Grease is a solid or semi-solid lubricating oil that is created as a hardening ingredient dispersed in a fluid lubricant. Greases are used to hydrate devices that can only be oiled seldom and where lubricating oil would not remain in place.

People frequently mix up the two most common ones dielectric grease and silicone grease, with a few mistaking one for the other.

Key Takeaways

- Dielectric grease is an insulating grease, while silicone grease can be insulating and conductive.

- Dielectric grease is primarily used to protect electrical connections, whereas silicone grease has a wider range of applications.

- Both greases are water-resistant and thermally stable but have different consistencies and performance characteristics.

Dielectric Grease vs Silicone Grease

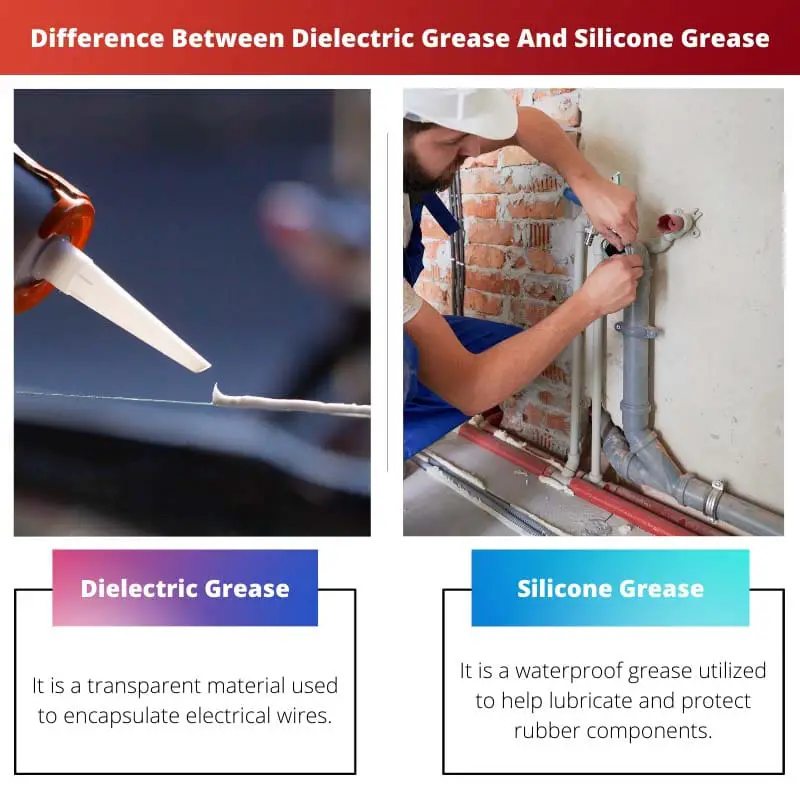

The difference between Dielectric grease and Silicone grease is that dielectric grease is a translucent material that can be used to encapsulate electrical wires. Silicone grease, on the other hand, is a waterproof grease made by mixing silicone oils.

Dielectric grease, sometimes known as tune-up grease is a sticky non-conductive material that is used to safeguard electrical contacts from deterioration and dust. It is composed of a silicone base and a thickener.

Its hue is a somewhat transparent grey or milky clear. When applied sparingly on components such as spark plug boots, trailer connections, battery terminals, bulb sockets, and so on, dielectric grease functions as a lubricant, sealer, insulator, and protectant.

Silicone grease is a waterproof grease made by mixing silicone oils and a thickener. It is electrically insulating, and they are frequently used to cover and protect power cables, especially those with rubber seals.

In special forms, silicone grease is also frequently employed in the plumber’s sector in nozzles, sealing, and dental products. These unique variants are made using ingredients that are not considered to pose an ingestion risk.

Comparison Table

| Parameters of Comparison | Dielectric Grease | Silicone Grease |

|---|---|---|

| Meaning | It is a transparent material used to encapsulate electrical wires | It is a waterproof grease utilized to help lubricate and protect rubber components |

| Characteristics of chemicals | It continues to be accessible and does not heal | Cures to a hard state |

| Utilization | It is utilized whenever power supplies, such as cables or terminals, come into direct contact with moisture. | It is utilized mostly as a temporary sealant as well as a lubricant to join grounded glass junctions and to seal and preserve O-rings |

| Thickness | Dielectric grease is less thick | Silicone grease is thicker in comparison |

| Expense | Dielectric grease is expensive | Silicone grease is relatively cheap |

What is Dielectric Grease?

Dielectric grease is a lubricant used to encapsulate electrical conductors to keep dust, moisture, mud, and other foreign elements from adhering to the conductor. It also stops the conductor from moving electricity between both contact points.

Dielectric grease differs from ordinary grease in several ways, including its physical characteristics and application. When utilized in elevated situations, most ordinary grease weakens and dissolves.

This is due to the fact that they are produced with low melting points. Dielectric grease, but on the other hand, has high thermal conductivity and may be utilized on materials that are subjected to high temperatures.

Furthermore, the dielectric grease serves as protection by blocking moisture. Because the grease is transparent, some light penetrates it, creating distortion.

It has a greyish look. The primary application of dielectric grease is lubrication, insulating, and shielding equipment from elements of nature and alien substances.

When dielectric grease is added to metal components of a power system, it prevents corrosion and deterioration. Because this oil can endure high temperatures, it will keep the sealing intact up to 500 degrees Fahrenheit.

It also protects plastic and rubber in electrical computers and electronic chips against fire as well as other disasters. Dielectric grease extends the life of connecting and linking surfaces by reducing wear.

As a result, the interconnecting surfaces create a multilayer layer that reduces tolerance and avoids oxidation.

What is Silicone Grease?

Silicone grease is waterproof that is made from silicone oil and inert additives enhanced with lithium. Silicone grease prepared by this technique is a translucent white viscous paste, the specific characteristics of which depend on the kind and quantity of the constituents.

Silicone grease is utilized grease and protects multiple kinds of rubber seals, such as O-rings, without stretching or loosening them. On non-metal-metal contact areas, it works effectively as corrosion protection and lubrication.

In the plumber’s sector, pure silicone grease is commonly utilized in taps and sealing and in medical products. This is owing to the fact that it is not a choking danger. Power companies use silicone grease to removable oil joints in cables subjected to extreme temperatures

Silicone grease is extensively used in various high-voltage interconnections with gasoline fuel injectors, where grease is applied to the elastic boot of the outlet wiring to assist it in sliding above the porcelain insulator, secure the rubber boots, and prevent the rubber from sticking to the porcelain. These greases are made to withstand the extreme temperature that is prevalent in areas where products of combustion are placed.

Silicone grease can break down to produce a layer of insulation at or near the arcing circuit, and infection can cause the connections to fail abruptly.

Main Differences Between Dielectric Grease And Silicone Grease

- Dielectric grease is a transparent liquid that is used to coat electrical conductors and shield them from sand, dirt, mud, and other foreign influences that may adhere to the conductor. Whereas, Silicone grease is a waterproof grease made by mixing silicone oils with thickening and is used as a lubricator and maintains rubber parts.

- The primary application of dielectric grease is lubrication, shielding, and insulation of hardware from elements of nature and alien substances. On the other hand, silicone grease is primarily used in factories, and chemical labs, as a temporary sealant, for lubricating pen-filling threads, greasing shower heads, door hinges, and so on.

- Dielectric grease is highly expensive because of the structure of its applications. However, silicone grease is quite inexpensive.

- Dielectric grease remains flexible, whereas silicone grease dries to a solid shape.

- Dielectric grease is relatively thinner, whereas silicone grease is thicker.

- https://ieeexplore.ieee.org/abstract/document/4451484/

- https://onlinelibrary.wiley.com/doi/abs/10.1002/app.12363

Last Updated : 11 June, 2023

Piyush Yadav has spent the past 25 years working as a physicist in the local community. He is a physicist passionate about making science more accessible to our readers. He holds a BSc in Natural Sciences and Post Graduate Diploma in Environmental Science. You can read more about him on his bio page.

I found the in-depth exploration of dielectric grease and silicone grease to be very enlightening. The information on their properties and applications is presented in a highly engaging and informative manner.

I found the explanation of the uses and properties of dielectric grease and silicone grease to be very educational. It’s a well-researched piece that sheds light on the importance of these greases in various industries.

I appreciate the detailed explanation of the differences between dielectric grease and silicone grease. It’s fascinating to learn about the various applications of these two types of greases in different industries.

Absolutely, the comparison table also makes it easier to understand the distinctions between dielectric grease and silicone grease. Very insightful.

I couldn’t agree more. The article provides a comprehensive overview of the characteristics and applications of both types of grease. It’s informative and well-written.

The article provides a thorough examination of the differences between dielectric grease and silicone grease. The information on the distinct applications and chemical characteristics is highly informative.

The detailed comparison between dielectric grease and silicone grease is enlightening. It’s great to learn about the specific uses and characteristics of each type of grease.

The article offers a detailed analysis of dielectric grease and silicone grease, outlining their specific functions and chemical compositions. It’s a valuable resource for anyone looking to understand these types of lubricating greases.

The comparison table provides a clear and concise summary of the differences between dielectric grease and silicone grease. It’s a well-structured article that presents complex information in an accessible way.

The detailed examination of dielectric grease and silicone grease is both informative and engaging. The article effectively communicates the distinctions between the two types of grease and their respective uses.