Processor Sizes

When discussing processors, you may come across terms like 5nm, 7nm, 10nm, and 14nm. These numbers represent the processor size, specifically the distance between transistors on a chip. Smaller sizes, like 5nm, result in higher transistor densities, offering improved performance and energy efficiency.

As chip manufacturers continue to innovate, the nanometer (nm) measurement has become critical for comparing different processor technologies. A smaller nm value corresponds to a more advanced manufacturing process, leading to more powerful and efficient processors.

Here are some key points to remember when understanding processor sizes:

- Performance: Smaller-sized transistors can switch faster, improving overall performance.

- Power efficiency: A higher transistor density lowers power consumption, providing better device battery life.

- Heat management: Smaller-size processes generate less heat, ensuring better thermal management.

However, achieving smaller transistor sizes is limited due to physical and technical constraints. As the industry pushes toward even smaller sizes in search of better performance and efficiency, new challenges in semiconductor design arise. It’s essential to balance power, performance, and cost to provide the best overall experience for users.

Significance of Nanometers (nm) in Processors

Nanometers (nm) play a crucial role in the manufacturing of processors. The nm value represents the size of the transistor’s smallest feature. Smaller nm values translate to smaller, more efficient, and faster processors.

Energy efficiency: The smaller the transistor, the less power it consumes. You’ll find that processors with lower nm values are more energy-efficient than those with larger nm values. This reduced power consumption prevents overheating and potentially prolongs your device’s battery life.

Performance: Processors with smaller transistors allow more transistors to be packed into a given area. This higher transistor density improves performance, as the processor can handle more tasks simultaneously.

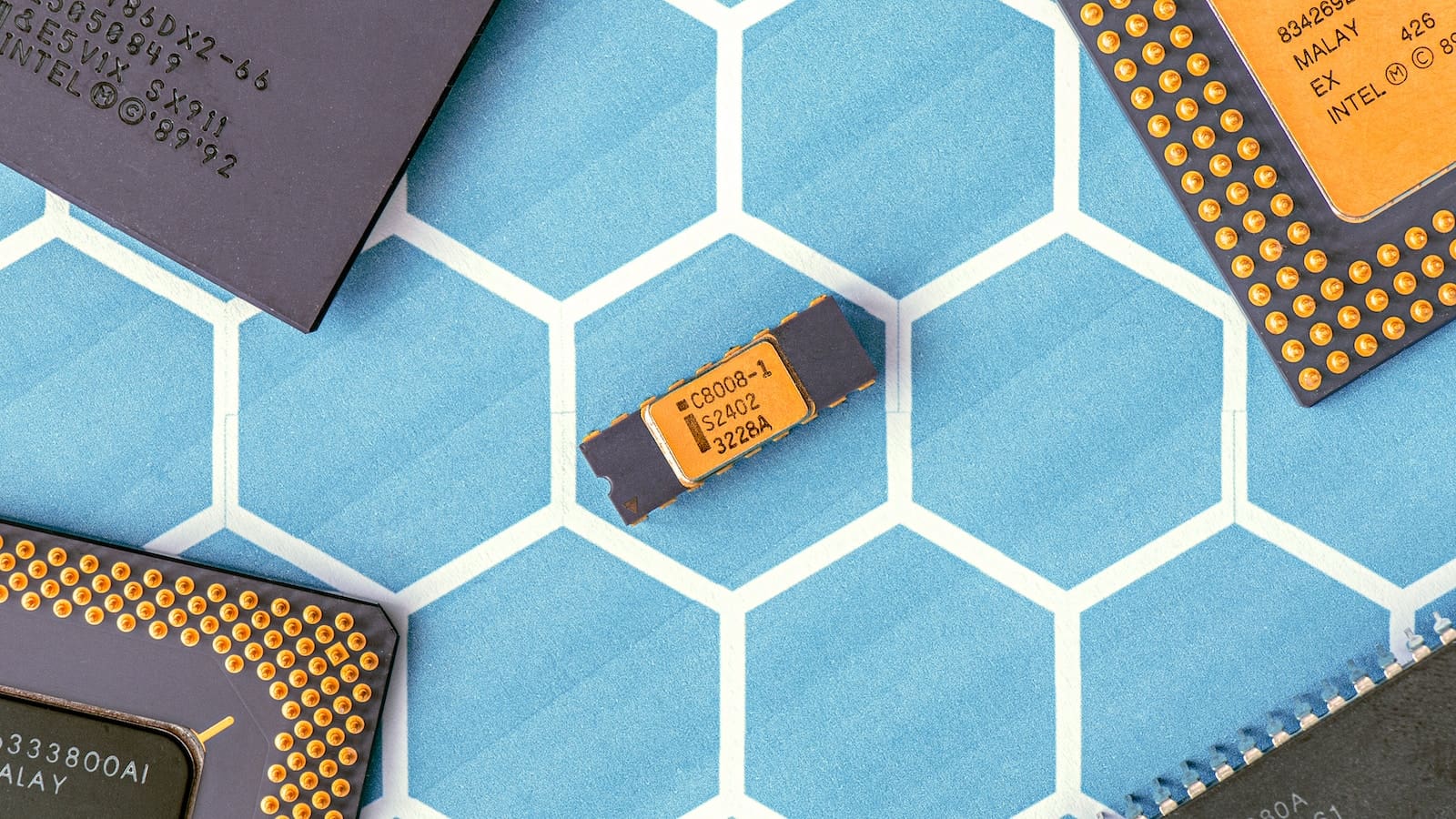

Fabrication process: Transitioning from larger to smaller transistor sizes requires a complex and advanced fabrication process. Over the years, we have seen a reduction in transistor size, from 14nm to 10nm, 7nm, and now 5nm processors. This miniaturization trend is anticipated to continue, pushing the boundaries of computing power.

Comparative Analysis Between Processor Sizes

5nm Processor Size

The 5nm processor size offers cutting-edge performance and energy efficiency compared to its counterparts. With an approximate transistor density of 171.3 million per mm², you can expect higher performance and lower power consumption in devices utilizing this technology. This size suits advanced applications, such as AI, machine learning, and data center solutions, requiring significantly high computational power.

Manufacturers like Apple and TSMC have already implemented 5nm processors in their products, leading to notable improvements in the performance and battery life of devices like the iPhone 12 and A14 Bionic chip.

7nm Processor Size

The 7nm processor size is still an excellent choice for modern devices, balancing performance, power efficiency, and cost-effectiveness. With a transistor density of around 91.2 million transistors per mm², industry leaders like AMD, Samsung, and Qualcomm have widely adopted this technology in high-performing products like the Ryzen 3000 series and Snapdragon 855.

Devices utilizing 7nm processors benefit from improved performance and reduced power consumption, making them ideal for high-end smartphones, laptops, and gaming consoles. However, it’s important to note that the 5nm process provides a slightly better performance and efficiency.

10nm Processor Size

The 10nm processor size, with a transistor density of about 52.5 million transistors per mm², offers respectable performance and energy efficiency improvements compared to 14nm. You can find this technology in various devices, as it has been adopted by companies such as Intel and MediaTek for their respective product lineups.

While the 10nm process significantly upgrades the older 14nm technology, it falls short compared to 7nm and 5nm processor sizes for performance and power consumption improvements.

14nm Processor Size

The 14nm processor size, characterized by a transistor density of around 37.5 million transistors per mm², has been a popular choice for various applications, especially in general computing and entry-level products. The 14nm technology advancements have allowed manufacturers like Intel to optimize their product range’s performance and energy efficiency, such as the Core i5 and i7 processors.

Although the 14nm process is more affordable and accessible than its smaller counterparts, it must recognize that it cannot deliver the same performance and energy efficiency level as 5nm, 7nm, or 10nm processors.

As a quick summary:

- 5nm Processor Size: Best-in-class performance and energy efficiency for advanced applications.

- 7nm Processor Size: Excellent performance and power efficiency, ideal for high-end products.

- 10nm Processor Size: Respectable performance improvements over 14nm but falls short compared to 5 and 7nm.

- 14nm Processor Size: Affordable and accessible for entry-level products but the lowest performance compared to the other options.

Factors Affecting the Size of a Processor

Regarding processors, their size is described in terms of the manufacturing process, which refers to the width of the transistors used in the processor. Common sizes include 14nm, 10nm, 7nm, and 5nm, with smaller sizes improving performance and power efficiency. Several factors can affect the size of a processor:

Materials and Manufacturing Techniques: The materials used for fabricating transistors directly impact their size. As technology advances, manufacturers develop new techniques that enable the creation of smaller transistors. For example, silicon was the primary material, but now, other options like gallium nitride (GaN) show potential for smaller, more power-efficient transistors.

Power Consumption and Heat Dissipation: As transistors shrink, they also consume less power and generate less heat. This is a critical factor when designing processors, as maintaining safe temperatures and power levels is vital for reliable and efficient operation. Engineers need to consider not only the size of the devices but also the materials and architecture to manage heat and power consumption effectively.

Cost and Yield: Processor fabrication involves significant costs, especially when innovating and transitioning to new manufacturing processes. Smaller sizes require more advanced equipment, which can increase production costs. Additionally, the yields (percentage of functional processors after fabrication) can be lower initially due to process development challenges. As the process matures and engineers refine the manufacturing techniques, yields should improve over time, affecting the decision-making of the processor size.

Market Demand: The demands of customers, which can vary depending on the application or industry, also play a role in determining the size of a processor. For instance, mobile devices might prioritize power efficiency and compactness, while high-performance computing systems may focus on processing power. Manufacturers must consider these varying customer needs when choosing a size for their processors.

In summary, processor size is determined by various factors, including materials, manufacturing processes, power consumption, heat dissipation, cost, yield, and market demands. Balancing these factors is essential in producing efficient, cost-effective, and suitable processors for diverse applications.

Impact on Performance and Efficiency

Performance of 5nm Processors

The 5nm processor technology brings significant improvements in both performance and efficiency. With a smaller node size, it is possible to fit more transistors on a single chip, leading to better processing power and faster operations. In addition, the smaller size reduces the amount of power required for each transistor, ultimately increasing energy efficiency. You can expect a boost in performance and lower power consumption compared to previous generations.

Performance of 7nm Processors

7nm processors show notable improvements compared to 10 and 14nm processors. The reduced node size increases transistor density, resulting in better performance and higher efficiency. You will notice a reduced power consumption, allowing for longer battery life in smartphones and laptops. However, the gains in efficiency are not as significant as those seen in the jump to 5nm processors.

Performance of 10nm Processors

10nm processors offer a substantial upgrade from their 14nm counterparts. The reduction in node size allows for increased transistor density, translating into higher performance and improved efficiency. Power consumption is lower than with 14nm processors, contributing to enhanced battery life. However, the performance difference between 10 and 7nm processors is less pronounced than the jump from 14nm to 10nm.

Performance of 14nm Processors

14nm processors have been widely used in various devices for several years, and while they still deliver solid performance, they are now considered outdated compared to smaller node sizes. As the node size decreases, processors become more efficient and powerful, so the difference in performance becomes more noticeable. Devices featuring a 14nm processor may consume more energy and provide less processing power than their more advanced counterparts. Opting for a device with a smaller node-size processor is recommended for the best combination of performance and efficiency.

Technological Advancements in Processor Sizes

In recent years, the semiconductor industry has made remarkable strides in reducing the size of transistors in processors. You may have heard about 5nm, 7nm, 10nm, and 14nm processor sizes. These numbers represent the size of the transistors and the distance between them, measured in nanometers (nm).

As manufacturers develop smaller transistor sizes, processor performance and efficiency significantly improve. Reduced sizes allow more transistors to be packed into the same chip area, increasing processing power. Additionally, smaller transistors consume less power, thus reducing power consumption in devices.

The race to achieve smaller nodes has been highly competitive, with leading manufacturers like Intel, AMD, TSMC, and Samsung at the forefront of innovation. The main benefits of these advancements include:

- Higher performance: With more transistors packed into a chip, processors can handle multiple tasks simultaneously, resulting in increased performance.

- Energy efficiency: Smaller transistors require less power to switch on and off, reducing overall power consumption and extending device battery life.

- Compact form factors: As transistors shrink, chipsets become more compact, allowing thinner and lighter devices.

Currently, 5nm technology represents the cutting edge in processor design. For example, Apple’s A14 Bionic chip is built on a 5nm process and offers improved energy efficiency and performance compared to its predecessor. Meanwhile, TSMC and Samsung are pushing the boundaries even further, with plans to introduce the 3nm process in the near future.

In conclusion, the ongoing shift towards smaller transistors has greatly benefitted the semiconductor industry. These advancements provide faster and more energy-efficient devices, improving user experience and promoting innovation in various sectors. As technology evolves, the benefits of these ever-shrinking transistor sizes will likely become more apparent and transformative.

Future Trends in Processor Sizes

As technology evolves, you’ll see a continuous reduction in processor sizes. Manufacturers use technologies such as 5nm, 7nm, 10nm, and 14nm to produce more energy-efficient and powerful chips. Experts expect even smaller nodes to become the norm in the coming years.

Companies like TSMC and Intel are already investing heavily in research and development for sub-5nm process nodes. Their progress will potentially lead to 3 and 2nm processor sizes in the early-to-mid 2020s. These advancements will enhance performance, reduce power consumption, and increase transistor density.

Furthermore, the increasing adoption of extreme ultraviolet (EUV) lithography technology opens up new possibilities for smaller, more complex chip designs. Industry leaders are striving to overcome the challenges related to heat dissipation and quantum tunnelling when transistors are tightly packed.

To summarize, future trends in processor sizes focus on developing even smaller nodes like 3nm and 2nm with better energy efficiency and performance. Progress in EUV lithography technology will further enable the production of more intricate and powerful chips. As a user, you can expect greater processing capabilities and enhanced performance in your devices due to these advancements.