Chain Drive and Belt Drive are essential parts and types of mechanisms. It adds the advantage of locomotion and transfer of power. The primary utilization is to shift the ability to move objects. Both are used in many vehicles. Chain Drives and Belt Drives are used in automobiles.

Key Takeaways

- Chain drives are used in heavy-duty applications that require high-power transmission, whereas belts are used in low-power transmission applications.

- Chain drives have higher efficiency and are more reliable in harsh conditions, while belts are less efficient and less durable.

- Chain drives are noisier than belt drives, requiring regular lubrication, whereas belt drives do not require lubrication and are quieter.

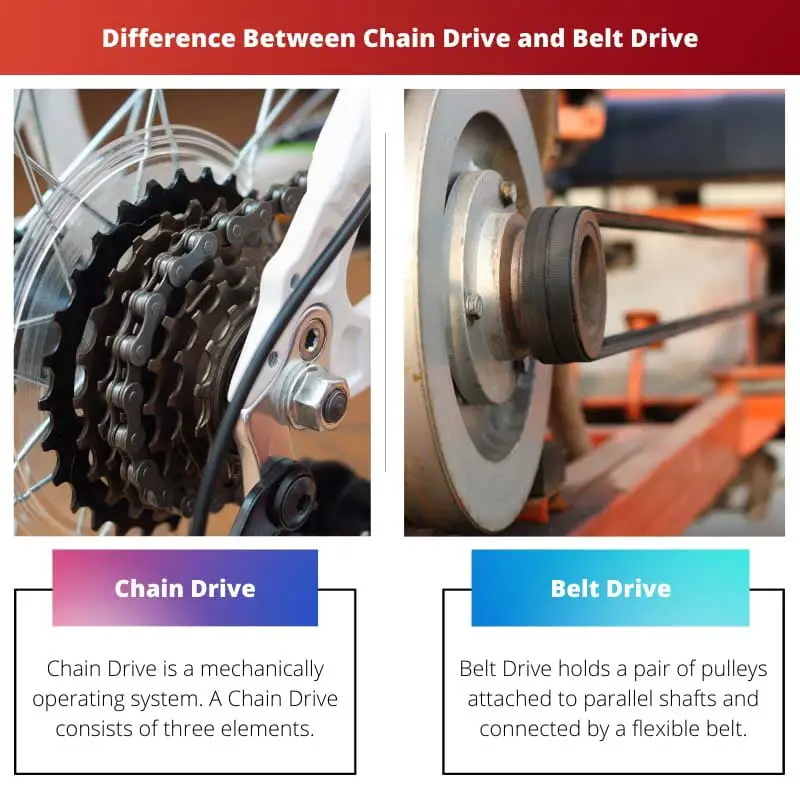

Chain Drive vs Belt Drive

Chain drives use metal chains and sprockets to transmit power and are more robust and durable but noisier and require more maintenance. Belt drives use flat belts and pulleys and are quieter, more efficient, and require less maintenance, but they are also less durable and can slip under high loads.

Chain Drive has strength and durability as it is made from metal. It comprises chains with a unique teeth-like surface on one side, and an etch on the other. The designs allow the chain to hold it in one place and direction.

Belt Drive is made of a smooth synthetic material. It can be made from other artificial substances. It is best used for machines and useful in inspection for damage or wear. It requires fewer adjustments and runs smoothly as compared to a chain drive.

Comparison Table

| Parameters Of Comparison | Chain Drive | Belt Drive |

|---|---|---|

| Main Element | Sprockets, chain | Pulleys, belt |

| Slip | No-slip | Slip may occur |

| Space | Moderate space | Large space |

| Life | Moderate Life | Less Life |

| Suitability | Moderate centre distances | Large centre distances |

| Lubrication | Required | Not required |

| Design | Simple | Simplest |

| Installation Cost | Moderate | Less |

| Type | Engagement Drive | Friction Drive |

| Workroom Temperature | Not affected | Affected |

What is Chain Drive?

A chain Drive is a mechanical operating system. A Chain Drive consists of three elements. They have driven sprockets, driving sprockets, and a chain wrapped around driven and drive sprockets. It has no slipping and provides positive transmission. It provides a positive drive as it is free from slip.

It produces a constant velocity ratio.

There are three types of chains. They have four chains: hauling chains, conveyor chains, power transmission chains, and hoisting chains. It is used in bicycles, motorcycles, agricultural machinery, and textile machinery, material handling equipment.

A Chain Drive consists of a roller chain, silent chain, detachable link chain, double pitch chain, and engineering steel chain. There are various types of load classification. They are moderate shock load, smooth load, and heavy shock load. The chain Drive is more robust and more durable.

It is easier to change gears when the chain is broken.

Chain Drivers contain two gears. A Chain Drive is used when the distance between the power produced and where it has to be transferred is less. Chain Drives are used for longer distances power transfer.

The speed ratio remains constant in Chain Drive. Chains are run over a wheel which is known as a Sprocket. It has numerous teeth around the circumference. Chain Drive requires moderate space.

What is Belt Drive?

Belt Drive holds a pair of pulleys attached to parallel shafts and connected by a flexible belt that can transmit and modify rotary motion from one post to the other. The main elements are pulleys and belts. It is looped over pulleys and has twists between pulleys.

The shafts need not be parallel. Belt Drive is the most flexible element of the mechanical system. There are five types of Belt Drive: open belt drive, closed or crossed belt drive, fast and lose cone pulley, stepped cone pulley, and jockey pulley drive. It is a non-positive drive because of slip and creep.

The material used in the belt should be chosen based on properties like flexibility, liability, durability, and resistance to temperature.

Five types of material are available for the belt: leather, rubber, cotton or fabric, plastic, and balata. It is used to change the rotation speed directly or use different-sized pulleys.

The power transmitted by the system depends on factors like the belt’s velocity, tension, the arc of contact, and other conditions under which the belt is used in the mechanical system. Belt Drive has the most straightforward design, manufacturing, and complexity.

Belt Drive does not require any lubrication.

Main Differences Between Chain Drive and Belt Drive

- A chain loop operates Chain Drive, whereas a belt operates Belt Drive.

- Metals are used in the formation of Chain Drive. On the other hand, belt drives are made of synthetic materials.

- Slips may occur in Belt Drive, but there is no slip in Chain Drive.

- The belt drive has less life span as compared to the Chain drive.

- Lubrication is required in Chain Drive, whereas Belt Drive does not require lubrication.

- Belt Drives require large space, whereas Chain Drives require moderate spaces.