L-pipe is used to transport gas and liquid. M-pipe has a larger interior diameter than L pipe, which makes it perfect for transporting large quantities of fluids when compared with smaller pipes like L or DWV piping systems.

While both pipes can be made from the same material (copper), L-pipe is much more rigid and cannot be bent or cut to size.

Key Takeaways

- L copper pipes have thicker walls, providing greater durability and a longer lifespan than M copper pipes.

- M copper pipes are more affordable due to their thinner walls, making them suitable for budget-conscious projects.

- L copper pipes are ideal for underground and outdoor use, while M copper pipes are commonly used for indoor water distribution.

L Copper Pipe vs M Copper Pipe

L copper pipes are the most common type of copper pipe used in residential and commercial plumbing applications. They are made from high-quality copper and have a wall thickness. M copper pipes are similar to L copper pipes in terms of their composition and manufacturing process. However, they have a slightly thinner wall thickness, which makes them more affordable than L copper pipes.

L-pipe features an inside diameter between 36mm and 76mm. L-pipe is used to transport gas and liquid. L-pipe is used in residential applications because it’s easier for plumbers and homeowners to install and connect.

L-pipes can also be installed above the ground or below grade.

While M-pipe is made from a flexible metal called “copper” and can bend slightly, which means it’s perfect for transporting large quantities of fluids (like water).

M-pipes are available in a range of sizes from 25mm to 900mm.”M pipes require a vaulted installation that provides support from beneath (up inside of a concrete wall).

Comparison Table

| Parameters of Comparison | L Copper Pipe | M Copper Pipe |

|---|---|---|

| Fittings | L size pipe is thicker. | M pipes will offer a tighter fit. |

| Length | The length of the L copper pipe is smaller. | The length of an M copper pipe is longer. |

| Inside Diameter | L pipe is comparatively thin. | The thickness of M pipes is thicker. |

| Benefits | This type of piping has a thinner wall. | This type of piping has a thicker wall. |

| Length of Pipe | The maximum amount for an L copper pipe would be calculated by multiplying 12 inches (0.3048 meters) with its corresponding gauge. | M pipes which are limited to a max amount of 240 feet (73.1592 meters). |

What is L Copper Pipe?

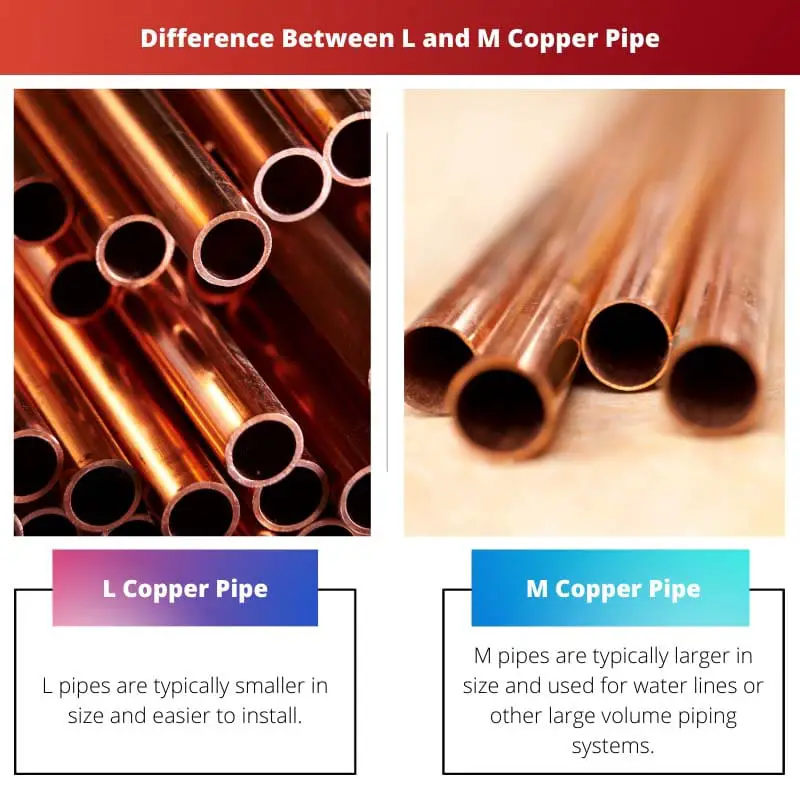

L pipes are smaller in size and easier to install. L-pipe is used for gas, water or other fluids in residential applications because it’s easier for plumbers and homeowners to install and connect.

L-pipes can also be installed above the ground or below grade.”

L-pipes are used in residential applications because they’re easier to install and connect. L-pipe can be installed above the ground or below grade.

L-pipes can be installed quickly and are easier to connect. L-pipe is also used in residential applications because they’re easy for plumbers or homeowners to install and connect.

L-pipes can be difficult to work with within tight spaces. In some applications, they may not fit into a confined space or bend at angles other than 90 degrees.

L-pipe is larger and heavier than other types of pipe, which makes them harder for plumbers to carry and install.

They’re used as a solution when L pipe isn’t feasible because they’re small and lightweight. L pipes offer a variety of benefits to homeowners, plumbers, and plumbing contractors alike.

They’re easier to install than L pipes because they can fit in tight spaces with ease.

What is M Copper Pipe?

M pipes are larger in size and used for water lines or other large-volume piping systems. The larger sized pipe can be installed below grade because of their weight and strength.

M pipes are also easy for homeowners or professional plumbers to work on because they weigh less than the other types of piping.”

M pipes are easier to work with because they weigh less than the other types of piping.

It is also easy for homeowners or professional plumbers to install M pipes in tight spaces, which makes them more versatile and easier to use than L copper pipe.”

Some people don’t like working with M copper pipes because they are not as rigid. Another disadvantage that can be a problem for some people is the weight of them, which makes it more difficult to install larger sizes below grade.

“M copper pipe is used mostly for draining, heating and air conditioning. They are also very versatile because they can be installed in tight spaces.”

Main Differences Between L and M Copper Pipe

- The size of L and M copper pipes is different: the inside diameter, outside diameter, and weight. L pipe weighs about 80 pounds per foot, whereas the M pipes weigh only 68 pounds per foot.

- L pipe ductile iron pipes are made with a seamless process that produces a pipe with no seam. M pipes are made by a continuous casting process, which produces seams on the inside and outside of the pipe.

- L copper tube has an additional benefit: it is classified as Type K for use in high-pressure applications where higher pressures can be expected to exist. M Copper Pipe does not have these benefits because it is not classified as Type K.

- M Copper Pipe has one advantage over L pipe, though: M pipes are easier to handle and can be installed with a smaller inside diameter, which may make them more cost-effective in some cases.

- L Copper Pipe: Type L has more material and can withstand higher pressures better than M copper tube. However, because it is heavier than M pipe and requires larger holes for installation, the cost may dictate whether this type is the best option.