Rafters are traditional structural components, individually cut and installed to support a roof’s weight, offering versatility in design but requiring more labor for installation. Trusses are prefabricated frameworks made of interconnected members, offering cost efficiency and faster installation but limiting design flexibility compared to rafters.

Key Takeaways

- Rafters are sloping beams that support a roof’s weight and transfer it to the walls, creating a traditional and flexible roofing system.

- Trusses are prefabricated structural units with interconnected triangles and offer a more efficient and cost-effective roofing system.

- Rafters and trusses differ in their construction methods, aesthetic appeal, and load-bearing capacities.

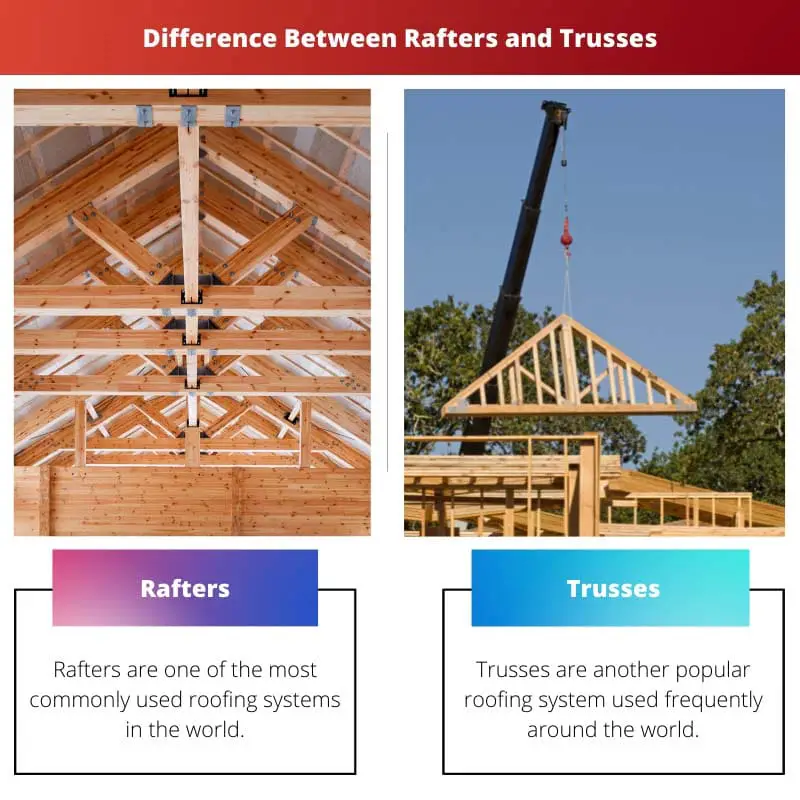

Rafters vs Trusses

Rafters are sloping structural members that extend from the peak of the roof down to the eaves. Trusses are pre-fabricated structural components made of wood or steel. They consist of a series of interconnected triangles forming a rigid framework, which is lifted and attached to the top of the walls.

The truss framework comprises multiple triangularly webbed panes, which boost the framework’s strength to offer enhanced support to the rooftop. Alternatively, rafters are made with sloping outer beams that offer reduced support to the rooftop.

Comparison Table

| Feature | Rafters | Trusses |

|---|---|---|

| Type | Individual beams | Pre-fabricated assemblies |

| Construction | Built on-site, from dimensional lumber (2x8s, 2x10s, 2x12s) | Manufactured in factories, using smaller lumber (2x4s) |

| Strength | Can handle moderate loads | Can handle larger spans and heavier loads due to triangular design |

| Span | Limited to about 30 feet | Can span up to 60 feet or more |

| Customization | Easier to customize for unique roof shapes | Limited customization options |

| Installation | Requires more time and skilled labor to cut, assemble, and install | Faster and easier to install due to pre-fab nature |

| Cost (Material & Labor) | Generally more expensive due to on-site construction and potentially needing additional support beams | Can be more cost-effective due to less on-site labor and potentially needing less lumber overall |

| Insulation | Insulation placed between rafters in a finished space or between joists above in an unfinished attic | Can have pre-drilled holes for easier insulation placement within the truss itself |

| Design Flexibility | More flexibility for vaulted ceilings or cathedral designs | Limited to simpler roof designs |

What are Rafters?

Rafters are essential components of traditional roof construction, providing structural support and stability. They are inclined beams that extend from the ridge of the roof down to the eaves, forming the framework upon which the roof covering is laid. Rafters bear the weight of the roof and transfer it downward to the walls or other supporting structures.

Characteristics

- Individual Construction: Rafters are individually cut on-site according to the specific dimensions and angles required for the roof design. This customization allows for flexibility in accommodating various roof shapes, pitches, and architectural styles.

- Material Variability: Rafters are commonly made of wood, although other materials such as steel or engineered lumber may also be used. Wood rafters are chosen for their strength-to-weight ratio, affordability, and ease of handling during construction.

- Installation Process: Installing rafters involves precise measurement, cutting, and placement. Each rafter must be accurately positioned and secured to ensure the structural integrity of the roof. This process can be labor-intensive and time-consuming, especially for complex roof designs.

- Versatility: Rafters offer flexibility in roof design, allowing for the incorporation of features such as dormers, valleys, and skylights. Their individual construction enables adjustments to accommodate architectural preferences and site-specific requirements.

Advantages and Disadvantages

- Advantages:

- Versatile design options.

- Suitable for custom or unique roof shapes.

- Potential for intricate architectural features.

- Disadvantages:

- Labor-intensive installation process.

- Greater time and effort required for customization.

- Limited span capabilities compared to trusses.

What are Trusses?

Trusses are prefabricated structural frameworks composed of interconnected members, designed to support the roof’s weight and transfer it to the building’s walls or supports. These assemblies are engineered to distribute loads efficiently, offering strength and stability while minimizing material usage. Trusses are commonly used in residential, commercial, and industrial construction projects.

Characteristics

- Prefabricated Construction: Trusses are manufactured off-site according to precise engineering specifications. They are fabricated in controlled environments using computer-aided design (CAD) and manufacturing (CAM) technology, ensuring consistency and accuracy in construction.

- Interconnected Members: Trusses consist of triangular configurations of beams, chords, and web members. This geometric arrangement maximizes structural integrity and load-bearing capacity while minimizing material requirements. The triangular shape distributes forces evenly throughout the truss, enhancing stability.

- Standardization: Trusses are available in a variety of standard designs and configurations to accommodate different roof spans, pitches, and load requirements. Common types include king post, queen post, and Howe trusses, each tailored to specific structural needs and architectural preferences.

- Efficient Installation: Installing trusses involves lifting and positioning the prefabricated assemblies onto the building’s walls or supports. Once in place, trusses are secured and connected using fasteners or hardware. Compared to rafters, trusses offer faster installation times and reduced labor costs, contributing to overall construction efficiency.

Advantages and Disadvantages

- Advantages:

- Rapid installation due to prefabrication.

- Consistent quality and structural performance.

- Cost-effective material usage.

- Ideal for large spans and repetitive designs.

- Disadvantages:

- Limited design flexibility compared to rafters.

- May require specialized equipment for handling and installation.

- Difficult to modify or customize on-site.

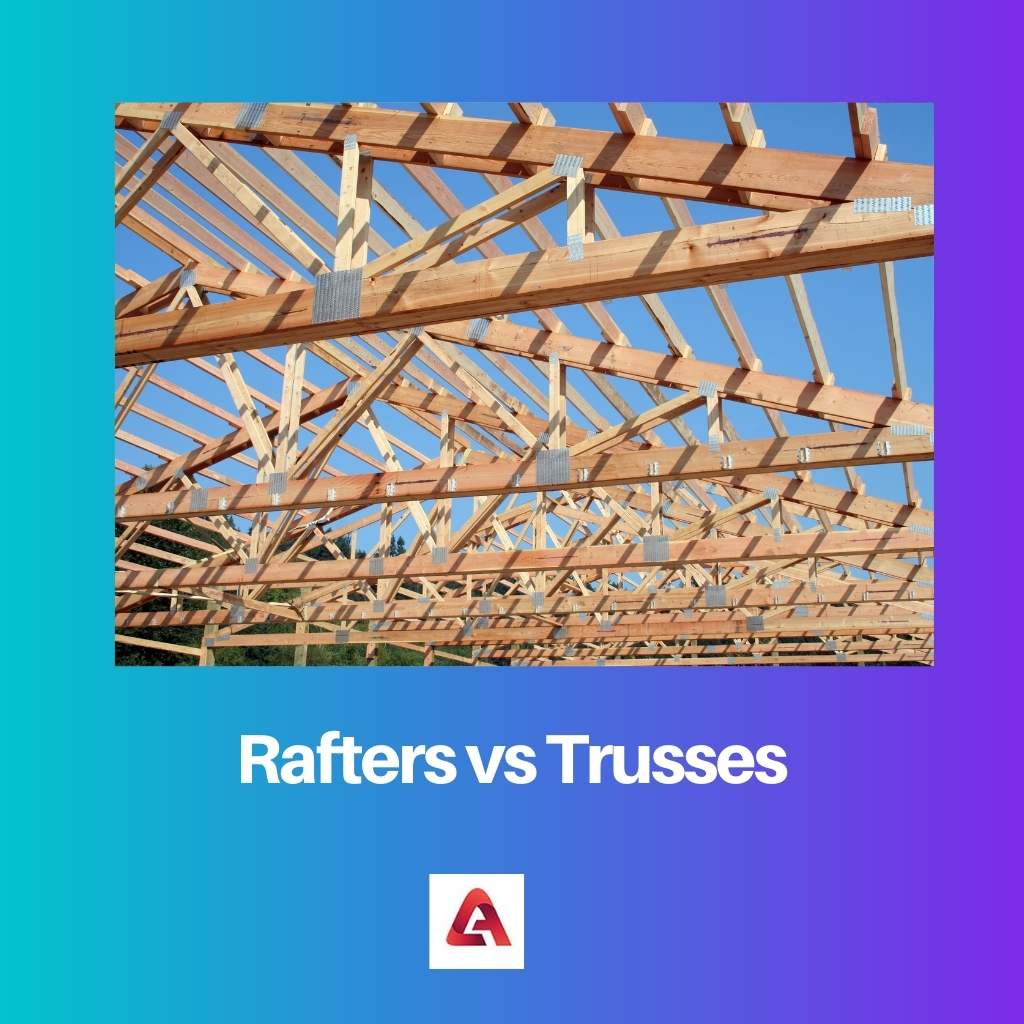

Main Differences Between Rafters and Trusses

- Construction Method:

- Rafters are individually cut and installed on-site, allowing for customization to accommodate various roof shapes and designs.

- Trusses are prefabricated off-site according to standardized designs and engineered specifications, offering efficiency in installation but limited customization options.

- Structural Design:

- Rafters rely on individual beams to support the roof’s weight, providing versatility in design but potentially requiring more labor-intensive installation.

- Trusses are composed of interconnected members forming triangular configurations, maximizing structural integrity and load-bearing capacity while minimizing material usage.

- Installation Process:

- Rafters require precise measurement, cutting, and placement during installation, which can be time-consuming and labor-intensive, especially for complex roof designs.

- Trusses offer rapid installation due to their prefabricated nature, with assemblies lifted and positioned onto the building’s walls or supports, reducing labor costs and construction time.

- Flexibility vs. Efficiency:

- Rafters offer greater flexibility in accommodating architectural preferences and site-specific requirements, making them suitable for custom or unique roof shapes.

- Trusses prioritize efficiency and consistency in construction, making them ideal for projects with repetitive design elements or large roof spans where rapid installation is crucial.