In the contemporary world, several vehicles are roaming on the roads to carry people or goods. The tires play an important role in each vehicle.

They are ring-shaped components and surround a wheel’s rim. With the improvement in technology, more wheels were also developed and updated.

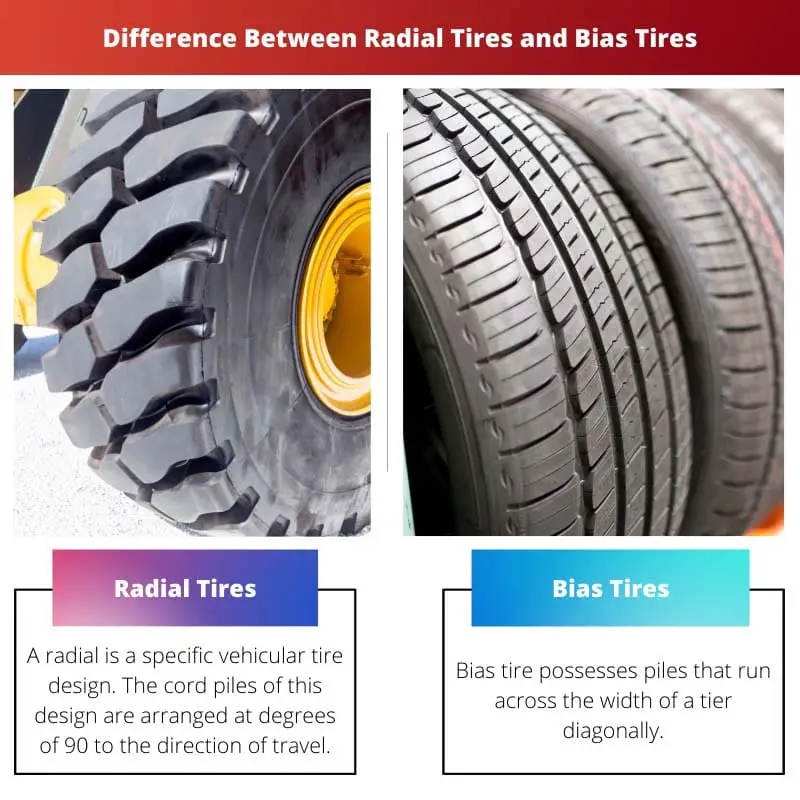

When it’s time to choose the right tire for a vehicle, then needs more matter than size. In the market, there are different tires with different construction available. Radial tires and bias tires are two of the tires with several distinctions.

Key Takeaways

- Radial tires have ply cords that run perpendicular to the tread, while bias tires have cords that run at a 45-degree angle.

- Radial tires have better traction, fuel efficiency, and durability than bias tires.

- Bias tires are cheaper and better suited for heavy-duty applications than radial tires.

Radial Tires vs Bias Tires

Radial Tires are a particular type of vehicle tires that were made by Arthur William Savage in 1956, and it is used mainly for a car taken to embark on long trips. Bias tires are a specific kind of tire that was made by The Michelin Brothers in 1969, and they have diagonal piles.

There is a rubber-coated steel belts layer on the outside casing of the radial tire. This layer consisted of rubber-coated steel inserted into the rubber, known as piles. The piles run radially and start at the center.

This design of tire is also known as a cross-ply tire. The main cords or piles of bias tires run across the bead. The piles run at 45 degrees to the tread centerline. A small tire can carry more weight compared to a similar size of radial time.

Comparison Table

| Parameters of Comparison | Radial Tires | Bias Tires |

|---|---|---|

| Origin | In 1956 | In 1969 |

| Inventor | Arthur William Savage | The Michelin Brothers |

| Usage | Regular | Infrequent |

| Trips | Long trips | Short trips |

| Contact with ground | More | Less |

What are Radial Tires?

A radial is a specific vehicular tire design. The cord piles of this design are arranged at degrees of 90 to the direction of travel.

In North America, the construction market share of this tire climbed to 100%. The consumer’s report found the superiority of this design in 1968.

The steel wires in tiers become magnetized with the usage, and an alternating magnetic field is created as they rotate. With the help of an EMF meter, it is quite measurable which is close to the wheel by its rotation.

These tire designs are ideal for sports vehicles and also for vehicles with extremely rigid chassis.

The radial tire tread does a better job of road-gripping and also provides improved maneuverability and durability.

They are more flexible and gives a more comfortable ride due to their pile’s movement radially instead of diagonally from bead to bead around the tire. In terms of high speeds, for more powerful vehicles, radial tires become necessary.

Radial tires provide a thick shoulder to protect the interior from damage and shocks. Less fuel is used on radial tires due to rolling resistance. Because this tire generates less heat, it lasts longer. They also provide less vibration and more stability.

What are Bias Tires?

Bias tire possesses piles that run across the width of a tier diagonally. Underneath the sidewall and tread, these diagonal piles crisscross and run from bead to bead. These piles run between the angles of 30 and 40 degrees.

The advantage of using this tire is to ride comfortably. Bias tires can tackle roads with rough texture without sacrificing ride comfort. But the rolling resistance is diminished because of the construction of an angled ply.

The cord of these tires is made of synthetic fabrics like polyether. It is more resistant to cuts and impacts. When this tire runs on a rough road, its carcass demonstrates endurance and strength.

Ride comfort was of more concern compared to rolling resistance when this tire was developed. People preferred only short distances.

The environmental concern was not widespread as a result, at that time, fuel was cheap. Later, the perfection and development of radial tires surpass the performance capability of this tire.

But still, bias tires in the contemporary world are manufactured and used on several tractors or heavy machinery.

Some of the drawbacks of bias tires are weak grip, large weight, shortened operational lifetime, low wear resistance, lower load-carrying capacity, difficult car handling, and the carcass made of synthetic materials.

Main Differences Between Radial Tires and Bias Tires

- Radial tires are made by crisscrossing steel belts beneath the tread. On the flip side, bias tires are constructed with crisscrossing cords of nylon and polyester belts.

- With the tread line, the steel belts of radial tires run at a 90-degree angle. But the nylon belts of bias tires run at an angle of 30 to 45 degrees with the tread line.

- Radial tires are ideal for sports vehicles and also for vehicles with extremely rigid chassis, whereas bias tires are ideal for small or medium-sized engine vehicles that move at moderate speeds.

- When it comes to high speeds, for more powerful vehicles, radial tires become necessary. But high-speed bias tires have poor traction and are more prone to fuel consumption and overheating.

- The tread and sidewall of the radial tire function independently, whereas due to multiple overlapping rubber piles in bias tires, they connect the tread and sidewall.

- https://meridian.allenpress.com/rct/article-abstract/54/3/461/91364

- https://www.sae.org/publications/technical-papers/content/690522/

The article effectively highlights the key takeaways of radial tires versus bias tires. The comparison table provides a concise view of the differences in origin, usage, and contact with the ground. It’s fascinating to learn about the historical background of these tire types.

The article provides a comprehensive overview of the differences between radial and bias tires. The information is clearly presented with a good level of detail. It’s an enlightening read for automotive enthusiasts.