When a novice sees a garment, what he sees in a fabric. However, it contains several layers of sewing. Inner fabrics support the outer fabric of a garment.

Different sewing methods bind these garments together. Interlining and interfacing are well-known sewing types. While they may seem identical, interlining and interfacing, vary on several grounds.

Key Takeaways

- Interlining is a layer of fabric inserted between the outer fabric and the lining of a garment to provide additional warmth, structure, or support. At the same time, interfacing is a material used to reinforce specific areas of a garment, such as collars, cuffs, and waistbands.

- Interlining materials can be sewn in, fused, or inserted as a loose layer, depending on the desired effect, whereas interfacing is sewn or fused directly to the fabric.

- Interlining is more common in winter garments, such as coats and jackets, where extra insulation is required. At the same time, interfacing is essential in tailored garments, ensuring crisp edges and maintaining the shape of key elements.

Interlining vs Interfacing

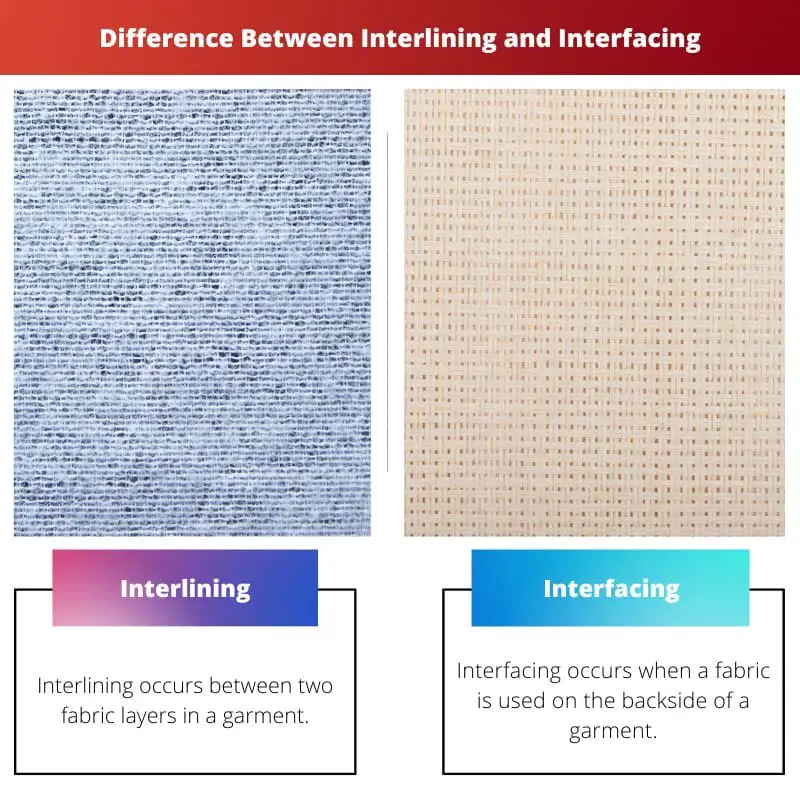

The difference between interlining and interfacing is that interlining is the lining found sandwiched between the outer fabric and the lining of the fabric. On the other hand, interfacing occurs on the backside of the fabric. Interlining can be used in jackets, coats, and vests. In contrast, interfacing can be used in collars and cuffs.

Interlining refers to a fabric used between two layers of fabric. Interlining is not noticeable in a garment because it is carried out in the inner layers.

There are several reasons for interlining garments. The common materials used in interlining are non-woven fabrics and canvas flannel. Dressmakers may choose to add interlinings to the neck or belt of a garment.

Interfacing refers to the fabric used on the unseen side of the garment. While interfacing may be required in some garments, it may not be a necessity in others.

A likely outcome of wrong interfacing is that the garment may become rigid. Interfacing controls and reinforces the shape of the garment.

Comparison Table

| Parameters of Comparison | Interlining | Interfacing |

|---|---|---|

| Definition | Interlining occurs between two fabric layers in a garment. | Interfacing occurs when a fabric is used on the backside of a garment. |

| Application | Interlining has a practical application between the outer fabric and the lining. | Interfacing has a practical application on the wrong side of the garment. |

| Fabric | Interlining is made from non-woven fabrics. | Interfacing is made of both woven and non-woven fabrics. |

| Purpose | The purpose of interlining is to reinforce and support areas of the garment. | The purpose of interfacing is to make the garment stiffer. |

| Examples | Interlining is found in a winter coat. | Interfacing is found in collars and cuffs. |

What is Interlining?

Interlining refers to an accessory used between two layers of fabric. The objective behind interlining garments is to provide them with support and reinforcement, control areas of garments, and maintain the shape and structure of garments.

Interlining may be applied to base fabric either by sewing or by bonding. Finishing is a necessary step in interlining to improve the properties of the garment.

There are two well-known types of interlining: non-fusible interlining and fusible interlining. The advantage of non-fusible interlining is that it is an easy and simple technique for making flame-retardant garments.

It does not require the use of any elaborate machines and can be easily used in highly heated industries. A demerit of non-fusible interlining is that it is not ideal for large-scale production and requires more time.

On the other hand, fusible interlining is easily available in the market. Fusible interlining has high production potential, less fusing time and low labour requirements.

However, the demerits of fusible interlining are that high temperature is a necessity, and special care is a prerequisite for performing attaching interlining.

The process of interlining uses rigid materials such as non-woven fabric and canvas flannel. Interlining can be found in jackets, coats, and vests to make them warmer.

Another reason for interlining garments is to change the drape and shape. However, interlining may not be an ideal option for fabrics that are already bulky. Therefore, interlining has multi-facet applications.

What is Interfacing?

Interfacing is the fabric used on the wrong side of the fabric to make a garment more rigid. There are several reasons for interfacing garments.

For one, interfacing may be used to stiffen or add a body to the fabric. Another reason for interfacing garments is to strengthen a particular part of the garment. For instance, buttonholes and cuffs are interfaced.

Interfacing prevents a garment from stretching out of shape. Interfacing comes in a variety of weights and stiffness to suit various purposes.

Interfacing is also offered in different colours. However, the most common colour offered by interfacing is white. Sometimes, interfacing may make a garment unnecessarily rigid.

The most significant change made to a garment is through the process of interfacing.

Interfacing may also be used to increase the durability of a garment by adding strength to it. Common fabrics used for interfacing are hair canvas, Wigan, and Buckram.

Most of the interfacing fabrics are made from cotton or cotton-polyester blends. Another merit of interfacing is that they are relatively inexpensive.

The popular types of interfacing are fusible interfacing, sew-in interfacing, non-woven interfacing, knit interfacing, and woven interfacing.

There is a specific procedure to be followed to choose the weight of the interfacing fabric. To conclude, interfacing has a wide range of uses today.

Main Differences Between Interlining and Interfacing

- While interlining takes place between two fabric layers of a garment, interfacing occurs on the unseen side of a garment.

- The purpose of interlining is to make a garment warmer. On the other hand, interfacing is done in areas of fabric that need more stability.

- Interlining takes place solely on non-woven fabrics. In contrast, interfacing takes place on both woven and non-woven fabrics.

- The merit of interlining is that it is removable to make the garments more versatile. In contrast, the merit of interfacing is that it offers reinforcement to garments.

- An example of interlining occurs in winter coats and jackets. On the other hand, interfacing may be found in waistbands and buttonholes.

- https://en.wikipedia.org/wiki/Interfacing

- https://www.sciencedirect.com/topics/engineering/interlinings#:~:text=Interlinings%20are%20the%20accessories%20used,From%3A%20Garment%20Manufacturing%20Technology%2C%202015