Thermoplastics refer to the polymers that can be melted and recast. They melt when heated, harden when cooled, and turn glass-like when frozen.

They are utilized in daily activities and which is why they are important. Every thermoplastic has a different production method and properties.

Pla and Abs are two very popular thermoplastics.

Key Takeaways

- PLA is a biodegradable plastic derived from renewable resources, such as cornstarch, making it eco-friendly.

- ABS is a petroleum-based plastic known for its strength, durability, and resistance to heat.

- PLA is easier to print within 3D printing, while ABS requires higher temperatures and a heated bed.

PLA vs ABS

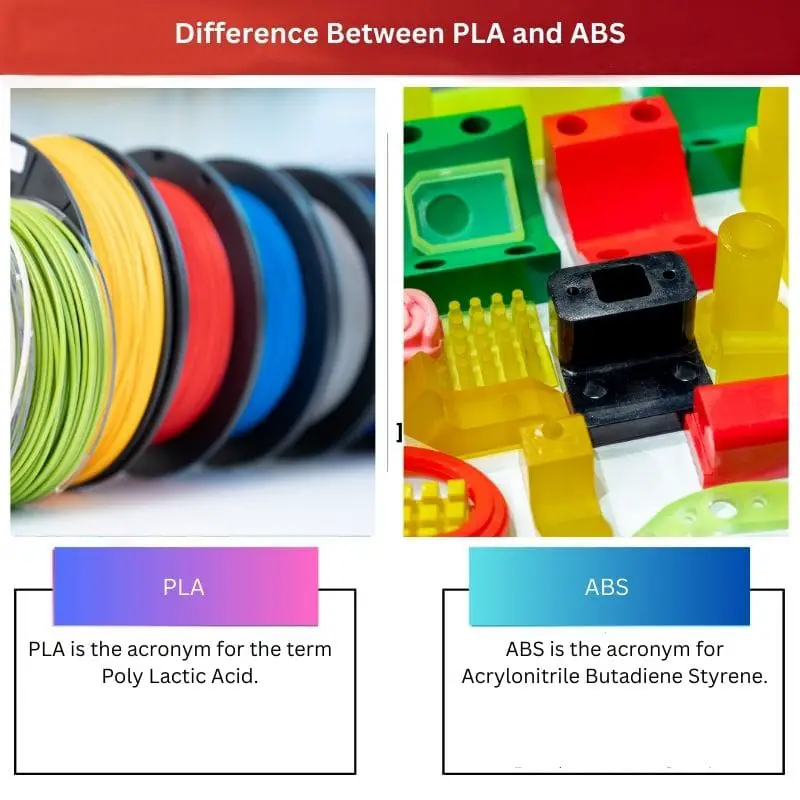

PLA is an acronym that stands for Poly Lactic Acid and is a thermoplastic polymer that is extracted from organic and renewable resources, and it is biodegradable. ABS stands for acrylonitrile butadiene styrene, and it is a thermoplastic polymer gotten from butadiene, acrylonitrile, and styrene.

PLA stands for Poly Lactic Acid, which is a thermoplastic polymer. It is popularly used in 3D printing as a plastic filament.

It is biodegradable as it is plant-based. It is also water-soluble.

This polymer is made from the Lactic Acid monomer. This thermoplastic has a low melting point.

ABS stands for Acrylonitrile Butadiene Styrene, which is also a thermoplastic polymer. This, too, is popularly used in 3D printing.

It is petroleum-based and is not biodegradable. It is made from acrylonitrile, butadiene, and styrene monomers.

It has no specific melting point. It is also less durable and flexible.

Comparison Table

| Parameters of Comparison | PLA | ABS |

|---|---|---|

| Full Form | PLA is the acronym for the term Poly Lactic Acid. | ABS is the acronym for Acrylonitrile Butadiene Styrene. |

| Monomers | It is made from the Lactic Acid monomer. | It is made from acrylonitrile, butadiene, and styrene monomers. |

| Polymer | It is an aliphatic, thermoplastic polymer. | It is an amorphous, thermoplastic polymer. |

| Base | This thermoplastic polymer is water soluble and corn-based. | This thermoplastic polymer is petroleum based. |

| Utilization | This is ideally utilized for support material. | This is ideally utilized for injection moulding. |

| Environment friendly | It is environmentally friendly as it is non-petrochemical plastic. | Due to its oil-based plastic combination, it is not environmentally friendly. |

| Durability | It is more durable. | It is less durable. |

| Melting point | It has a lower melting point. | It has no exact melting point. |

| Flexibility | It is more flexible. | It is less flexible. |

What is PLA?

PLA or Poly Lactic Acid refers to a thermoplastic polymer made from renewable and organic resources, which is also biodegradable. This is made from fermented plant starch.

The plant starch can be derived from corn, maize, sugarcane, or sugar beet pulp. With the help of the fermentation process, the sugar in them is turned into la.

The sugar in these renewable materials is fermented and turned into lactic acid. It is then turned to polylactic acid.

Pla properties make it useful for a wide variety of purposes. It is used in manufacturing plastic films and bottles.

It is also used for making biodegradable medical objects. It is widely utilized in 3D printing as plastic filaments.

However, due to a low melting point, it is not used in objects made to hold hot fluids. Energy used for producing Pla is 65% less than other plastic production.

The greenhouse gases generated during the process are also 68% less than others. These gases do not contain any toxins.

If recycling, composting, incineration, or landfilling methods are adopted, they can be environmentally friendly. The degradation process takes a long time.

The process of degradation can be carried out with the help of hydrolysis, thermal degradation, or photodegradation.

What is ABS?

ABS or Acrylonitrile butadiene styrene refers to a thermoplastic polymer. This is made up of three acrylonitrile, butadiene, and styrene monomers.

It is petroleum-based and is not eco-friendly. The emulsion or continuous mass technique is used for the production of ABS.

In its original state, the material has an opaque ivory color. This is later painted or dyed.

The polar solvents can easily attack ABS. This is utilized for injection moulding applications.

It is popularly used in 3D printing. The production of this type of plastic costs more and is also easy to produce.

This also has a wide range of material properties. Some of these include rigidity, weldability, impact and chemical resistance, abrasion, stiffness, strength, temperature performance, and electric insulation.

It is also readily modified. This can be done by the addition of additives and variation in the ratios of monomers.

The initial creation process helps in acquiring these physical attributes. The powerful combination of resources provides hardness, toughness, resistance, and a glossy look.

The material properties of this plastic have their advantages and disadvantages. The disadvantages include sunlight damage, and solvent resistance, which can be harmful if burned, cannot always be used in food material packaging, and are costly in comparison with polystyrene.

Main Differences Between PLA and ABS

- PLA is the acronym for the term Poly Lactic Acid. ABS is the acronym for Acrylonitrile Butadiene Styrene.

- PLA is made from the Lactic Acid monomer. ABS is made from acrylonitrile, butadiene, and styrene monomers.

- PLA is an aliphatic, thermoplastic polymer. ABS is an amorphous, thermoplastic polymer.

- PLA- thermoplastic polymer is water-soluble and corn-based. ABS- thermoplastic polymer is petroleum-based.

- PLA is ideally utilized for support material. ABS is ideally utilized for injection moulding.

- PLA is environmentally friendly as it is non-petrochemical plastic. Due to its oil-based plastic combination, ABS is not environmentally friendly.

- PLA is more durable. ABS is less durable.

- PLA has a lower melting point. ABS has no exact melting point.

- PLA is more flexible. ABS is less flexible.

PLA and ABS are two very important and popular thermoplastics. ABS is a petroleum-based plastic, while PLA is derived from renewable resources and is eco-friendly.

The comparison table clearly outlines the differences between PLA and ABS. It’s interesting to note that PLA is more environmentally friendly and has a lower melting point than ABS.

I found it very informative to learn about the production methods and properties of PLA and ABS. The fact that PLA is more durable and environmentally friendly makes it a compelling choice.