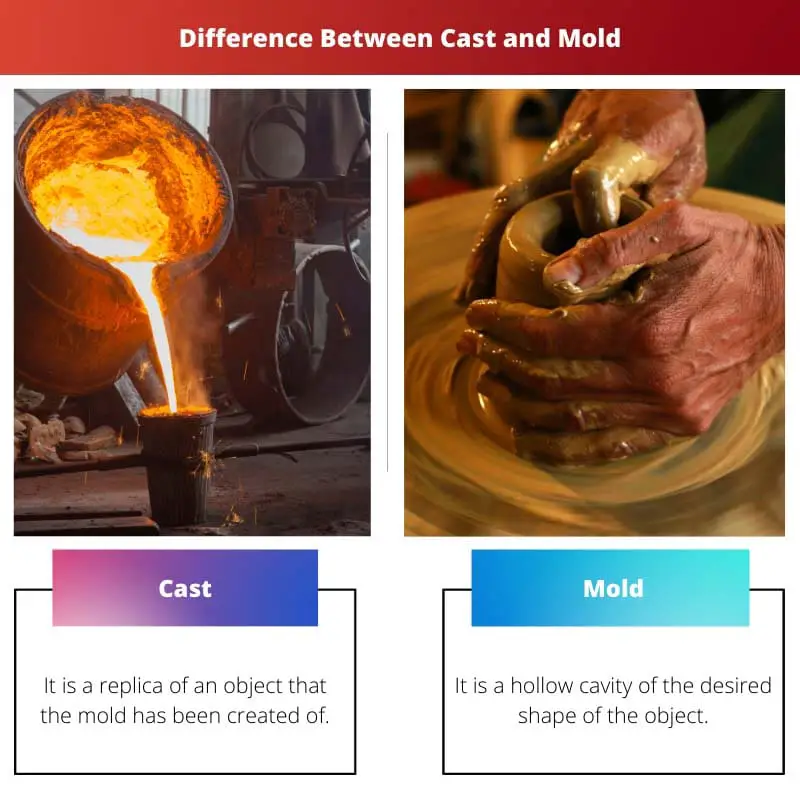

A cast is a reproduction made by pouring a liquid material into a mold, where it solidifies into the desired shape. A mold, on the other hand, is a hollow container used to give shape to the cast material, made from materials like silicone or plaster.

Key Takeaways

- Casting involves pouring molten metal or other material into a mold, and solidifying it into a specific shape or form.

- Molding creates a mold or impression of an object, which can then be used to create a cast or multiple copies of the original object.

- Casting is used to create complex shapes or objects that would be difficult or impossible to produce using other manufacturing techniques. Molding is more commonly used for creating multiple copies of a simple object.

Cast vs. Mold

Cast is the product or shape, or a solid object formed by pouring a mixture into a mold to give it a shape of the mold. Mold is a equipment or a cavity where a liquid mixture is poured to produce a cast. It can be a hollow tool.

A mold is created with certain substances and is left to solidify further. Once it hardens, a casting substance is poured into the hollow cavity to replicate the desired product.

The entire process is known as casting and molding. And the products obtained are cast and molded.

Comparison Table

| Feature | Cast | Mold |

|---|---|---|

| Definition | The final product created by pouring a liquid material into a mold and allowing it to solidify. | The hollow cavity that gives shape to the cast material. |

| Role in Manufacturing | The end product. | The tool used to create the cast. |

| Material | Can be made from various materials like metal, plastic, concrete, etc., depending on the casting process. | Typically made from rigid materials like metal, plastic, or wood, depending on the casting process and desired complexity. |

| Process | Involves melting or mixing a material, pouring it into a mold, and allowing it to solidify. | Involves creating a cavity in the desired shape of the final product. |

| Production of Multiple Copies | Multiple casts can be produced from a single mold, depending on its durability. | A single mold can be used to create multiple casts. |

| Complexity | Can range from simple to complex, depending on the design and casting process. | Can range from simple to highly complex, with intricate details impacting cost and production time. |

| Cost | Cost varies depending on material, size, and complexity of the cast. | Cost depends on material, size, and complexity of the mold, with more intricate designs being more expensive. |

What is Cast?

A cast is a three-dimensional reproduction or replica of an object created by pouring a liquid or molten material into a mold and allowing it to solidify. This process is used across various industries, including manufacturing, art, and dentistry, to produce intricate and accurate replicas of original objects. The cast material can range from metals like aluminum and bronze to plaster, resin, or even concrete, depending on the requirements of the project.

Casting Process

- Preparation: The process begins with the creation of a mold, which is a negative impression or cavity designed to replicate the desired object’s shape. The mold can be made from various materials such as silicone rubber, plaster, or metal, depending on factors like the complexity of the object and the material being cast.

- Pouring: Once the mold is prepared, the liquid or molten material is poured into it. This material can be heated to a specific temperature to ensure proper flow and fill any intricate details of the mold.

- Solidification: After pouring, the material is allowed to cool and solidify within the mold. This can take varying amounts of time depending on the type of material used and its properties. During solidification, the material adopts the shape of the mold, capturing all the details and features of the original object.

- Demolding: Once the material has completely solidified, the mold is removed to reveal the cast object. Care must be taken during this step to ensure that the cast is not damaged or deformed. In some cases, the mold may be reusable for multiple castings, while in others, it may need to be destroyed or altered to remove the cast.

Applications

- Art and Sculpture: Casting is commonly used in art and sculpture to create replicas of original artworks or to produce multiple copies of a sculpture.

- Industrial Manufacturing: In manufacturing, casting is used to mass-produce metal components with complex shapes, such as engine parts, machine components, and decorative elements.

- Dentistry: Dental casts are created to make accurate replicas of patients’ teeth and gums for various dental procedures, including orthodontic treatments and prosthodontics.

- Archaeology and Museums: Casting techniques are employed to replicate archaeological artifacts and museum exhibits, allowing researchers and visitors to study and handle replicas while preserving the originals.

What is Mold?

A mold is a hollow container or cavity used to shape and form materials into specific shapes or designs. In various industries, molds are crucial for creating precise replicas or reproductions of objects. They play a fundamental role in processes such as casting, molding, and forming, enabling the production of items ranging from metal parts to artistic sculptures.

Types of Molds

- Temporary Molds:

- Sand Molds: Used in metal casting, sand molds are made by compacting sand around a pattern, then removing the pattern to leave a cavity.

- Plaster Molds: Commonly used in ceramics and sculpture, plaster molds are created by pouring liquid plaster over a model or pattern, allowing it to harden before removing the original model.

- Rubber Molds: Made from flexible materials like silicone rubber, rubber molds are used in casting resin, wax, or plaster to produce intricate and detailed replicas.

- Permanent Molds:

- Metal Molds: Typically made from steel or aluminum, metal molds are durable and used for high-volume production in processes like injection molding or die casting.

- Graphite Molds: Used in processes such as glassblowing and metal casting, graphite molds withstand high temperatures and are suitable for producing intricate shapes.

Mold Making Process

- Design: The mold-making process begins with designing the mold based on the specifications of the desired object. Factors such as material properties, complexity of the shape, and production volume are considered during the design phase.

- Material Selection: The choice of mold material depends on factors like the casting material, desired surface finish, and production requirements. Common mold materials include silicone rubber, plaster, metal alloys, and epoxy resins.

- Mold Fabrication: The fabrication process varies depending on the type of mold being made. Temporary molds may involve techniques such as sand casting, plaster pouring, or rubber molding, while permanent molds require machining or casting processes to create precise cavity shapes.

- Finishing and Assembly: After the mold components are fabricated, they may require finishing operations such as polishing, sanding, or machining to achieve the desired surface quality. In some cases, multiple mold components are assembled to create complex mold structures.

Applications

- Manufacturing: Molds are extensively used in manufacturing processes such as injection molding, blow molding, and compression molding to produce a wide range of products including plastic components, glassware, and metal parts.

- Art and Craftsmanship: In art and craftsmanship, molds enable the reproduction of sculptures, ceramics, and decorative objects with consistency and accuracy.

- Dental and Medical: Molds are used in dentistry to create impressions of teeth and gums for making crowns, bridges, and dental prosthetics. In the medical field, molds are employed for fabricating custom orthopedic implants and prosthetic devices.

- Food Industry: Molds are utilized in the food industry for shaping and forming various food products such as chocolates, candies, and cheese.

Main Differences Between Cast and Mold

- Purpose:

- Cast: Used to create a final three-dimensional object by pouring a material into a mold and allowing it to solidify.

- Mold: Utilized to give shape to materials by forming a cavity into which the material is poured or pressed, without necessarily producing the final object.

- Output:

- Cast: Produces the final object with the desired shape, texture, and details.

- Mold: Creates a hollow or solid form that serves as a template for shaping materials, but does not constitute the final product itself.

- Process:

- Cast: Involves pouring a liquid or molten material into a mold, allowing it to solidify, and then removing the cast from the mold.

- Mold: Involves creating a cavity or impression in a mold material, into which the material to be shaped is introduced, forming the desired object.

- https://www.sciencedirect.com/science/article/pii/S0924013699003118

- https://pubs.acs.org/doi/abs/10.1021/ja108781w

- https://www.sciencedirect.com/science/article/pii/S1359646204005196

The post raises some intriguing points about the casting and molding processes. It’s apparent that a lot of thought and research went into creating this article.

Absolutely, the detailed information provided highlights the significance of casting and molding in various industries.

I agree, the explanation of the cast and mold is presented in a logical and well-organized manner.

This article offers a comprehensive understanding of casting and molding techniques. The comparison table effectively summarizes the key differences between the two processes.

I agree, the comparison table is a useful reference for distinguishing between cast and mold.

This article is a fascinating read, it sheds light on the intricacies of casting and molding that are overlooked. Well done!

Absolutely, the comparison table further emphasizes the distinctions between cast and mold.

The article provides a clear and concise breakdown of the differences between casting and molding. It’s an excellent resource for anyone wanting to learn more about the topic.

Absolutely, the comparison table is particularly helpful in understanding the distinctions between the two processes.

The comprehensive breakdown of casting and molding processes in this article is indeed commendable. The information shared is valuable and well-articulated.

Absolutely, the detailed comparison of cast and mold is particularly noteworthy. It adds clarity to the topic.

The explanation provided on casting and molding is quite enlightening. It’s a well-researched and informative article. Kudos to the author!

This article provides an in-depth analysis of casting and molding. The comparison table is a valuable resource for understanding the nuances between cast and mold.

I agree, the content is rich with valuable insights into the casting and molding processes.

An insightful and detailed explanation of the casting and molding processes. The information provided is clear and straightforward, making it easy to understand.

I agree, the post provides a comprehensive overview of the topic.

The article offers a meticulous explanation of the cast and mold. It’s evident that the information presented is well-researched and thoughtfully written.

I find the detailed explanation of casting and molding techniques very informative and enlightening.

I agree, understanding the differences between cast and mold is essential in various industries.