During any construction or remodelling project, the most difficult job is to select the surface material. There is a wide range of options available as a surface material.

The common characteristics of all the materials are durability, resistance, and visually appealing appearance. The two common materials are Quartz and Corian.

Key Takeaways

- Quartz is a natural stone material consisting mainly of silicon dioxide, while Corian is a solid surface material created from a mix of acrylic polymer and natural minerals.

- Quartz countertops boast higher durability and heat resistance than Corian countertops.

- Quartz offers a more natural look and has a higher resale value than Corian, which comes in a wider variety of colors and patterns.

Quartz vs Corian

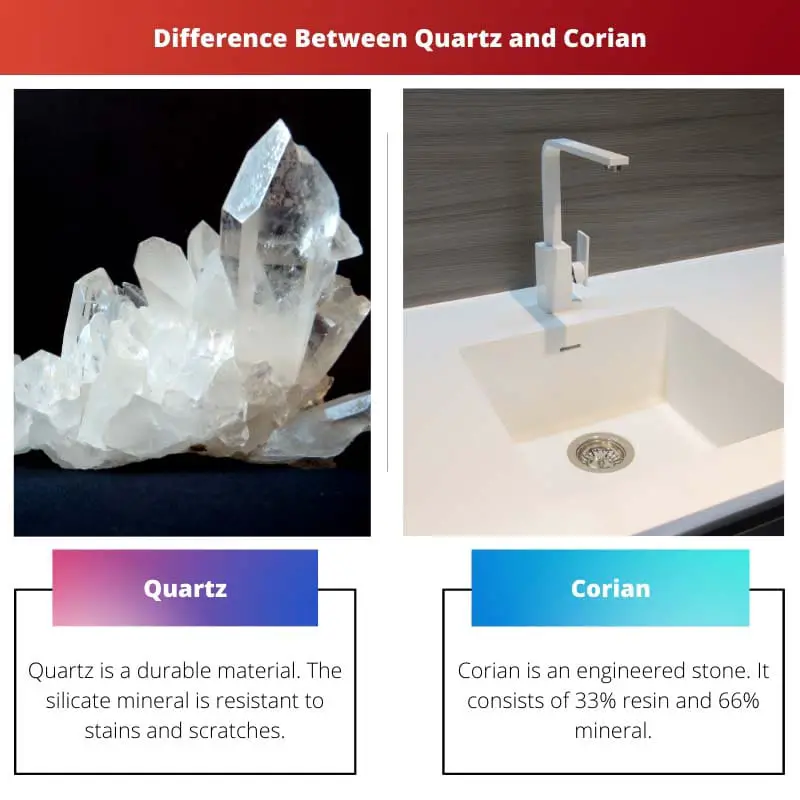

Quartz is a hard, shiny and natural mineral composed of silica and oxygen. This stone is resistant to heat, water and scratches. Corian is a man-made material composed of resin and minerals. It is used for washbasins, countertops and wall panels. This material is susceptible to stain and scratches.

Quartz is a durable material. The silicate mineral is resistant to stains and scratches. It is a traditional stone used in construction projects for years. It also includes some man-made substances like pigments and resin binders.

Quartz has a wide range of variants depending on the microstructure and color. On the other hand, Corian is an engineered stone. It consists of 33% resin and 66% mineral.

Corian is prone to stains and scratches. It can get easily scorched. The parent manufacturer of Corian is DuPont. It can be moulded into any shape, size, or dimension. It is available in a wide range of colors and shades. The installation cost of Corian slabs is over $35.

Comparison Table

| Parameters of Comparison | Quartz | Corian |

|---|---|---|

| Manufacture | Natural stone | Man-made surface material |

| Constituent | It is a silicate mineral | It consists of 33% resin and 66% mineral |

| Use | Oscillators for watches, radios, electronic games, computers, clocks, cell phones, electronic meters, televisions, and GPS equipment | As countertops and benchtops |

| Resistance | Quartz is water, heat, stain, and scratch-resistant | Corian is heat resistant but prone to water, stains, and scratches |

| Cost | Ranges between $40 to $200 | Ranges between $45 to $70 |

What is Quartz?

Quartz is a crystalline mineral. It consists of silica. The specific gravity of quartz is 2.65. On the Mohs Scale of Hardness, quartz has been given 7. It has a density of 2.65 g/cc. The crystal system of quartz is trigonal.

It is ideally a six-sided prism extending with a six-sided pyramid at the end. It is a crystalline form of molten magma.

Quartz can exist in two forms. The two forms are normal alpha-quartz, which is trigonal, and beta-quartz, which is hexagonal. The word “quartz” is derived from the German word “Quarz” and was referred to as icy cold.

Well-formed quartz is found to have ‘dusre’, a layer lining avoid. Quartz is one of the most abundant minerals on the earth’s surface.

Quartz can be classified into several variants like rock crystal, citrine, amethyst, ametrine, chalcedony, rose quartz, aventurine, carnelian, agate, Jasper, dumortierite quartz, tiger’s eye, milky quartz, smoky quartz, onyx, prasiolite, Herkimer diamond, and others.

Every variant of quartz is not naturally occurring. Some are manufactured by various man-made processes. Quartz can form at all temperatures. It is a durable and ubiquitous natural stone.

Quartz has a vitreous lustre. It interacts with light in the same fashion as glass does. Quartz has a white streak in powder form. It shows stability in high temperatures and on exposure to chemicals and acids.

What is Corian?

Corian is a surface material manufactured by DuPont. The main composition of Corian is acrylic polymer and alumina trihydrate. It was first launched in the year 1967.

It is available in three thickness variants – 6 mm, 12 mm, and 19 mm. The material has an even distribution of color and particulate matter.

The patent of Corian is a DuPont chemist called Donald Slocum. Corian offers a wide range of options to choose from. It is available in 100 colors. It uses “Deep color” technology to create Corian in darker and deeper colors.

These variants show greater resistance to heat, stains, scratches, and water. It contains 33% synthetic polymers and 66% natural material.

The characteristics of Corian are non-porous, seamless and contemporary appearance, repairable, renewable, can be shaped and molded into any form, and thermoformable.

It can resist heat up to 100° C but can be damaged in extreme heat. It does not lose its color or appearance for decades. It is prone to stains and scratches.

Corian emits small amounts of volatile organic compounds (VOC) but is free from major heavy metals and is nontoxic. It is a hygienic product and hence is widely used in hospitals and restaurants where maintenance of sanitary conditions is essential.

Workers in the manufacturing industries of Corian should wear a proper respirator as the dust of Corian can cause idiopathic pulmonary fibrosis and other respiratory diseases.

Main Differences Between Quartz and Corian

- Quartz is a natural rock, while Corian contains polymer and natural minerals.

- Quartz is expensive, while Corian is cost-effective.

- Quartz is durable and resistant to stains and scratches, while Corian is weaker and less durable than Quartz.

- The bonding adhesive on the Quartz surface is visible, while the bonding adhesive on the Corian surface is invisible.

- Quartz provides a luxurious and royal look, while Corian provides a contemporary appearance.

- https://scholar.google.com/scholar?cluster=7172295449995374071&hl=en&as_sdt=2005&sciodt=0,5

- http://erp.jung-a.com/zovgzaik/brzd-stainless-steel-3182447.html

The detailed comparison of Quartz and Corian provides valuable insights about the suitability of these materials for different applications.

The article has highlighted the key differences effectively. It is a valuable resource for anyone seeking to understand the pros and cons of Quartz and Corian.

Absolutely, the detailed insights are beneficial in determining the optimal surface material for varied architectural and design applications.

I appreciate the comprehensive breakdown of attributes that help in distinguishing between Quartz and Corian.

It is important to consider the cost and durability of the material to be used. This article gives a detailed comparison and explanation about quartz and Corian.

The comparison between Quartz and Corian was very informative. It has helped me in considering the best option for my project.

I totally agree. The details provided in the article are of great significance for people undergoing construction or remodelling projects.

The information provided in the article was very educational and has broadened my understanding of surface materials.

A great comparison between Quartz and Corian. It helps in making an informed decision based on specific requirements for surface materials.

Indeed, this detailed comparison offers practical information for architects, designers, and homeowners.

The article fails to adequately address the environmental impact of Quartz and Corian in their production and usage.

Yes, I agree with you. The environmental aspects should have been discussed in this article.

The post was very insightful and provides a comprehensive comparison of Quartz and Corian. The characteristics and differences are clearly laid out.

I found the information very enlightening and extremely helpful in making a decision about the surface material for my project.