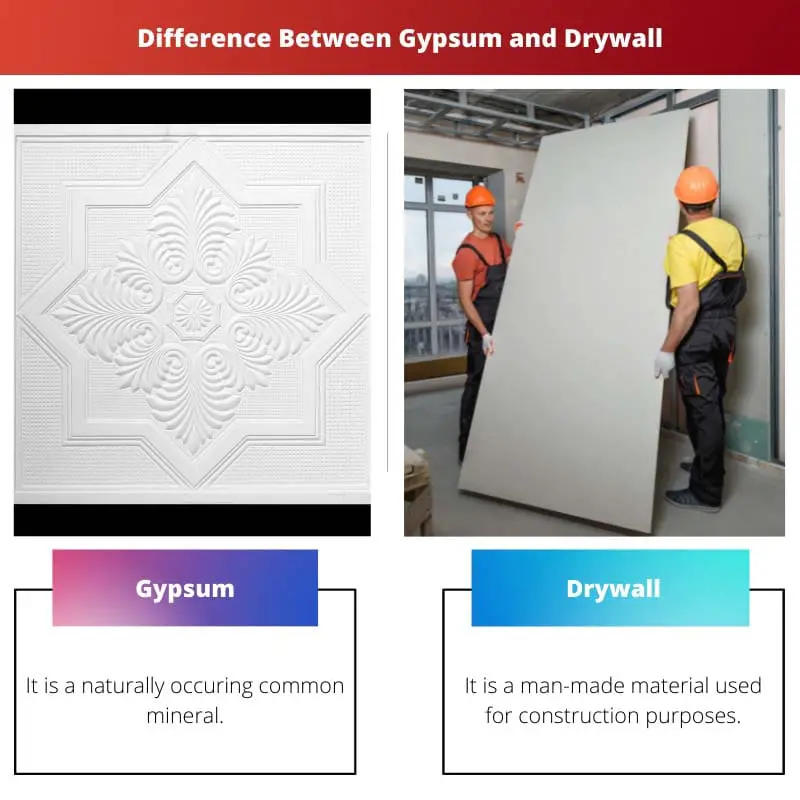

Gypsum is a naturally occurring mineral comprising calcium sulfate dihydrate, used for making plaster and as a soil conditioner. Drywall, on the other hand, is a manufactured building material composed of gypsum plaster sandwiched between two layers of paper.

Key Takeaways

- Gypsum is a mineral commonly used in the construction industry to make plaster and cement.

- Drywall, also known as plasterboard, is a type of building material made from gypsum used to create walls and ceilings in homes and buildings.

- Gypsum is a natural mineral mined from the earth, while drywall is a manufactured product produced in large sheets and then cut to size for use in construction.

Gypsum vs. Drywall

The difference between gypsum and drywall is that gypsum is a naturally occurring natural mineral used for construction work. At the same time, drywall is a manufactured product with gypsum as one of its raw materials. A lot of properties of the drywall are because of the gypsum plaster present in it.

Gypsum is a naturally occurring prevalent mineral found in layered sedimentary deposits. It is composed of calcium sulfate, i.e., CaSO4.2H2O, and has very high commercial importance.

Gypsum is derived from the Greek word “gipsies” meaning plaster. It is partially soluble in water, but at high temperatures, it becomes less soluble.

Drywall is a human-made material that is used for the application of walls without using the materials like mortar or plaster. It is also known as wallboard and comprises gypsum plaster and paper.

Drywall is sometimes used as a sheathing material for covering the exterior of a building.

Comparison Table

| Feature | Gypsum | Drywall |

|---|---|---|

| Material | Mineral | Finished building panel |

| Composition | Calcium sulfate dihydrate (CaSO4·2H2O) | Gypsum plaster sandwiched between paper or fiberglass facings |

| Use | Raw material for various construction applications | Final wall surface |

| Examples | Drywall, plaster, joint compound | Walls, ceilings |

| Advantages | Fire-resistant, soundproofing properties | Easy and fast to install, cost-effective |

| Disadvantages | Requires skilled labor for traditional plaster applications | Less durable than traditional plaster, can be susceptible to damage from moisture |

What is Gypsum?

Gypsum is a naturally occurring mineral with various industrial applications, prized for its versatility and unique properties. It is composed of calcium sulfate dihydrate and is commonly found in sedimentary rock formations. Gypsum deposits can occur as large rock formations or in finely granulated forms.

Chemical Composition and Structure

- Chemical Formula: CaSO₄ · 2H₂O

- Structure: Gypsum crystals form as monoclinic prisms or flat plates, exhibiting a translucent to transparent appearance. The mineral contains water molecules within its structure, leading to its designation as calcium sulfate dihydrate.

- Solubility: Gypsum is moderately soluble in water, meaning it can dissolve to some extent, particularly in acidic conditions.

Industrial Applications

- Construction Industry: Gypsum is widely used in the construction industry for various applications, including:

- Plaster: When gypsum is calcined (heated to remove water molecules), it forms plaster of Paris, a versatile material used for creating molds, sculptures, and decorative elements.

- Drywall: Gypsum is a key component in the production of drywall, also known as plasterboard or wallboard. Drywall panels consist of a gypsum core sandwiched between layers of paper or fiberglass, providing an efficient and cost-effective solution for interior wall and ceiling construction.

- Cement: Gypsum is added to cement formulations to control setting time and improve workability. It acts as a retarder, slowing down the hydration process to allow for better handling and placement of the concrete mixture.

- Agriculture:

- Soil Amendment: Gypsum is utilized as a soil conditioner to improve soil structure and fertility. It helps to break up compacted soils, increase water infiltration, and enhance nutrient availability for plant uptake. Additionally, gypsum can mitigate soil salinity and sodicity issues, promoting healthier plant growth.

- Industrial Processes:

- Industrial Uses: Gypsum finds applications in various industrial processes, including the production of plasterboard, cement, fertilizer, and as a filler in paper and textiles manufacturing.

- Environmental Remediation: Gypsum can be used in environmental remediation efforts, such as soil and water treatment, to reduce the concentration of certain contaminants through processes like adsorption and precipitation.

Environmental Considerations

- Sustainability: Gypsum is considered a relatively sustainable material, as it is abundant in nature and can be recycled multiple times in various industrial processes.

- Disposal: Proper disposal of gypsum waste is essential to prevent environmental contamination, particularly in cases where gypsum contains impurities or contaminants.

What is Drywall?

Drywall, also known as plasterboard or wallboard, is a commonly used building material in interior construction. It consists of a gypsum core encased between two layers of paper or fiberglass. Drywall panels are lightweight, easy to install, and provide a smooth and durable surface for walls and ceilings in residential, commercial, and industrial buildings.

Composition and Structure

- Gypsum Core: The core of drywall is composed of gypsum plaster, which is a naturally occurring mineral consisting of calcium sulfate dihydrate. This gypsum core provides rigidity and stability to the drywall panel.

- Facing Material: Drywall panels are covered on both sides with facing material, which can be paper or fiberglass. The facing material serves to protect the gypsum core from damage, provide a smooth surface for finishing, and improve fire resistance and sound insulation properties.

Manufacturing Process

- Gypsum Preparation: Gypsum is mined from natural deposits or obtained as a byproduct of industrial processes. The raw gypsum is crushed and ground into a fine powder.

- Formulation: The powdered gypsum is mixed with water to form a slurry, which is then poured onto a continuous sheet of facing material.

- Sandwiching Process: Another layer of facing material is applied on top of the wet gypsum slurry, sandwiching it between the two layers of facing material.

- Drying and Cutting: The assembled panels are passed through drying ovens to remove excess moisture, ensuring proper curing of the gypsum core. Once dried, the panels are cut into standard sizes and ready for packaging and distribution.

Applications and Advantages

- Interior Construction: Drywall is widely used in interior construction for walls and ceilings in residential, commercial, and industrial buildings. It provides a smooth and uniform surface for painting, wallpapering, or other decorative finishes.

- Ease of Installation: Drywall installation is relatively quick and straightforward compared to traditional plaster-based wall systems. The lightweight nature of drywall panels makes handling and installation easier, reducing labor costs and construction time.

- Fire Resistance: Gypsum, the primary component of drywall, offers inherent fire resistance, making drywall panels effective in slowing down the spread of flames in case of fire. Additionally, fire-resistant drywall variants with enhanced fireproofing properties are available for specific applications.

- Sound Insulation: Drywall panels help to reduce sound transmission between rooms, improving acoustic comfort within buildings. Thicker drywall panels and the addition of soundproofing materials further enhance sound insulation properties.

Environmental Considerations

- Recyclability: Drywall is recyclable, and gypsum waste generated during construction or demolition can be processed and reused in new drywall production or other applications.

- Energy Efficiency: Drywall manufacturing processes have become more energy-efficient over time, reducing the environmental impact associated with production.

Main Differences Between Gypsum and Drywall

- Composition:

- Gypsum: Naturally occurring mineral composed of calcium sulfate dihydrate.

- Drywall: Building material consisting of a gypsum core sandwiched between two layers of paper or fiberglass.

- Application:

- Gypsum: Used in various industries for purposes such as making plaster, soil conditioning, and industrial processes.

- Drywall: Primarily used in interior construction for walls and ceilings in residential, commercial, and industrial buildings.

- Form and Function:

- Gypsum: Can exist as a mineral deposit or finely granulated form, utilized in its natural state or processed for various applications.

- Drywall: Manufactured building material with specific dimensions and properties, designed for easy installation, providing a smooth and durable surface for finishing interior walls and ceilings.