Construction work is not an easy task. One small mistake will lead to bigger consequences. Two tools are available for making the woodworking and the construction work smoother.

One is Counterbore, and the other is Countersink. They are very useful and used in wide areas. The best part is we can even make the designs using Counterbore and Countersink tools on the computer.

Key Takeaways

- Counterboring creates a flat-bottomed hole with a larger diameter to allow a fastener’s head to sit flush or below the surface.

- Countersinking produces a conical hole for accommodating the tapered head of a screw or fastener.

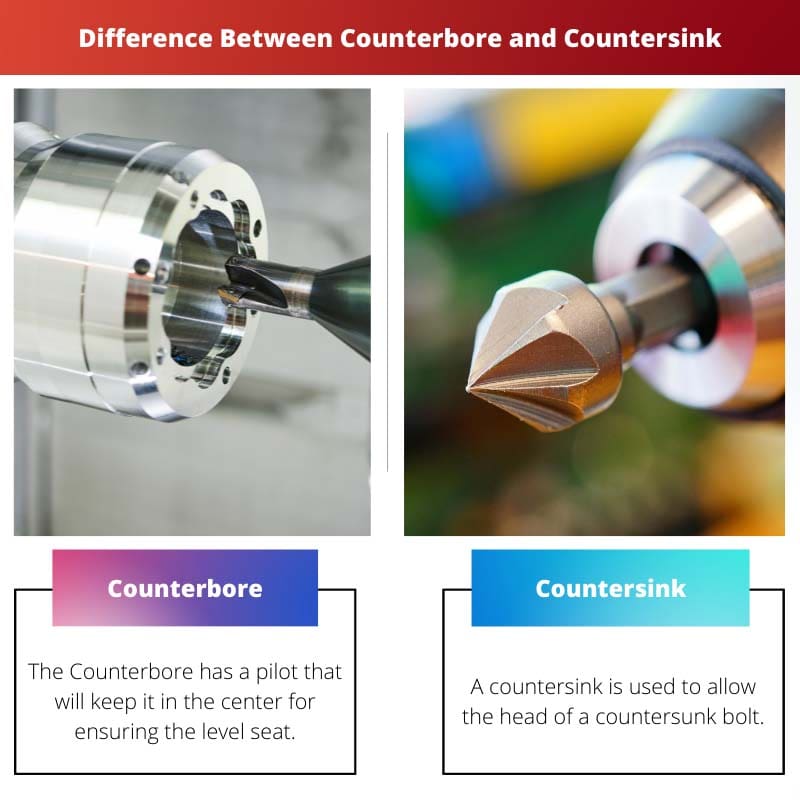

- Counterbore tools have cylindrical cutting edges, while countersink tools have angled cutting edges.

Counterbore vs Countersink

A counterbore is a cylindrical recess larger than the diameter of the screw head, used to provide a flat, level surface for the screw head to sit on. It is drilled using a drill bit with a pilot tip and a larger cutting diameter. Countersink is a cone-shaped recess that creates a tapered hole for flat-head screws or rivets.

The Counterbore has a pilot to keep it in the centre to ensure a level seat. One of the advantages of using a counterbore is that it will help open the large holes so that the screw can easily fit.

They are used only for a single purpose. The cutting edges in the counterbore can be either straight or spiral teeth. A counterbore is a cylindrical recess.

A countersink is used to allow the head of a countersunk bolt. During the drill work, it creates an area in the wood to match the shape of the screw head.

Countersinking a screw means you will drive the screw below the surface. The head of the countersink will sink into the workpiece’s surface. If you notice it carefully, you can see that it tapers towards the shank.

Comparison Table

| Parameters of Comparison | Counterbore | Countersink |

|---|---|---|

| Shape | Cylindrical flat-shaped | Cone-shaped |

| Size of hole | It is bigger than a countersink. | It is smaller than a counterbore. |

| Definition | It is a circular hole with sections at different diameters. | It is a conical hole that is cut into an object. |

| Use | It is good for holding strength. | It is good for holding stronger objects. |

| Good for | Woodworking and thin sheet metal | Automotive and construction |

What is Counterbore?

It is a drilled hole having a wider section at the top area. It is used for cutting the spot face. A small amount of material will be used to make the surface flat. It is also used for creating a perpendicular surface on a non-perpendicular surface.

The main types of counterbores are aircraft counterbores, fillister head screw counterbores, back counterbores, cap screw counterbores, and blade counterbores. The drill in the counterbore is made of solid carbide.

The drills have four flutes with 15 helices. Depending on the tool chart before purchasing, the user can select the correct one. The shape of the counterbore is cylindrical and flat shaped.

The hole in the counterbore has a flat bottom, allowing a screwer or fastener to fit inside it. Any instrument made in this form is called Counterbore.

The counterbore is also used for drawing purposes. It has a hole that provides the recess for the head of the screw. It can be a flat surface for exposed nuts or bolts.

You need to create a sketch in sketch points to make counterbores in shapes. You need to select the points where you would like to create holes.

Finally, you need to select the whole style. A manufacturer can hide the fastener completely during the entire journey process of the counterbore.

What is Countersink?

It is a conical hole cut into a manufactured object. It is for ensuring that the acres sit flush with the workpiece. It will match the angle of the screw by matching the conical hole.

When the screw is fully engaged, it will sit tightly or below the surface. There is a relation between the countersink and the drill. Countersinks are used for countersinking drill holes. It helps widen the drill hole, facilitating the subsequent tapping.

It is called a countersink because the screw will be sunk into the countersink. Countersink has been manufactured with six angles such as 120, 100, 82, 90, 60, and 110.

The two most common angles used in the countersinking process are 82 and 90. But in the aerospace industry, they use 100 for fasteners.

During MDF fastening, the countersink plays an important role in preventing the holes from mushrooming. For this, you have to drill countersinks on both faces.

And it should also be drilled on the mating surface of the mating piece. This helps the parts to sit fully and provides relief to all the parts. Countersink is mainly used in removing burrs that are left from drilling or tapping operations.

A coach bolt can be countersink to make a shallow hole in the wood. This will make a flat part so that the head of the bolt will fit in. The advantage of using a countersink is that it will increase the structural lifetime and protect them.

Main Differences Between Counterbore and Countersink

- The shape of the counterbore is cylindrical and flat shaped. On the other hand, the shape of the countersink is conically shaped.

- The hole in the counterbore will be bigger than the countersink. On the other hand, the size of the hole in the countersink will be smaller than the counterbore.

- A counterbore is a circular hole that has sections at different diameters. On the other hand, the countersink is conical and has been cut into an object.

- The advantage of using a counterbore is it is good for holding strength. On the other hand, the advantage of using a countersink is it is good for holding stringer objects.

- The counterbore is mainly used in woodworking and thin sheet metal. On the other hand, the countersink is mainly used in automotive and construction.

- https://iopscience.iop.org/article/10.1088/1755-1315/632/4/042068/meta

- https://ieeexplore.ieee.org/abstract/document/8599335/

This article made me realize the importance of these tools in construction and woodworking. It’s informative and intriguing.

The impeccable detailing and comparison between the two is outstanding. This article is marvellous.

Couldn’t agree more! The extensive information provided here is enlightening.

You’re correct, the article is an excellent guide for understanding the key differences between the two tools.

The article has failed to captivate my attention and interest. It’s a long piece with too much information and it’s overwhelming.

It’s interesting to see how much research has been put into creating this piece. The depth of information is impressive.

The author has done an excellent job at simplifying and presenting complex concepts in a clear and concise manner. The details are very well articulated.

The article has definitely created a stir. A highly engrossing read.

Absolutely, the article is a testament to the outstanding intellectual prowess of the author.