Glowforge and K40 are both CO2 laser cutters which use a 40 W laser to cut or engrave designs on different materials like wood, fabric, rubber, leather, paper, and many others.

Glowforge uses subtractive manufacturing, and K40 uses concentrated light to cut the materials in 2D. Both of the cutters are quite similar in many parameters like cooling system, beam power, tech, etc., but these two cutters are very different in terms of features and functionality.

Key Takeaways

- Glowforge is a user-friendly and user-friendly laser cutter, whereas K40 is a DIY laser cutter kit.

- Glowforge provides cloud-based software for designing, whereas K40 requires external design software.

- Glowforge is expensive but offers advanced features, whereas K40 is affordable but requires additional modifications for advanced features.

Glowforge vs K40

The difference between Glowforge and K40 is that the former is a bit more expensive than the latter one. Glowforge can cut deeper and larger areas of the materials than the K40 cutter. The K40 cutters are manufactured by various companies, and all have different minor features. And Glowforge is of three types which are Glowforge basic, Glowforge Plus, and Glowforge Pro.

Glowforge is a laser printer, as said by the brand, but in literal meaning, it is a laser cutter and engraver that uses a high beam of laser light to carve designs on different materials.

It can accommodate materials up to 18” deep, 20.4” wide, and 2” tall. It is compatible with any type of file format to print, like PDF, JPG, PNG, SVG, and others.

K40 is a 40 W laser cutter or engraver which is not manufactured by any single official company nor does it has a specific design structure, but all K40 cutter perform the same function.

It is an affordable laser cutter that got its name because it uses a 40 W laser tube. The tuned one can cut up to 1/4 inch of any material, and the one without any tuning can cut up to 1/8 inch of any material.

Comparison Table

| Parameters of Comparison | Glowforge | K40 |

|---|---|---|

| Maximum cutting area | 11 x 19.5 inches | 12 x 8 inches |

| Interface compatibility | Mac, PC, Windows, tablets, and more | Mac, Windows, and linux |

| Software used | Glowforgenative software | K40 Whisperer |

| Weight | 55 lbs | 50.6 lbs |

| Operating temperature | 60° -70° F | 59° -77° F |

What is Glowforge?

Glowforge is a laser cutter and engraver which uses a high beam laser light to cut or engrave designs on any material ranging from wood, rubber, leather, paper, and acrylic to foods and phones, laptops, and others.

The dimensions of the whole machine are 38″ wide x 20.75″ deep x 8.25″ tall. It accepts all types of file formats, and designing can be done with any software that can save it in a PDF, like Adobe Illustrator, Inkscape, CorelDraw, Adobe Photoshop, GIMP, Autodesk 360, and Sketchup.

It is compatible with all the systems which have an up-to-date browser. It uses the Glowforge native software to operate. To use it, there are two simple steps: create an account and set it up.

Glowforge has a good customer support community that solves problems instantly. Glowforge has three models of laser cutters which are Glowforge Basic, Glowforge Plus, and Glowforge Pro.

The difference between the three models is about each laser’s speed and strength. All the Glowforge units are manufactured by Flex which is known to be amongst the best manufacturing companies around the world.

This laser cutter machine is very easy to use and takes less than 30 minutes to set the whole thing.

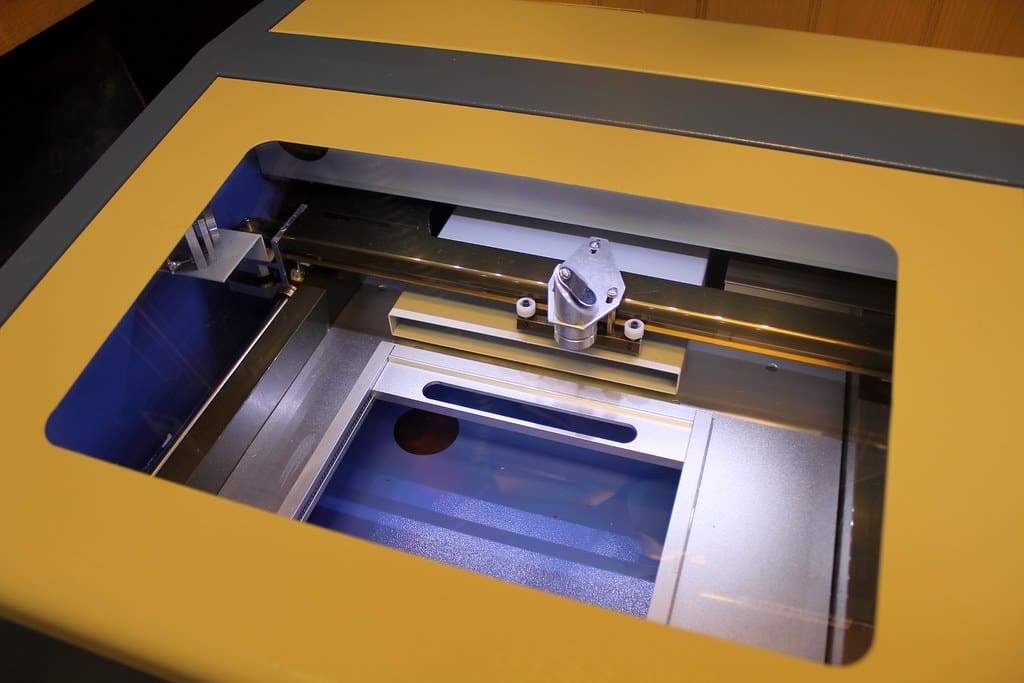

What is K40?

K40 is any laser cutter that uses a 40 W laser beam to cut or engrave designs on any type of material placed in it. K40 is not a specific model type.

Neither is it manufactured by a single manufacturer. All the K40 laser cutters come in different sizes and shapes as the manufacturer changes, but the essence of all K40 laser cutters is the same.

K40 is compatible with Mac, Windows, and Linux. K40 cutters do not fall under easy plug-and-play machines. It requires some assembly activity before usage. These machines have high voltage and powerful lasers, and thus, they should be used very carefully, taking all the precautions properly.

All the K40 laser cutters consist of components, namely a CO2 laser tube made of glass, stepper motors, a control board with a power supply, an exhaust fan, and a coolant pump.

With no upgrades or tunings, the K40 laser cutter is capable of cutting 1/8 inch of material, and with a few upgrades and a bit of tuning, the machine can cut up to 1/4 inch of any material.

With the different models by the different manufacturers, the software on which it operates differs, but the common software is K40 Whisperer.

Main Differences Between Glowforge and K40

- The maximum area that can be cut with a Glowforge laser cutter is 11 x 19.5 inches, whereas with a K40 laser cutter, the maximum area that can be cut is 12 x 8 inches.

- The necessary condition for using Glowforge laser cutter is that the system should have an up-to-date version of google chrome, Firefox, Apple Safari, or Microsoft Edge, and then it is compatible with any device, be it Mac, Windows, PC, android, tablet or any other device whereas, on the other hand, K40 is compatible with Mac, Windows, and Linux.

- Glowforge laser cutter uses Glowforge native software for operating, and on the other hand, the K40 laser cutter uses a K40 whisperer for operating.

- The Glowforge laser machine weighs nearly 55 lbs, whereas the K40 laser machine weighs 50.6 lbs.

- The operating temperature range for Glowforge laser cutter is between 60 ° to 70° F, and on the other hand, the operating temperature range for K40 laser cutter is between 59 ° to 77 ° F.