Every machine has moving elements that move relative to one another in a sliding or rolling action. Linear sliding motion, such as in machine tools, and rotation motion, such as in motor vehicle wheels, are examples of relative motion.

Bearings are precision-machined components that allow machines to operate at extremely high speeds, decreasing friction and handling stress between moving elements.

Key Takeaways

- Bearings are a machine element that reduces friction between moving parts, while bushings provide support and reduce friction between stationary parts.

- Bearings can rotate around an axis, while bushings cannot.

- Bearings are used in high-speed and high-load applications, while bushings are used in low-speed and low-load applications.

Bearing vs Bushing

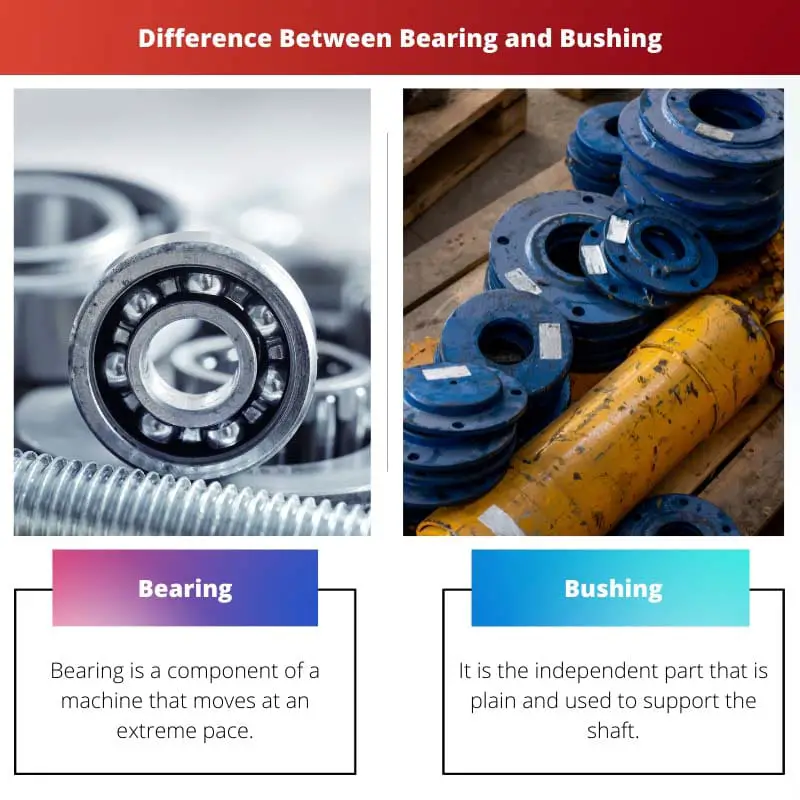

Bearings are machine elements that allow parts to move relative to each other, reducing friction between moving parts and facilitating smooth movement. Bushings, also known as plain bearings, are a type of bearing that provides a sliding interface with low friction and wear, used in applications with limited space.

Around the turn of the nineteenth century, the bearing was redesigned into its current shape. Initially, it was made by hand. Bearings are one of the most widely used machine parts nowadays because their rolling motion simplifies and lowers friction in almost all activities.

Thus, they are getting used to in limitless numbers of machines.

A bushing is a specific type of bearing. Although the design is simple, the material utilized significantly impacts the bushing’s performance and function.

A bushing, on the other hand, is a self-contained plain bearing that supports a shaft and moves back and forth between the moving surfaces. Bushings made of plastic.

Comparison Table

| Parameters of Comparison | Bearing | Bushing |

|---|---|---|

| Fundamental | Bearing is a component of a machine that moves at an extreme pace. | It is the independent part that is plain and used to support the shaft. |

| Function | Bearing is also used for the purpose to reduce friction. | The bushing is required because it operates the motion of two already moving interfaces. |

| Composition | The bearing consists of two parts that make it whole. | The bushing is a single-piece element. |

| Category | Bearing does not belong to the bushing category. | Bushing certainly belongs to the bearing category. |

| Application | Bearing is used in many types of vehicles | The bushing is used in the suspension machines of the vehicle. |

What is Bearing?

The bearing was created in its current form around the end of the nineteenth century. It was produced by hand at first.

Bearings are one of the most extensively utilized machine parts nowadays since their rolling motion simplifies practically all actions and reduces friction.

Bearings have two primary purposes:

They transmit motion by supporting and guiding components that rotate in relation to one another.

They are responsible for transmitting forces.

Sleeve bearings and rolling bearings

The axle and the bearing travel in opposite directions on a sliding surface in a sleeve or plain bearing. On the other hand, the inner and outer rings of a rolling bearing move towards one another and are separated by rolling elements.

Compared to a sleeve bearing, this design produces substantially less friction.

Axial bearings and radial bearings are two types of bearings. Bearings may transport loads in both radial and axial directions (push), and in many circumstances, both radial and axial loads must be transmitted.

Ball bearings and roller bearings are available in both configurations. The application determines the bearing to use.

What is Bushing?

A bushing is a particular kind of bearing. Although the design is basic, the performance and function of a bushing are highly dependent on the material used. Bushings made of bronze

Bronze bushings have a long service life and are extremely durable. They don’t rust and don’t distort readily. Bronze bushings, on the other hand, require a lot of oil during operation, making them more difficult to maintain than plastic bushings.

Plastic bushings made of plastic are popular because they are inexpensive, have little friction, and need little maintenance.

They are self-lubricating, making them ideal for hard-to-reach sections, and they are corrosion-free, allowing them to be utilized in moist settings.

We examine the advantages and disadvantages of using plastic as a bearing material.

Plastic bushings offer several operational benefits. They are maintenance-free and have a low coefficient of friction since they are self-lubricating.

Plastic is ideal for basic plain bearings since it minimizes weight and maintenance while also preventing brinelling. However, we’re witnessing a rise in the use of plastic ball bearings and bushings.

Bushings are self-contained plain bearings made up of multiple distinct materials that are integrated to form a single load-bearing component.

Main Differences Between Bearing and Bushing

- The contrast between bearings and bushings is a kind of bearing. Bearings are a generic term for anything that allows motion between two components. Bushings are specific pieces of equipment. Bushings are composed of a single component, unlike rolling-element bearings.

- Bearing is also used for the purpose of reducing friction, whereas Bushing is required because it operates the motion of two already moving interfaces.

- The bearing consists of two parts which make it whole, whereas Bushing is a single-piece element that is an independent element to work. Bushings are self-contained plain bearings made up of multiple distinct materials that are integrated to form a single load-bearing component.

- Bearing does not belong to the bushing category. It is an important part of a machine on its own, whereas Bushing certainly belongs to the bearing category. It is one of the types of bearing

- Bearing is used in many types of vehicles, whereas Bushing is used in the suspension machines of the vehicle and many other machines where it plays different roles.