We consume a large variety of products on an everyday basis to keep our life going. As we are consuming numerous products, it is quite important to check the quality or the standard of the product as the products we are consuming are related to our life which we can’t risk.

The two quality certification, ISO 9000 and QS 9000 shares similar objectives but vary in many parameters.

Key Takeaways

- ISO 9000 is a set of international standards that define quality management systems, while QS 9000 is a quality management system standard used in the automotive industry.

- ISO 9000 focuses on customer satisfaction and continuous improvement, while QS 9000 includes additional requirements like product planning, design, and development.

- ISO 9000 certification applies to various industries, while QS 9000 certification is designed for the automotive industry.

ISO 9000 vs QS 9000

ISO 9000 is a group of international standards for quality management that outlines a quality assurance system for organizations. It focuses on the management of quality, customer satisfaction, etc. QS 9000 is a quality management system that is designed for the automotive industry.

ISO 9000 is a part of the Quality Management Systems (QMS) that sets standards, rules, and regulations for the producers and consumers to maintain in a transaction of buying and selling.

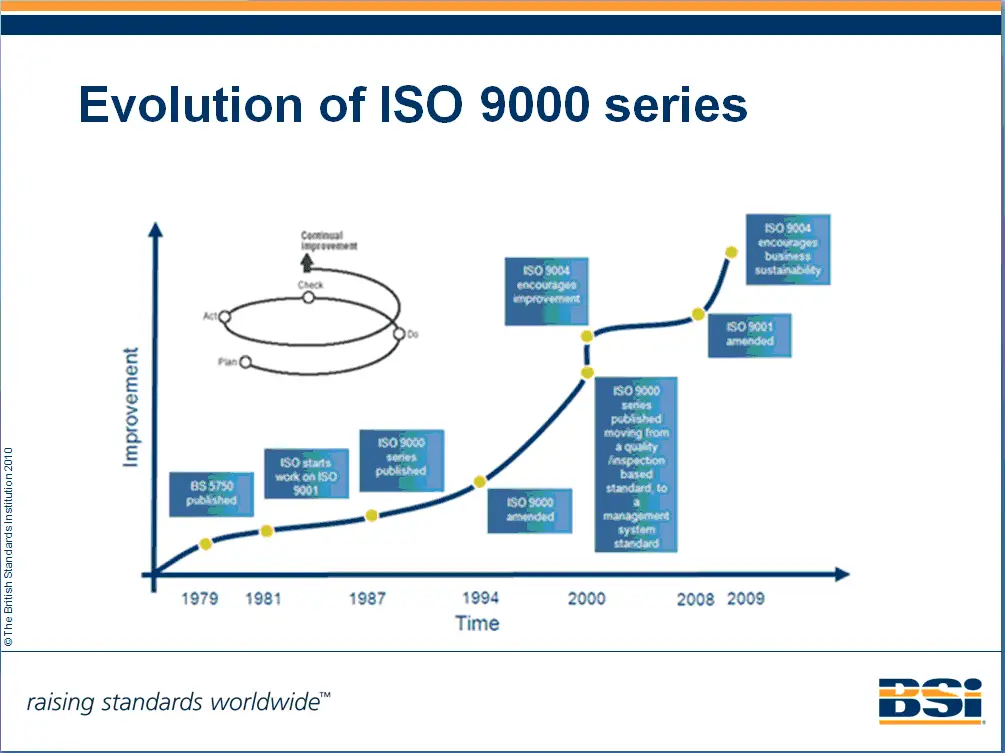

ISO 9000 was first established in 1987 and is considered as the fundamental rule of quality assurance introduced by the Quality Management Systems (QMS).

QS 9000 is also a system built for setting standards and quality levels for the products in the market. QS 9000 was introduced by the joint effort of “Big Three” American automobile manufacturers situated in the United States.

It was first introduced in 1994. This was particularly introduced for automobile industries and truck manufacturers.

Comparison Table

| Parameters of Comparison | ISO 9000 | QS 9000 |

|---|---|---|

| Objective | The objective of ISO 9000 is quality assurance of the product. | The objective of QS 9000 is focused on TQM concepts. |

| Quality levels | ISO 9000 has limited quality levels and does not require high qualities. | QS 9000 has defined high-quality standards that have to be followed. |

| Scope | ISO 9000 is flexible when compared to QS 9000. | QS 9000 is more prescriptive when compared to ISO 9000. |

| Customer satisfaction | ISO 9000 has a limited emphasis on customer satisfaction. | QS 9000 has a high-level determination of customer satisfaction. |

| Improvement | There is limited quality improvement in ISO 9000. | There is continuous quality improvement in QS 9000. |

What is ISO 9000?

ISO 9000 sets rules, regulations, and standards for quality assurance of the products available in the market. It was introduced in 1987 and is a family of Quality Management Systems (QMS).

They introduce standards that require both the stakeholders and consumers to meet in order to complete any type of transaction like buying and selling.

This was created by the International Organization for Standardization (ISO) and they set standards of quality by conducting research and surveys all over the world.

They introduce new policies, improve the existing standards, implement new ideas, plan newer ideas for improving the quality of the products, etc. In short, they are the set of internationally recognized standards for the quality of the products.

The objective of the ISO 9000 is to encourage the producers to produce goods and services of globally acceptable standards and protect the consumers from the exploitations happening in the market.

They issue certificates of product assurance to businesses only when they maintain the guidelines and standards issued by ISO 9000.

Compared to the other schemes of quality assurance, ISO 9000 is flexible and has limited quality levels. Hence, ISO 9000 is a scheme that is beneficial to both consumers and producers all over the world.

What is QS 9000?

QS 9000 also sets rules, regulations, and standards for assuring the quality of the products related to the automobile industry. It was originally developed by the “Big Three” automobile industries.

The “Big Three” means the leading top automobile manufacturers of the United States which are the Daimler Chrysler Corporation, Ford Motor Company, and General Motors Corporation.

QS 9000 issues a set of standards that have to be followed by the automobile industries who supplied and produced parts of the automobiles. The standard is divided into three sections.

The first section includes the standards and rules that were issued by the ISO 9000 and includes some other quality requirements of automotive.

The second section includes some other additional requirements related to the truck requirements and other automotive. The third section emphasizes customer satisfaction that is titled a customer-specific section.

QS 9000 concentrates on various TQM concepts and has continuous quality improvement. They have well-defined quality levels and standards.

Compared to other schemes implemented for quality assurance, QS 9000 is less flexible and more prescriptive. They focus on maximum customer satisfaction. QS 9000 enhances the quality systems of automobiles for suppliers.

They eliminate the wastes involved in manufacturing automobiles and result in reducing costs.

Main Differences Between ISO 9000 and QS 9000

- ISO 9000 was introduced in 1987 and is a part of QMS while QS 9000 was introduced in 1994 by the “Big Three” automobile industries.

- ISO 9000 focuses on the quality of the products while QS 9000 focuses on the quality of the automobile products.

- ISO 9000 has limited sets of standards for quality assurance while QS 9000 has well-defined quality standards.

- The improvement of quality in the products is limited in ISO 9000 while QS 9000 has continuous quality improvement in the products.

- ISO 9000 sets standards that are more flexible while standards set by QS 9000 are less flexible and restricted.

- https://www.emerald.com/insight/content/doi/10.1108/02656710110407127/full/html

- https://www.emerald.com/insight/content/doi/10.1108/09544780110401871/full/html