We utilize a lot of printed stuff these days. The printing method for these materials changes between offset and digital printing. Offset and digital printing are both effective technologies.

Depending on the needs of your project, each offers distinct advantages. It is critical to distinguish between the two in order to make an informed decision for your product requirements.

Key Takeaways

- Offset printing uses plates and ink rollers to transfer images onto paper, while digital printing directly prints images using inkjet or laser technology.

- Offset printing offers higher-quality images and consistent color reproduction, but digital printing allows for faster turnaround and lower costs for small print runs.

- Offset printing is more cost-effective for large quantities, while digital printing is better suited for short runs and personalized printing.

Offset Printing vs Digital Printing

Offset printing transfers an inked image onto a rubber sheet, which subsequently prints onto the paper, enabling for high-quality, high-volume output. Digital printing uses digital files and a toner or inkjet printer to print directly onto the paper, making it more cost-effective for small runs.

The offset printing method uses metal plates to transmit an impression onto a rubber “blanket” before rolling that impression onto a piece of paper.

Since the ink is not deposited directly onto the paper, it is referred to as offset printing. Offset printing is the greatest option when huge numbers are required since offset presses work effectively once set up.

Digital printing is a way of printing straight from a digital photo to a variety of surfaces. It is more expensive per page. It, unlike printing technology, does not require plates but rather a toner (as in laser printers) or bigger printers that do use liquid ink.

Comparison Table

| Parameters of Comparison | Offset Printing | Digital Printing |

|---|---|---|

| Sheet Size | Prints larger sheet sizes- 29” to 40” | Prints smaller sheet sizes- 19” to 29” |

| Speed of Printing | The speed of printing is slower | The speed of printing is quicker |

| Process | Metal plates are used to apply ink to the surface | Electrostatic rollers are used to apply ink to the paper |

| Color Control | It provides more color control while printing | It provides less color control while printing |

| Quality | It provides higher printing quality | It provides a lower quality printing |

What is Offset Printing?

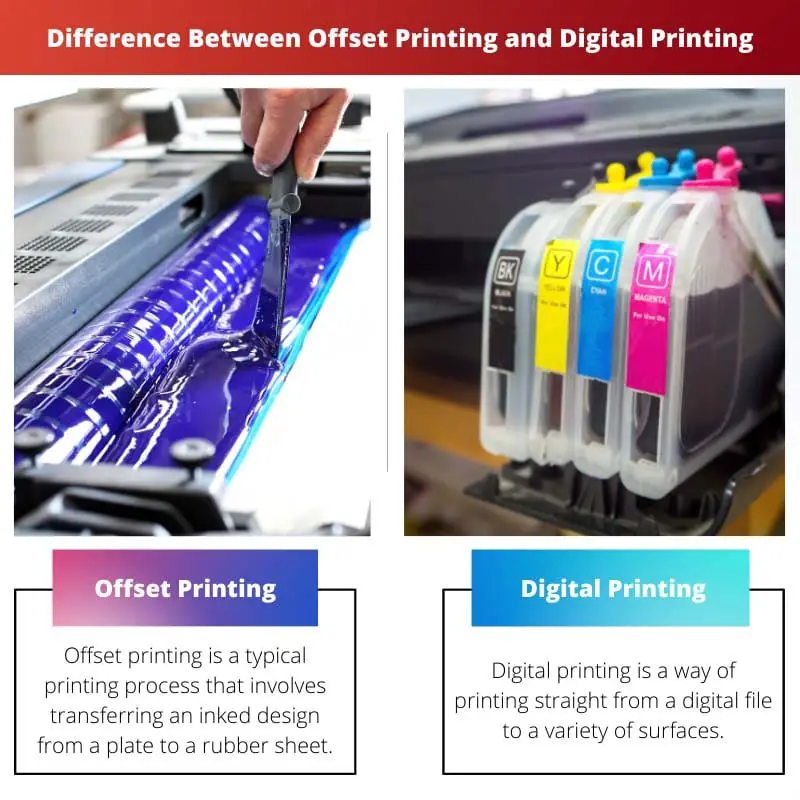

Offset printing is a typical printing process that involves transferring an inked design from a plate to a rubber sheet and subsequently to the printed page.

The offset approach utilizes a flat (planographic) pattern carrier when employed in conjunction with the lithographic process.

Ink rollers apply ink to the image carrier’s image portions, whereas water rollers apply a water-based coating to the non-image parts.

The current “web” technique feeds a big reel of paper in sections, for several meters, through a massive press machine, which further prints constantly as the material is fed through.

Offset printing is classified into two types: wet offset and waterless offset. Waterless offset lithography uses a distinct process in which an ink-repellent silicon layer shields the non-image portions of a plate.

Simultaneously, offset printing has produced the finest quality attainable on the biggest range of papers and gives the greatest degree of color control.

Furthermore, offset printing is the most cost-effective option when generating a large number of reproductions from a few originals.

Offset printing tends to produce sharper and cleaner images and categories than some other printing processes since the rubber grip conforms to the sharpness of the printed page; quick and simple printing plate production; and extended printing plate longevity than traditional litho presses due to the lack of tight interface between the plates and the printing surface.

What is Digital Printing?

Digital printing is a way of printing straight from a digital file to a variety of surfaces. Small-run projects from digital design and other sources available are produced using massive formats and/or high-volume lasers or inkjet cartridges.

Digital printing is more expensive per page than conventional offset printing processes, however, this expense is compensated by reducing the cost of all the technical stages necessary to create printing plates.

It also enables on-demand printing, quick turnaround times, and even picture change (variable data) for every imprint.

Due to various manpower reductions and electronic presses’ ever-increasing capabilities, digital printing is on its way to matching or surpassing offset printing technology’s capacity to generate massive print runs of several thousand sheets at a cheap cost.

There are several advantages to using digital printing over older techniques.

Some notable applications include extremely cheap domestic and office publishing is only possible due to digital mechanisms that eliminate the need for plates; data system print files are being used for bulk customization of hard copies.

Digital printing is used for personalized printing, such as kids’ literature personalized with children’s names, photo albums (such as wedding photo books), and other books.

Digital printing is the most efficient method for producing short runs, especially when there are a lot of originals.

Main Differences Between Offset Printing and Digital Printing

- Offset printing produces bigger sheet sizes ranging from 29″ to 40″, whilst digital printing produces smaller sheet sizes ranging from 19″ to 29″.

- Offset printing is slower in comparison to digital printing, which is faster.

- In offset printing, metal plates are used to apply ink to the surface, meanwhile in digital printing, electrostatic rollers are used to apply ink to the paper.

- Offset printing allows for greater color control during printing, whereas digital printing allows for less color control while printing.

- Offset printing produces higher-quality prints, whereas digital printing produces lower-quality prints.

The article presents a comprehensive comparison between offset printing and digital printing, shedding light on their unique advantages and best use cases.

I agree, the thorough breakdown of processes and the discussion of quality differences provide valuable insights for those considering these printing methods for their projects.

I find the part about offset printing being more cost-effective for large quantities and digital printing being better suited for short runs and personalized printing to be quite intriguing.

I greatly appreciate the detailed explanation of both offset and digital printing; it’s essential to understand and recognize the differences based on project requirements. Thanks for the insightful article!

This is a well-rounded article, offering balanced arguments and thorough explanations. I now understand the reasoning behind the preference for either method.

This comparison table is quite helpful in determining which method is most suitable for a particular project, especially when factoring in variables such as cost and speed.

I think offset printing represents a high-value item in the industry that provides endless possibilities for optimizing product cost and time.

The precision achieved through offset printing is impressive, but the faster turnaround and lower costs of digital printing make it an appealing option as well.

While digital printing might be faster, it seems that offset printing provides a superior product quality, which is more important for a lot of projects.