser dense than HDHMR because HDHMR provides high density.

- MDF does not come with pre-polish, on the contrary, HDHMR already comes with polis with smooth finishing.

- MDF does absorb moisture and can swell in contact with water but HDHMR does not absorb moisture at all.

- MDFs are not safe as in the processing of this fibreboard urea formaldehyde is used. On the other hand, HDHMR is safer than this.

- MDF does not hold screws and nails efficiently, whereas HDHMR takes up the screws and nails.

- MDF can break or crack in extreme stress. On the other hand, HDHMR can hold heavier things easily.