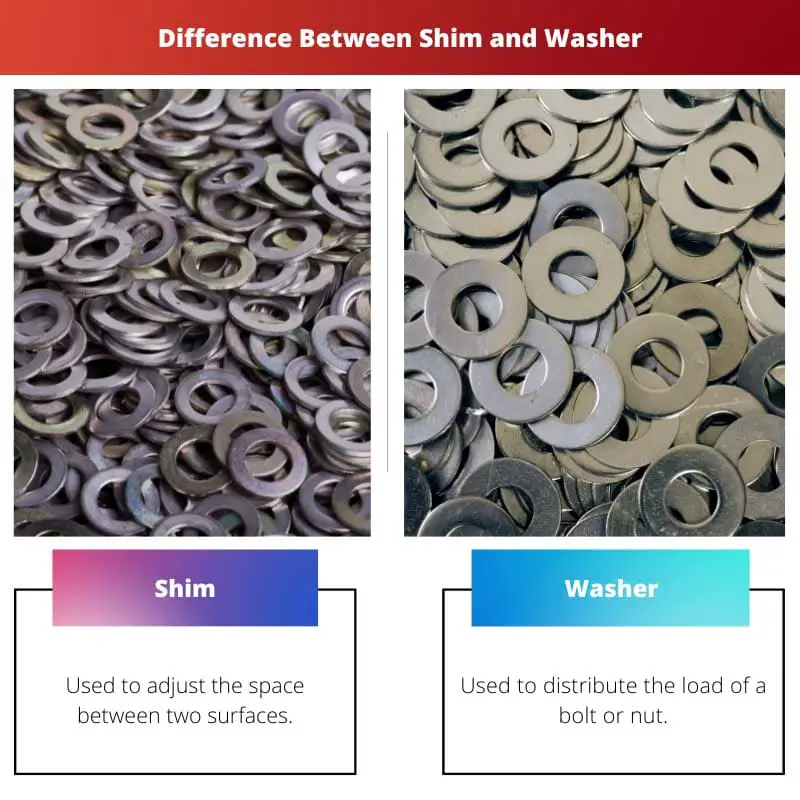

Shim and Washer might seem the same, but when used in the real world are completely different. These tools serve different purposes, and at times, one can be more beneficial than the other.

In simple words, Shim is used to adjusting the gap, and Washer is used to distribute the load of screws/nuts.

Key Takeaways

- A shim is a thin, flat material that adjusts the space or alignment between two components. At the same time, a washer is a flat, ring-shaped material designed to distribute the load, reduce friction, or prevent leakage when placed between a bolt or screw head and the surface being fastened.

- Shims are primarily used to achieve precise spacing or alignment in various applications, whereas washers serve multiple purposes in fastening and assembly.

- Shims and washers are essential hardware components used in various industries and applications, contributing to assembled parts’ functionality and stability.

Shim vs Washer

A shim is used to fill the gap between surfaces or objects. Different materials can be used to make shim. Shim can be made of wood, stone, or many other materials. A shim is also used in the automobile industry. A washer can be used as a locking device. A washer is made of metal or plastic. There are three main types of washers.

A shim is a thin tapered piece of material that is used to adjust the space between two objects. A shim can be made up of various materials such as wood, metal, plastic, and stone. An object subject to wear and tear is prevented for so using a shim.

A washer is shaped like a thin plate or doughnut-shaped with an outer radius bigger than the inner one. The small hole structure helps to distribute the load of a screw or nut.

When a washer is used, there is a lesser or negligible chance for the fastener to break into a heavyweight situation.

Comparison Table

| Parameters of Comparison | Shim | Washer |

|---|---|---|

| Definition/purpose | Used to adjust the space between two surfaces | Used to distribute the load of a bolt or nut |

| Material used | Wood, metal, plastic, stone | Metal, plastic |

| Shape | Wedged or tapered or any shape | donut |

| Contribution to reducing friction | Prevents wear and tear | Prevents the fastener to break |

| Commercial use | laminated | Steel |

What is Shim?

Shim is a thin material whose shape depends on the space where it is to be used. It helps in the prevention of wear and tear by levelling the surface.

High-quality shims are available for commercial purposes in laminated form, but in practical life, a shim is made at the spot to level an uneven surface.

In the automobile industry, shims are placed between the bucket tappets controlling the valve clearance, which can further be adjusted by thinning or thickening the shim.

In the assembly of any object, precision metal shims are used to furnish the finalized product in the way specified by the product’s drawing specialist. In machinery installations, shims are required to adjust motors, pumps, etc., flexibility.

The most common situation to observe the importance of shim is carpentry. During the construction of wooden structures, small pieces of wood are used to fill the gaps between large timbers.

Musicians also use a shim to adjust the pitch and tones of their musical instruments. CPU shims are used to prevent heat sinks in the central processing unit of printed circuit boards.

Shims are used to obtain pure Lorentzian line shapes with differing spectrums. My manual shimming of individual shims or automatic shimming process does this.

What is Washer?

A washer is a disk-shaped material that distributes the load concentrated on a screw or bolt, or nut. It is used as a spacer, locking device, reduces vibration or friction, wears and tear, or as an insulating device.

The first use of a washer was recorded in 1346, but the proper definition was explained back in 1611, as reported.

High-quality hardened steel washers are used to prevent pre-load caused due to brinelling (permanent indentation of a surface) after torque is applied.

They are also used to prevent galvanic corrosion by insulating the surface. Lubrications or coatings are done to tackle wear and tear.

Washers are used in tube wells for the smooth drawing of water from underground. Washers are mistaken for gaskets which are used as a seal against water leaks.

Washers can be divided into three types – Plain washers, spring washers, and locking washers.

Plain washers – spread the load and prevents damage to fixed surfaces by providing insulation. For example, electrical. An anchor plate or wall washer also comes under this category.

Spring washers have axial flexibility and prevent fastening or loosening caused due to vibrations. It is also called a Belleville washer or cupped spring washer, or conical washer (depending on its shape).

Other types of Spring washers are curved disc springs, wave washers, tab washers, and wedge lock washers.

Locking washers – prevents fastening or loosening caused by the rotation of the fastening device or over time.

Spring and locking washers are similar in some cases.

Main Differences Between Shim and Washer

- Shim is used to provide an even surface by filling the gaps and supporting the structure, whereas the washer is paired with a screw or bolt or nut to increase the system’s durability.

- Shim has no specific type rather comes in different shapes, instantly made considering the gap, whereas washers come in three types depending on torque, rotation, friction, or vibration.

- Shim can be a wooden block, a steel plate, a small plastic piece, etc., whereas a washer is available in the form of metal or plastic only.

- Shim might be needed in any everyday lifehacks, whereas washers are specially used in the automobile industry or construction sites.

- There is no specific year when the use of shim was first observed, whereas a washer has been recorded to be used since 1346.

- https://journals.lww.com/implantdent/FullText/2012/04000/Effect_of_Using_a_Titanium_Washer_on_the_Removal.15.aspx

- https://journals.sagepub.com/doi/abs/10.1177/0954406215622496