Reciprocating and rotary pumps are the most common and efficient types of pumps. They both use an inlet valve to change the direction of flow.

The inlet valves allow the pump to move fluid from one point to another, but only if they are moving consistently.

Key Takeaways

- Reciprocating pumps have a reciprocating motion, while rotary pumps have a rotational motion.

- Reciprocating pumps have a higher pressure range and are suitable for high-pressure applications, while rotary pumps are better for low-pressure applications.

- Reciprocating pumps are more complex and require more maintenance than rotary pumps, which are simpler and require less maintenance.

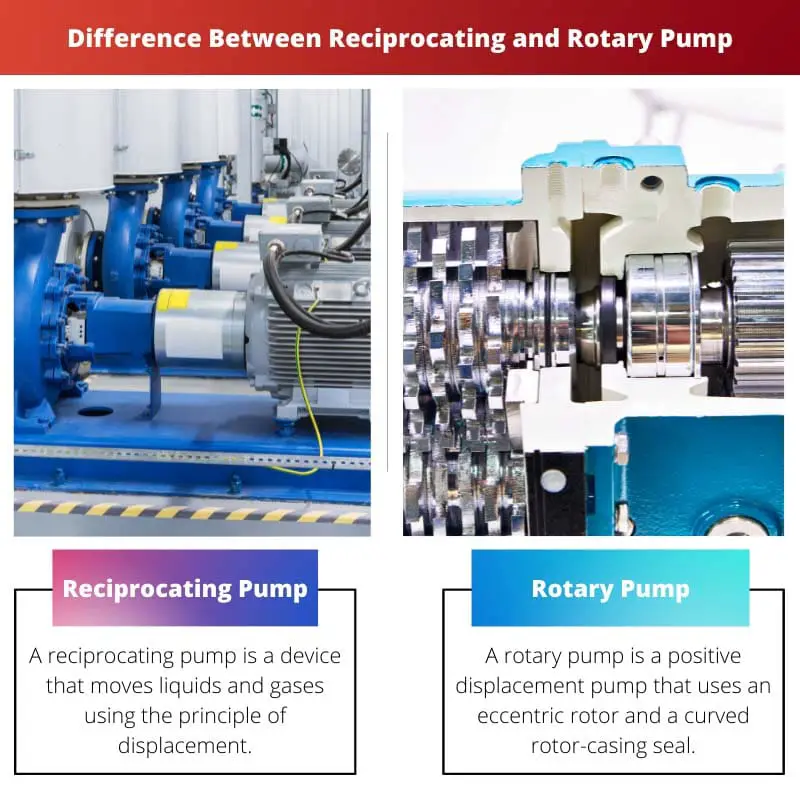

Reciprocating vs Rotary Pump

A reciprocating pump is a machine that is used to carry both liquids and gases by using the principle of displacement, and they include radial pistol pumps and plunger pumps. A rotary pump Is a machine that consists of a displacement pump, and it uses a curved rotor and an eccentric rotor.

A reciprocating pump engine is the most popular type of internal combustion engine. The reciprocating pump was an important technological development in the history of water supply.

It moves liquids like water or oil by the use of pressure pulses to push against liquid flow through nonreturn valves. The reciprocating pump uses a plunging plunger to create pressure and lift liquids.

The Rotary pump is a positive displacement device that consists of a rotor with several blades attached to a shaft. Which in turn is coupled to a tubular housing.

The rotor turns within the housing as the blades rotate. Causing fluid to be drawn in from an inlet port and discharged through an outlet port.

Comparison Table

| Parameters of Comparison | Reciprocating Pump | Rotary Pump |

|---|---|---|

| Size | Large | Small |

| High-Pressure liquids | Good | It needs to be adjusted |

| Types | Plunger pumps, Radial Pistol pumps | Screw pumps, Lobe pumps, Gear pumps |

| Space | More | Less |

| Maintenance | High | Low |

| Flow | Pulsating | Smooth |

What is Reciprocating Pump?

A reciprocating pump is a device that moves liquids and gases using the principle of displacement. Fluid is drawn into the pump cylinder, accelerated to a high velocity, and ejected from the cylinder.

The result is similar to that produced by a centrifugal pump, but in a reciprocating pump, pressure forces liquid. T flow through valves and pipes rather than centripetal force.

The pump was powered by steam engines, enabling cities to bring water from greater distances. It was a key contributing factor to the population growth of urban areas.

The Industrial Revolution opened up new possibilities for agriculture as well. A reciprocating pump is a positive displacement pump.

It moves liquids like water or oil by the use of pressure pulses to push against liquid flow through nonreturn valves, which are used to increase efficiency.

The first piston pumps were hand-operated and date back to the first century AD. They were developed in China during the Han Dynasty (206 BC–220 AD).

The Chinese engineer Ding Huan created what he called the ‘Spring and Well’ pump. This consisted of a flowing well with an underground tube attached below it.

This tube was connected to two J-shaped pistons that moved up and down inside.

What is Rotary Pump?

A rotary pump is a positive displacement pump that uses an eccentric rotor and a curved rotor-casing seal. It produces a variable vacuum in the pumping chamber, drawing in the fluid.

There are two types of rotary pumps: centrifugal and peristaltic pumps. These pumps work on slightly different principles but achieve the same result: transferring fluid from one to another.

Rotary pumps are a group of positive displacement pumps commonly used to pump liquids with viscosities ranging. From 1.5 centipoises (0.007 mils) for lower volume applications.

Using an open impeller up to 35,000 centipoises (0.78 mils) for high volume applications using a closed impeller. It can be designed to handle a wide range of volumes at low power consumption.

There are two basic types of rotary pumps: volumetric and flow rate. A rotary pump (also known as a helical pump) is a positive-displacement type of internal gear pump.

The pistons within the pump rotate, and this rotation causes the fluid to move through the rotary pump. The rotary pump can be used in various industries to transport materials.

That is difficult to move using more conventional methods of transportation. These pumps have been designed for special applications.

That requires more precise control of pressure or volume than other types of pumps provide.

Main Differences Between Reciprocating and Rotary Pumps

- Reciprocating pumps are larger than Rotary pumps.

- The reciprocating pump is good with high-pressure liquids, but the Rotary pump has to adjust the pressure.

- Reciprocating pumps are plunger pumps, radial pistols, and many more, but Rotary pumps are screw pumps, lobe pumps, gear pumps, and many more.

- Reciprocating pumps need more space compared to Rotary pumps.

- Reciprocating pumps need high maintenance compared to Rotary pumps.

- The flow is pulsating in reciprocating pumps but smooth in rotary pumps.