Plywood and Board are the two wood-engineered items used for crafting interiors and furniture. It is impossible to assume a house or office without furniture and furniture are made up of Plywood and Board which are produced by different trees.

In our everyday life, we use them in our surroundings. Both of them have different usage and unique properties as detailed further:

Key Takeaways

- Plywood is an engineered wood product made by glueing together thin layers of wood veneer, while boards are flat, elongated pieces of solid wood.

- Plywood offers better strength and stability than boards due to its cross-grained structure.

- Boards are more suitable for aesthetic purposes and woodworking projects, while plywood is commonly used in construction and furniture making.

Plywood vs Board

Plywood is an engineered wood product made by gluing together thin layers of wood veneer with each layer’s grain direction perpendicular to the previous layer. Board, also known as particleboard, is an engineered wood product made by compressing wood particles or fibers together with adhesives.

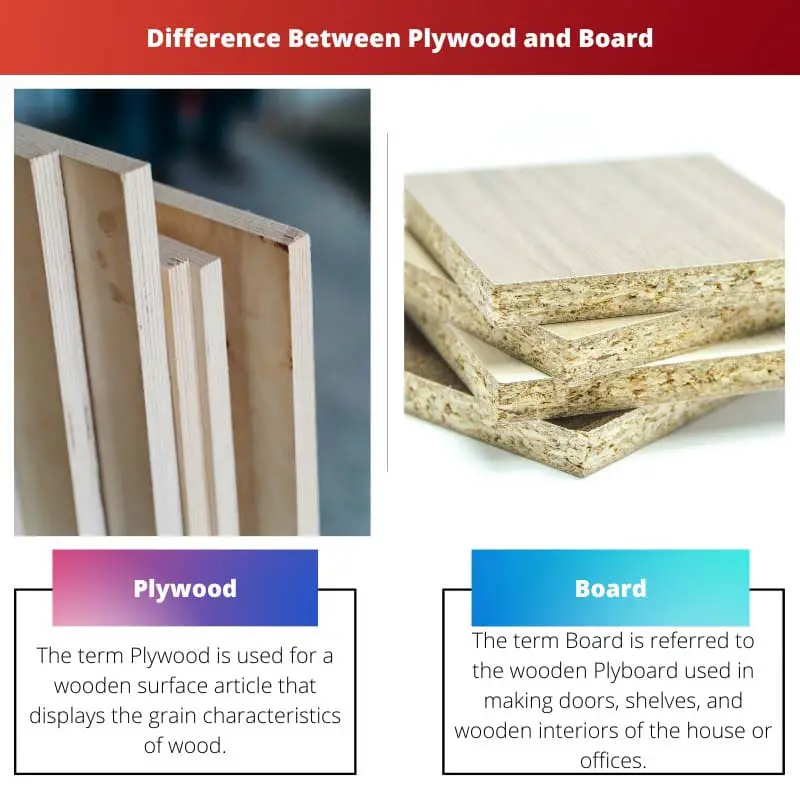

The term Plywood is used for a wooden surface article that displays the grain characteristics of wood. It can be easily laminated with a lacquered sheet, painted, or veneered.

The edges of the plyboard are visible as thin wooden layers glued together. It is used in the making of wooden furniture mostly that does not require a big plyboard.

The term Board is referred to the wooden Plyboard used in making doors, shelves, and wooden interiors of the house or offices. It is crafted using various surfaces such as melamine, laminated or plastic sheets, etc.

The strength of the Board is weaker as compared to plywood. It is not susceptible to bending due to its hardness.

Comparison Table

| Parameters of Comparison | Plywood | Board |

|---|---|---|

| Moisture Effect | It resists moisture and protects the furniture. | It retains moisture and damages the furniture. |

| Efficiency | Plywood can be easily bent from the center. | The Board on the other end, Is very hard and cannot be bent easily. |

| Risk | Plywood has no risk of water damage. | Board has the risk of water damage as no protection shield is available. |

| Strength | The Plywood is less strong in comparison to the Board. | Board is stiff and tough in comparison to Plywood. |

| Cutting | Plywood cannot be easily cut as there is a risk of a splinter. | Board can be easily cut with the traditional wooden tools as there is no risk of a splinter. |

What is Plywood?

Plywood is the wooden material created with piles of thin wood sheets for crafting small wooden items and furniture.

It is a good option for making office cabinets and kitchen cabinets as these cabinets are hung up on walls and the Plywood is lighter in weight.

A slight advantage of Plywood is superior tensile and shearing properties that are not available with any other kind of wood. It is very much resistant to scratches and dents.

One can easily sag or bend the plywood which creates a splinter. The cutting of plywood is a very crucial task to be performed.

Following are the main items crafted with the help of Plywood are floors, roofs, TV units, fences, cabinets, boats, and ships. It is not compatible with big-size doors, books shelves, beddings, etc. due to its flexible molecules.

By laminating the plywood one can increase its shelf life by 15-20 years as it does not swell in sticky climate.

The maximum thickness range of Plywood is 25mm. It can bend from the center very easily. Fewer chances of damage occur while we screw or hammer in plywood due to its rough texture.

Since it is very easy to maintain therefore interior designers prefer it, Though it is an expensive option for furniture and interiors

What is Board?

Board is very prominent terminology used in various ways but here we are explaining about the wooden Plyboard. It is made up of wood planks combined with thin wooden sheets over it.

It is a budget-friendly wooden material used for giant wood items like walls, doors, tables, counter-top, etc. It can swell up easily in high moisture conditions.

Molding, Bending, and shaping are quite tough in the case of the board. The maximum thickness range of the Board is a maximum of 28mm which is similar to Plywood.

It has a very short life span with high efforts on maintenance. The surface of the Board does not display a grains pattern instead of this it is manufactured with different supportive coverings like Melamine, lamination or plastic sheets, etc.

The wooden blocks of the board have tiny gaps between them which can only be seen with a magnifier glass. It is highly resistant to cracking and wrapping. The board is soft inside and hard from outside.

The wooden effect is very solid in the case of Board which is missing in Plywood. The Board uses Plywood in its making whereas no use of Board in making of Plywood. Painting and Polishing is the way to protect it for a long duration.

Main Differences Between Plywood and Board

- Structure: Plywood has uniformity in its length and breadth on the flip side Board has different shapes and structures with small gaps in it.

- Appearance: Plywood appears as sheets of wood glued together whereas Board appears as a solid wooden piece of plank from the edges.

- Weight: Plywood is lighter than the board in weight and Board is heavier since it is made up of thick wooden blocks.

- Measurement: The standard thickness of Plywood is 3mm and 25mm whereas the standard thickness of Board is 16mm and 28mm.

- Cost: Plywood is expensive as compared to Board because it is used for the final look of interiors or wooden items.