Are you looking for a plywood or wood substitute? MDF and particleboard are two of the greatest options when you need a replacement for the real deal.

Engineered wood includes MDF (Medium-Density Fiberboard) and particleboard. Wood by-products such as fibres, sawdust, and shavings are used to create these “woods.”

These components are mixed with chemicals and glue before being compacted into a substance of various thicknesses.

Key Takeaways

- MDF provides a smoother surface and better edge-shaping capabilities than particleboard.

- Particleboard costs less and offers environmental resistance compared to MDF.

- MDF has a higher density, while particleboard has a more diverse composition, including wood chips and sawdust.

MDF vs Particleboard

MDF (Medium Density Fiberboard) is formed by glueing together wood fibres under high pressure and heat, resulting in a smooth and uniform surface. Particle board is composed of wood particles bonded with resin resulting in a rougher texture and lower density.

MDF is said to be the better of the two materials. Engineered wood is made up of small wood fibres that are invisible to the naked eye. It has a smooth texture and a veneer that makes it look like natural wood.

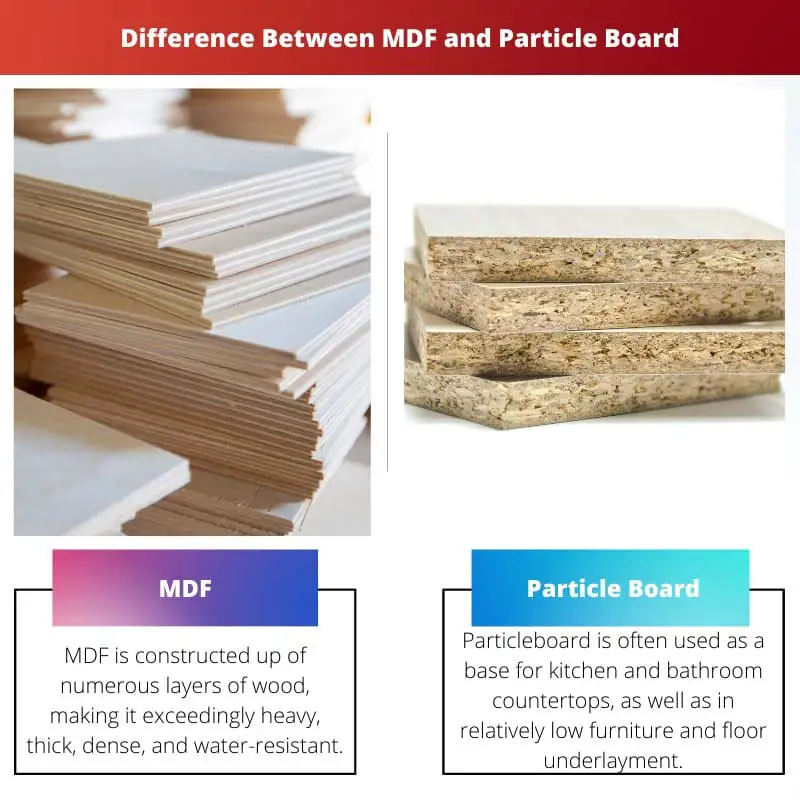

MDF is constructed up of numerous layers of wood, making it exceedingly heavy, thick, dense, and water-resistant. This wood is also more durable and resistant to cracks and splits.

Particleboard is used as a base for kitchen and bathroom countertops and in relatively low furniture and floor underlayment.

All power tools can be used to mill the material, but it has a substantial amount of tear-out. A thin coating of lamination or veneer is frequently applied to the surface to improve the look of the particleboard.

Because it tends to chip and break, particleboard is difficult to mould or shape.

Comparison Table

| Parameters of Comparison | MDF | Particleboard |

|---|---|---|

| Looks | Smooth finish. | Doesn’t have a smooth finish. |

| Density | Has a higher density. | Doesn’t have a high density. |

| Strength | MDF is stronger than particleboard. | The particleboard is not much strong. |

| Water Resistance | More resistance to water. | Less resistance to water. |

| Pricing | MDF is expensive | Particleboard is cheap. |

What is MDF?

MDF stands for medium-density fiberboard, which is an effectively artificial construct made from hardwood & softwood composites that have been broken down.

There have been no apparent wood grains or knots on an MDF board because it is made up of microscopic wood fibres.

The fibres are bonded together with wax by exerting pressure on hot temperatures to create panels. Now that you know what such an MDF board is made of, you’re probably curious as to how good or horrible it is.

When compared to wood, MDF is less expensive. MDF boards have a very flat surface that makes them ideal for decorating.

MDF is good for cutting & carve designs because of its smooth edges. It has a higher density and strength than particleboard. MDF gives a natural and royal look and is worth the price.

MDF, like any other substance, has its own set of drawbacks: MDF absorbs water as well as other liquids like a cushion and expands if not properly sealed.

MDF is incredibly heavy and tough to work with because it is a solid substance. It doesn’t grip screws so well because it’s constructed of fine fibre. If not handled carefully, MDF is quickly damaged and sags.

What is Particleboard?

Another low-cost product derived from leftover wood materials is particle-board. It’s manufactured by pressing resin and sawdust together along with heat.

Particleboards are frequently utilized in the production of low-cost home decorating furniture. It can also be used as a foundation layer for countertops.

Particleboard is easy to drill into but has a certain amount of tear-out. A particle board’s surface is finished with laminate or veneer to improve its appearance.

Particleboard is hard to shape and mould because it tends to crack or chip.

Particleboard has several advantages over other products such as MDF, solid wood, and plywood, one of which is its inexpensive cost. It’s small and light, making it simple to carry and travel.

When compared to MDF, it has a superior power to retain nails & screws. It is simple to manage and sanitize. It’s simple to drill, cut, grind, paint, glue, and so on.

It’s a green product created from waste wood materials, including sawdust, wood chips, and shavings.

Compared to other house interior materials like plywood and MDF, particle boards are not as sturdy. Because of its poor strength, it should be treated with caution because it is easily damaged.

Particleboards have a short lifespan. It has poor resistance to dampness and wetness. One of the major drawbacks of particle boards is this. Particleboards can expand when exposed to moisture.

Particleboards are not environmentally friendly since some types of particleboards are made with a resin that can be damaging to one’s health.

Main Differences Between MDF and Particleboard

- Regarding aesthetics, usage, strength, moisture, and water exposure, MDF is a considerably superior engineered wood to particleboard.

- In comparison to particleboard, MDF is heavier, thicker, and more durable, with a lower risk of breaking or splintering.

- MDF is not so budget-friendly in comparison to Particleboard.

- Because of its look and resilience to paint and finishes, particleboard is frequently utilized for interior applications. MDF, on the other hand, has a lovely, smooth finish, as well as a good reactivity to paint and finishes and an almost wood-like look.

- MDF is more adaptable than particleboard, which can be used for shelves, decorative moulding, flooring, and standalone furniture such as doors and cabinets. It can also withstand a lot of stress and has a lot of strength. Particleboard doesn’t hold up well under stress and is not suitable for all tasks.

This does not cover anything new, I was expecting more in-depth analysis

It’s great to read the comprehensive explanations of MDF and Particleboard. It really helps in understanding the differences.

The article is highly educational and informative.

I found it quite engaging, and the content was quite enlightening.

I already knew this information, but it’s a good read for someone who is not familiar with it.

The article presents a very objective comparison between the two materials.

The content is very well researched and provides a balanced view of MDF and Particleboard.

Well, I was not impressed at all. It was a lot of information and nothing new.

The details about the comparison table is extremely useful.

Indeed, having a comparative analysis of MDF and Particleboard is quite enlightening.

This is very good information about MDF and Particleboard. It’s great to have a detailed comparison of the two.

The article provides a clear and concise explanation of these materials

I agree, it is very informative and helpful