Ladders are used to reach higher grounds for cleaning, repairing, or storage. Thus, while making a ladder, the manufacturer has to calculate the weights that the ladder would be subjected to.

Along with making a sturdy frame, the ladder should be light enough to carry and store easily.

Key Takeaways

- Aluminum ladders are lightweight, affordable, and corrosion-resistant, making them suitable for various indoor and outdoor tasks.

- Fiberglass ladders are non-conductive, sturdy, and durable, ideal for working near electrical sources.

- The choice between aluminum and fiberglass ladders depends on the intended use, required durability, and safety considerations.

Aluminum Ladders vs Fiberglass Ladders

Aluminium ladders are ladders made of aluminium, a lightweight and durable metal, and are popular due to their durability, corrosion resistance, and ease of handling. Fibreglass ladders are ladders made of fibreglass, a composite material made from glass fibres and resin, ideal for electrical work.

Aluminum is a metal known for its high tensile strength, lightweight, and resistance to environmental corrosion. This is the reason why Aluminum is used in many high-performance applications, such as the manufacturing of race cars and aeroplanes.

Thus naturally, Aluminum ladders are also very strong and can good amounts of weight without getting damaged.

Fibreglass is a composite material made of glass fibres and a binding resin. It is known for its rigidity, strength, and resistance to environmental conditions.

Thus Fiberglass does not get affected by changes in environmental conditions. As a result, ladders made of Fiberglass are very durable.

Comparison Table

| Parameters of Comparison | Aluminum Ladders | Fiberglass Ladders |

|---|---|---|

| Tensile Strength | Aluminum ladders have more tensile strength | Fiberglass ladders have less tensile strength |

| Rigidity | Aluminum ladders have less rigidity | Fiberglass ladders have more rigidity than aluminum ladders |

| Weight | Aluminum ladders are comparatively lighter | Fiberglass ladders are heavier for the same length as aluminum ladders |

| Portability | As aluminum ladders are light, they are more portable | Due to heavier weight, fiberglass ladders are not as portable |

| Cost | Aluminum is cheaper than fiberglass and hence aluminum ladders are also cheaper | Fiberglass ladders are slightly expensive than aluminum ladders |

What is an Aluminum ladder?

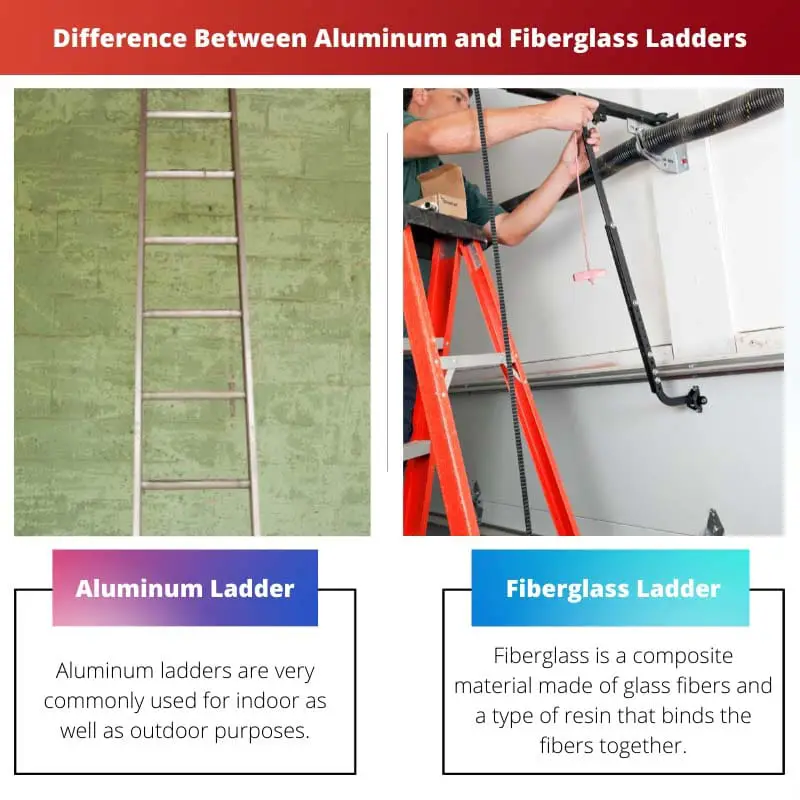

Aluminium ladders are very commonly used for indoor as well as outdoor purposes. These ladders offer more versatility and usability than wooden ladders or ladders made of other composite materials.

Aluminium is a lightweight metal known for its high tensile strength and corrosion to most environmental conditions. As a result, the ladders made of aluminium are also lighter than other types of ladders and can carry more weight.

As aluminium is very tensile, it does not break easily. Rather the metal bends when subjected to weight. Thus aluminium ladders do not crack easily.

Along with being more tensile, aluminium ladders are also lighter than other types of ladders for the same height and frame size. Thus these ladders can be easily carried and stored, increasing their portability.

The only drawback of Aluminum ladders is that they can quickly get hot when placed in the sunlight. Aluminium is also a good conductor of electricity, and thus it can complete a stray circuit placed in the path of electricity.

Thus caution must be maintained when using an Aluminum ladder for performing outdoor repair work, such as electrical repair, as it can lead to electrocution if the ladder comes in contact with stray charges.

What is Fiberglass Ladder?

Fibreglass is a composite material made of glass fibres and a type of resin that binds the fibres together. The resulting material is very tough and has high rigidity. Fiberglass has many applications, including the manufacturing of sports car bodies.

Thus the ladders made of Fiberglass are also very rigid and tough. Thus they can withstand heavy loads being applied to them without taking any damage.

Fibreglass is also completely resistant to environmental conditions such as rainwater and moisture in the air. Thus, there is no chance of rusting or decaying material in fibreglass ladders.

The only drawback with fibreglass ladders is that they are heavier than Aluminum and other types of ladders. This hinders the portability of Fiberglass ladders.

Along with being heavy, they are also less tensile. Thus Fiberglass ladders do not bend under weight and crack under heavy loads.

Thus while using Fiberglass ladders, the load limit that the ladder can support must be noted, if the load is more than the limit, the ladder might crack and break.

Fibreglass is also more expensive than Aluminum. Thus fibreglass ladders of the same height and similar frame structure cost more than their Aluminum counterparts.

Main Differences Between Aluminum and Fiberglass Ladders

- Aluminium ladders have more tensile strength than ladders made of Fiberglass.

- Fibreglass ladders have more rigidity than aluminium ladders

- Aluminium ladders are very lightweight. Fibreglass ladders are comparatively heavier than aluminium ladders

- As Aluminum ladders are light, they are also easy to carry and hence are very portable. Fibreglass ladders being heavy, are tough to carry around and hence are not as portable.

- Aluminium is cheaper than Fiberglass, and hence ladders made of Aluminum cost less than ladders made of fibreglass