Brushes Nickel and Stainless steel are the two most widely used industrial metals. Both of them are used in engineering manufacturing, and both of them have some uncanny similarities but as well as have distinguishing differences too. Appearance-wise, both brushed nickel and Stainless Steel look alike.

Key Takeaways

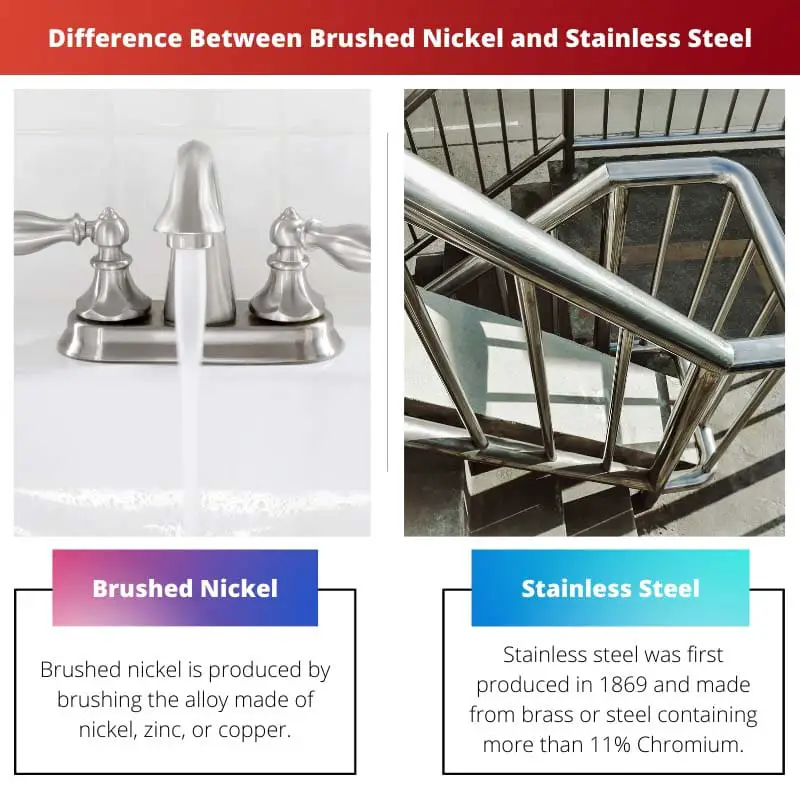

- Brushed nickel is a nickel-plated alloy with a brushed texture, while stainless steel is an alloy of steel, chromium, and other metals with a smooth, polished finish.

- Brushed nickel has a warmer, more traditional look than stainless steel, with a cooler, more modern look.

- Brushed nickel is more susceptible to scratching and wear than stainless steel, which is more durable and corrosion-resistant.

Brushed Nickel vs Stainless Steel

Brushed Nickel has a semi-glossy or matte finish, easily displays spots, is more challenging to maintain, has an inferior type of finish, and is costly. Stainless Steel has a shiny and metallic finish, is highly resistant to spots, easier to maintain, has a superior type of finish and is not costly.

Brushed Nickel is widely used in constructive work like making buildings, manufacturing industrial machinery, etc. It is used as a plating material. The composition of brushed nickel contains copper, zinc, or nickel metals. Brushed nickel is brushed and has a semi-glossy finish due to its fine intricate brushing.

Stainless steel must surely be found in every household if not at least 10% of the house contains products of stainless steel. It is a very glossy finish, silver in color. Stainless steel is a very durable metal. Its extent of usage is insane. It is used for making industrial products jewellery to so much more.

Comparison Table

| Parameters of Comparison | Brushed Nickel | Stainless Steel |

|---|---|---|

| Composition | Brushed nickel is produced by brushing the alloy made of nickel, zinc, or copper. | Stainless steel was first produced in 1869 and made from brass or steel containing more than 11% Chromium. |

| Melting Point | The melting point of brushed nickel is 1,455 C. | The melting point of stainless steel is 1525 C. |

| Cleaning | The dirt on brushed nickel has to be cleaned with a solution of vinegar and water. | The dirt on stainless steel can be easily cleaned off by wiping with a cloth or any paper tissue. No solution Is need. |

| Finish | Brushed nickel has a semi-glossy finish due to the intricate brushing process. | Stainless steel has a glossy metallic finish. |

| Colour | The color of brushed nickel varies from silvery white to a warm or earthy tone yellow. | The color of stainless steel is metallic silver. |

What is Brushed Nickel?

Brushed Nickel is an alloy made of copper, zinc, and nickel plating. It is silvery in color and has a semi-glossy finish to it. Due to its complex brushing technique, it may develop a small, consistent groove-like structure. Brushed nickel might very easily catch dirty, which becomes difficult to clean off.

They are very much vulnerable to scratches. Brushed nickel is very much prone to corrosion. They are also very much attacked by rust and thus may decay due to rust. Brushed nickel has a warm tone present to it.

Although brushed nickel might vary from a silvery-white tone to earthy brown tone color, Nickel is a historical metal and may give an antique and unique look if used in furnishing.

Due to minute brushing processing, brushed nickel has a texture. Brushed nickel is used for engineering purposes and electro-plating purposes. Even with all the drawbacks, brushed nickel is widely used for furnishing the house, especially kitchen furnishing, even though it has little to no resistance to rusting.

Brushed nickel can be easily cleaned with a solution of vinegar and water. It has low maintenance as its surface is not smooth, and thus even scratches do not hamper its appearance and look.

What is Stainless Steel?

Stainless steel is a metal alloy that is made of 11% chromium. Stainless steel has been used everywhere since the 1900s, and ever since, its demand in the market has never dropped. It has a smooth, shiny finish and metallic silver in color.

It is a martial composed of carbon and iron. Stainless steel is a very durable material, and it is used in the process of building making. Maintenance of stainless steel is quite easy and effortless.

Due to its glossy and slippery finish, dirt cannot sit on it, and neither does stainless steel catches rust. Stainless steel can be cleaned very easily by only wiping it with a cloth or sponge.

Stainless steel has somewhat properties of resisting heat. The element that is added to stainless steel to prevent corrosion is nitrogen. Chromium-containing steel was first produced in 1869 for the purpose of bridge construction.

Later, by proceeding with the innovation of chromium-containing steel, in 1904, stainless steel was produced for the first time ever. There are different grades of stainless steel depending upon the number of chromium added in the steel or brass ore, which is electroplated to form stainless less.

Main Differences Between Brushed Nickel and Stainless Steel

- The melting point of brushed nickel is 1455 C, whereas the melting point of stainless steel is 1525 C.

- Brushed nickel is produced by brushing the alloy made of nickel, zinc, or copper. Stainless steel is made from brass or steel containing more than 11% Chromium.

- The dirt on brushed nickel has to be cleaned by a solution of vinegar and water, but the dirt on stainless steel can be easily cleaned off by wiping it with a cloth or any paper tissue.

- Brushed nickel has a semi-glossy finish due to the intricate brushing process, whereas Stainless steel has a glossy metallic finish.

- The color of brushed nickel varies from silvery white to a warm or earthy tone yellow and the color of stainless steel is a metallic silver.

I never knew there were so many differences between brushed nickel and stainless steel. This article was very informative.

I appreciate the detailed analysis of the properties and uses of brushed nickel and stainless steel. The article offers valuable knowledge for individuals with an interest in industrial metals.

This article provides detailed and comprehensive information about the characteristics and uses of both brushed nickel and stainless steel. I found the comparison table particularly useful and engaging.

I also appreciate the thoroughness of the comparison provided in the article. It’s a great resource for anyone interested in these metals.

I agree, the detailed comparison is very helpful in understanding the distinctions between brushed nickel and stainless steel.

I am fascinated by the historical context and unique characteristics of brushed nickel. The article does a great job of highlighting its vulnerabilities and applications.

I found the detailed explanation of brushed nickel and stainless steel to be very informative and engaging. The article effectively highlights the unique features of each metal.

The article’s explanation of stainless steel as a durable material with easy maintenance is particularly noteworthy. It’s interesting to learn about the advantages of stainless steel over brushed nickel.

The information on the composition, finish, and cleaning methods of brushed nickel and stainless steel is meticulously presented. This article serves as an excellent resource for understanding the differences between these metals.

The information about the composition, melting point, color, and cleaning methods of brushed nickel and stainless steel is quite enlightening. It’s impressive to see such a detailed analysis.

The detailed comparison table and the descriptions of brushed nickel and stainless steel provide valuable insights into their respective characteristics. It’s an informative and well-researched article.

The comparison between brushed nickel and stainless steel provides valuable insights into their distinctive features and properties. It’s a well-presented and educational read.