While passing by construction sites, it is quite noticeable for everyone to see large machines involved in digging the earth and moving sand, gravel, and other substances from one place to another. The two of the most common machines used in these sites are bulldozers and wheel loaders. They might look the same but are different from many perspectives.

Key Takeaways

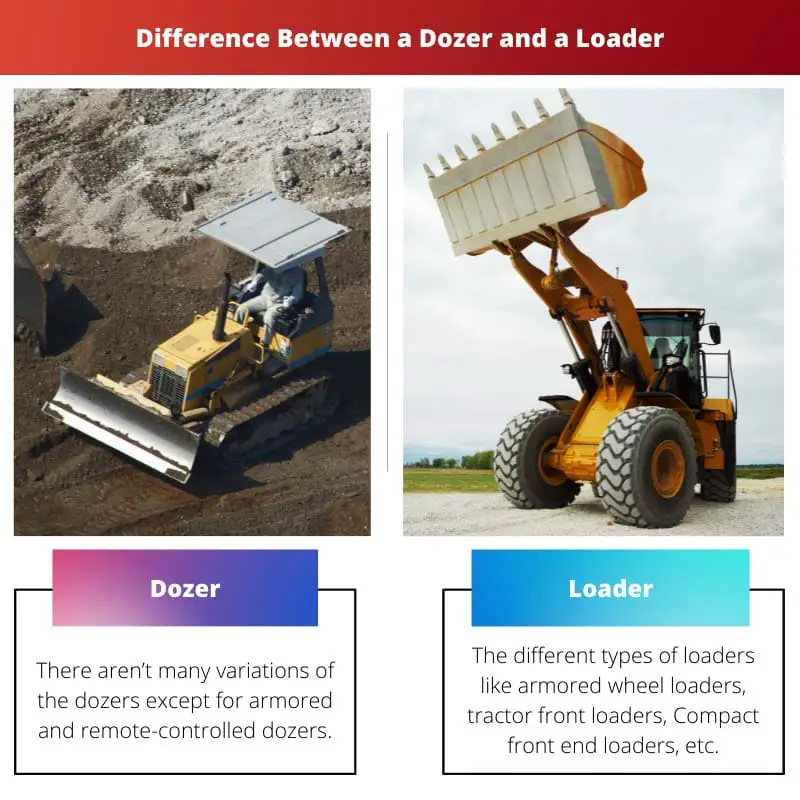

- Dozers have a large blade for pushing and levelling materials, while loaders have a bucket for scooping, lifting, and moving materials.

- Dozers excel in tasks requiring heavy earthmoving or grading, whereas loaders are more versatile for loading trucks or transporting materials on-site.

- Both dozers and loaders are essential pieces of heavy equipment in construction, but each serves a distinct purpose and function on a job site.

Dozer vs Loader

The difference between dozers and loaders is that dozers are used for flattening the earth with soil or sand, while loaders are mainly used for shovelling the ground and carrying loads from one place to another. Apart from these, the loaders can carry out materials on conveyer belts and articulated dump trucks.

The dozers are heavy and tracked equipment used for flattening the earth. The tracks present in them provide the machines with a sterling ground-holding capacity, that is, the ability to make contact with the ground. The dozers’ tracks provide mobility and help them distribute the machine’s heavyweight. This prevents the machine from sinking/drowning even while working in mud.

Wheel loaders are specific kinds of tractors designed to shovel the ground and carry large amounts of soil, mud, gravel, or any material to another place without dropping them on the ground. They have a bucket-like structure fitted in the front, allowing the machines to carry heavy loads without problems.

Comparison Table

| Parameters of Comparison | Dozer | Loader |

|---|---|---|

| Types | There aren’t many variations of the dozers except for armored and remote-controlled dozers. | The different types of loaders like armored wheel loaders, tractor front loaders, Compact front end loaders, etc. |

| Components | Blades(S-type, U-type, S-U-type) and the ripper | Axles, hydraulic pumps, motors, valves, sweeper, forks, etc. |

| Major Manufacturing Companies | Caterpillar. Komatsu, Liebherr, Case, and John Deere | LiuGong, JCB, TATA |

| Usage in the Army | Used to protect the drivers from firearms and debris in combat zones | Construction and combat engineering roles, also used for demolishing small houses |

| Support for Movement | Since they are tracks in the bottom, they need to be transported from one place to other with the help of some other vehicles, when it comes to movement on roads. | When it comes to movement on roads, they can easily move from one place to another as they have wheels in the bottom. This also allows them to carry heavy loads to conveyor belts and articulated dump trucks. |

What is a Dozer?

The dozers are the best machines when it comes to clearing the ground and levelling it. The machines are designed systematically to take advantage of the track system and be close to the ground. Being close to the ground allows the tracks of the dozer to function appropriately.

For a long time, bulldozers have been in use in farms and industries for construction and loading-unloading purposes. The first dozer was made from Holt farm tractors which were used in ploughing farms. The machines were used for the contribution of the armoured tanks in World War I.

The dozers have two primary tools, namely the blade and the ripper. The blades are of three types. The S-type blade is and helps in fine grading. The U-type blade is quite large and is useful in carrying more materials. The S-U type blade is shorter and helps in pushing or moving heavier rocks.

The ripper is the long claw-line structure at the back of the dozer. As the name suggests, the ripper is used to cut or rip the soil so that the soil loosens. The loosening of the soil makes it easy for the machines to dig the earth and then carry the soil.

What is a Loader?

A loader is a specialized tractor that has a large bucket in front of it. The bucket is connected to the loader’s two arms, making it easy for the machine to carry any load from the ground.

The world’s first loader was a backhoe loader developed by the JCB Company in the USA in 1935. Even at that time when the technology was not as developed as now, the company designed the machine to keep the backhoe and the loader intact. The backhoe was used to dig the ground, and then it rotated to the front to transfer the dug soil into the bucket.

The first wheel loader was invented by Volvo Construction Equipment in 1954. At that time, these were based on the model of a tractor and a rear-wheel drive. Today, wheel loaders are used by several defence forces like Israel, Turkey, and the Netherlands.

The primary job of the loader is to shovel the earth and carry the loose material from the ground, such as sand, snow, debris, etc. The major parts of the loader are the engine, hydraulic components like pumps, valves, and motors, and some transmission components like wheels, axles, etc.

Main Differences Between a Dozer and a Loader

- Dozers are used for flattening or clearing the earth, while loaders are used for digging the earth and carrying the materials.

- Dozers have two main parts, namely the blade and the ripper, while loaders have hydraulic components like pumps, valves, motors, etc.

- Dozers have tracks at the bottom to level the ground, while loaders have wheels to carry the materials from one place to another.

- The front blades of the dozers can be changed according to the use, while the bucket is not changed because it is used for carrying loads.

- The dozers are mostly used at mining sites, farms, military bases, etc., whereas loaders are used mostly at construction and industrial sites.