There are many methods when it comes to joining various kinds of metals and processing them. This process includes many known and unknown methods, which are very essential and must be well understood by people.

Two such methods are welding and soldering. Although both do the same work, they have vast differences.

Key Takeaways

- Welding is a process of joining two metals by heating them to a high temperature and melting them together, while soldering is joining two metals by heating them to a lower temperature and using a filler metal.

- Welding produces a stronger bond and is used for larger and thicker materials, while soldering is used for smaller and more delicate materials.

- Welding requires more skill and expertise than soldering, and it involves a higher risk of injury or damage to the materials.

Welding vs Soldering

In welding, two metals are heated together at high temperatures, and then they are combined to produce a stronger bond necessary for the thickness of an object. Soldering involves heating two metals at low temperatures and adding another metal in it as a filler. This process is used for light things.

The process which is used for creating a really strong bond between any two metals is known as welding. The piece of metals that have been joined will be Resistant to any strain or stress. This practice is mostly seen in the automobile industry.

Pieces of metals being the same, heated with high temperature, etc., are some features necessary for welding.

The process of soldering does relate a lot to welding, but it has Its features too. First, it is a process used for not only connecting two metals but also two kinds of electronic components together.

The machine of solder is available in tubes or the shape of a pipe. Setting low temperatures and availability of flux are some necessities of soldering.

Comparison Table

| Parameters of Comparison | Welding | Soldering |

|---|---|---|

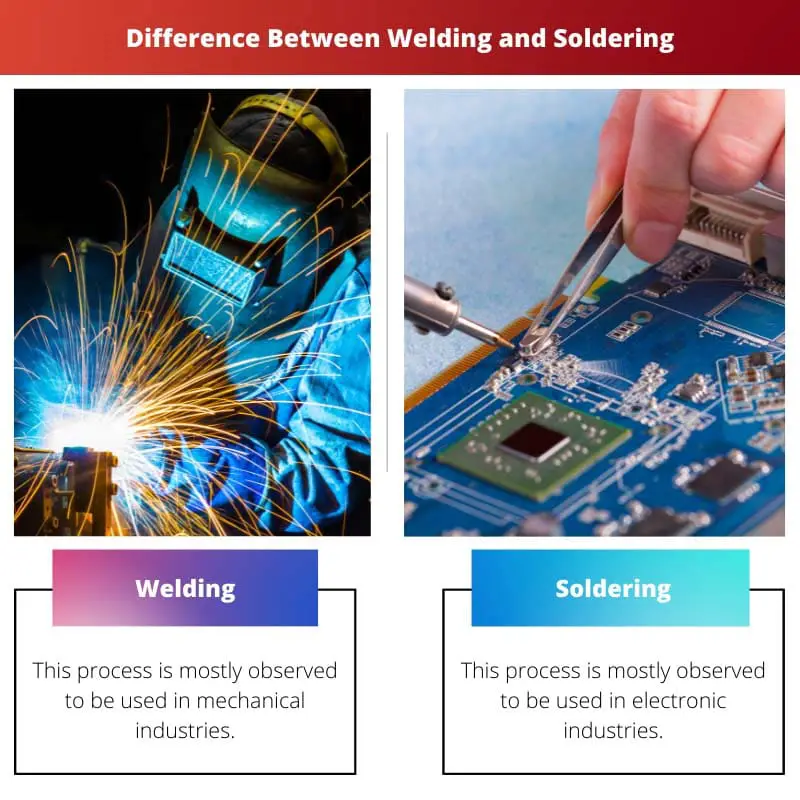

| Use | This process is mostly observed to be used in mechanical industries. | This process is mostly observed to be used in electronic industries. |

| Temperature | The temperature of welding is set higher than the melting temperature. | The temperature of welding is set lower than the melting temperature. |

| Type of joint | This process helps the metals to become strong mechanical joint. | This process helps the metals become strong electronic joint. |

| Use of filler | There is no compulsion for using filler metal in this process. | There is a compulsion for using filler metal in this process. |

| Properties of metals | There occurs a change in the properties of metals. | There does not occur any changes of properties in metals. |

What is Welding?

When there is a process of welding between two metals, those two metals have to be of the same type, welding cannot take place when there are two different metals. For example, stainless steel cannot be welded with brass.

The welding process is basically a process that allows to join of two metals by heating and setting them to a temperature that allows them to melt.

The welding process is done in such a way that a machine is heated to a high temperature, which helps create a molten metal that helps to join two metals together.

Sometimes, a weld pool is made by using a filler metal which helps the metal to join even stronger and more durable.

When two metals are welded, they are even stronger than wherein their original form before the welding process took place.

At the same time, if the process of welding was not carried out properly, then it would have affected the properties and characteristics of metal by weakening it. A worker putting more heat than required in metal is an example of wrong welding taking place.

What is Soldering?

The process of soldering is very close to that of the process of brazing. In the process of soldering, two metals join with a low set temperature instead of a high temperature. In this process, sometimes fillers are also used.

When a melting part cools down on its own mixes and joins into a metal.

When two metals are joined through the process of soldering, they are not as strong as their original version before they were soldered. There are many varieties of how metals can go through this process, namely soft soldering, silver coating soldering, etc.

These different types of soldering processes include having their own characteristics.

The process of soldering is also used to help clean the metals and give them their characteristics and features. It enhances their mental properties.

This process is commonly used for repairing and plumbing and making jewellery.

This process doesn’t make the metal strong but does help to join the metals properly.

Main Differences Between Welding and Soldering (With Table)

- The process of welding is mostly observed to be used in mechanical industries, and on the other hand, the process of soldering is mostly observed to be used in Electronic industries.

- In the process of welding, the temperature of welding is set higher than the melting temperature, and on the other hand, in the process of soldering, the temperature for soldering is set lower than the melting temperature.

- The welding process helps the metals to become strong mechanical joints; on the other hand, the soldering process helps the metals to become strong electronic joints.

- There is no compulsion to use filler metal in the welding process, and on the other hand, there is a necessity to use filler metal in the process of soldering.

- When two metals go through the process of welding, there is a change in their properties of those metals, and on the other hand, when two metals go through the process of soldering, there is no change observed in the properties of those metals.

The detailed discussion of welding and soldering, along with their comparative analysis, provides a comprehensive understanding of these metal joining techniques. It’s an invaluable resource for individuals seeking in-depth knowledge.

The article’s detailed explanation of welding and soldering processes provides a comprehensive understanding of these metal joining techniques. It offers practical knowledge for professionals in the domain.

I agree. The article’s comprehensive coverage of welding and soldering techniques offers essential insights into the differences and applications of these methods.

The article provides a thorough comparison of welding and soldering techniques, highlighting their differences and usage. It emphasizes the importance of understanding these methods for joining metals.

This article succinctly explains the key takeaways of welding and soldering. It’s essential knowledge for anyone working with metals.

I agree with you. It’s crucial to know the differences between welding and soldering to ensure the appropriate application of each technique.

The article’s meticulous exploration of welding and soldering methods offers a rich understanding of these metal joining techniques, serving as an excellent reference for individuals involved in materials processing.

Absolutely. The article’s comprehensive discussion of welding and soldering techniques provides a valuable resource for individuals engaged in metalworking and industrial processes.

The detailed analysis of welding and soldering methods, along with their practical applications, makes this article an essential guide for understanding these metal joining processes.

The article’s description of the welding and soldering processes, along with their applications and characteristics, is highly informative and insightful. It serves as an invaluable resource for professionals and enthusiasts in the field.

The detailed breakdown of welding and soldering techniques, as well as their differences, provides a rich understanding of these metal joining processes. It’s a compelling read for industry professionals.

I completely agree. The article’s comprehensive coverage of welding and soldering is beneficial for individuals seeking to expand their knowledge in the domain of metalworking.

The article serves as a valuable resource for understanding the fundamental differences between welding and soldering. The comparison table effectively highlights the contrasting aspects of these processes.

This article provides a detailed and well-structured explanation of welding and soldering. It’s an excellent reference for those involved in materials processing.

I couldn’t agree more. The discussion on welding and soldering techniques is enlightening and offers a comprehensive view of these metal joining methods.

The comparison table between welding and soldering is very informative, providing a clear understanding of the differences in usage, temperature, type of joint, and use of filler. It’s a valuable reference for those in related fields.

I appreciate the detailed breakdown of parameters in the comparison table. This article offers comprehensive insights into welding and soldering techniques.

Absolutely, the detailed comparison table makes it easy to grasp the distinctions between welding and soldering. It’s a great resource for professionals and enthusiasts alike.

The article effectively explains the process of welding and soldering, emphasizing the importance of temperature, type of joint, and the use of filler. It’s a valuable resource for those seeking in-depth knowledge.

I find the detailed description of welding and soldering processes highly informative. It provides a comprehensive understanding of these metal joining techniques.

This article serves as an excellent guide for understanding the nuances between welding and soldering. It’s essential reading for those involved in metalworking.

The article’s meticulous explanation of welding and soldering methods, along with their application and distinctions, provides a comprehensive understanding of these metal joining techniques. It’s a valuable source for those involved in the field.

The article’s thorough examination of welding and soldering techniques and their applications offers a comprehensive view of these metal joining processes. It’s an instructive resource for individuals in the field.

I share the same perspective. The article effectively captures the nuances of welding and soldering, providing valuable insights for professionals and enthusiasts alike.

The article offers a comprehensive overview of welding and soldering, addressing their usage, temperature requirements, and the types of joints formed. It’s a valuable resource for individuals involved in industrial processes.

I share the same sentiment. The article’s detailed exploration of welding and soldering methods offers a wealth of knowledge for professionals and enthusiasts alike.

The article’s thorough description of welding and soldering serves as an essential guide for understanding the nuances of these metal joining processes. It’s an insightful read for those in related fields.