Once someone develops that, creating an urge in them, it is something that cannot be paused. You will need to create as many ways as you want to create something.

And this will be the point where it will not matter if you are a 3D printer hobbyist or a teacher making a maker space. This is where the Beamo flux and the Glowforge laser cutters enter, as they play a key role here.

With a Glowforge, it is easy to cut almost anything- wood, paper, fabric, leather, berlin, mylar, rubber, and many more.

Key Takeaways

- Glowforge is an all-in-one 3D laser printer, cutter, and engraver with user-friendly software, making it suitable for various skill levels.

- Beamo, a compact laser cutter and engraver offers a more affordable option for hobbyists and small businesses than Glowforge.

- Both devices support various materials, like wood, leather, and acrylic, expanding creative possibilities for users.

Glowforge vs Beamo

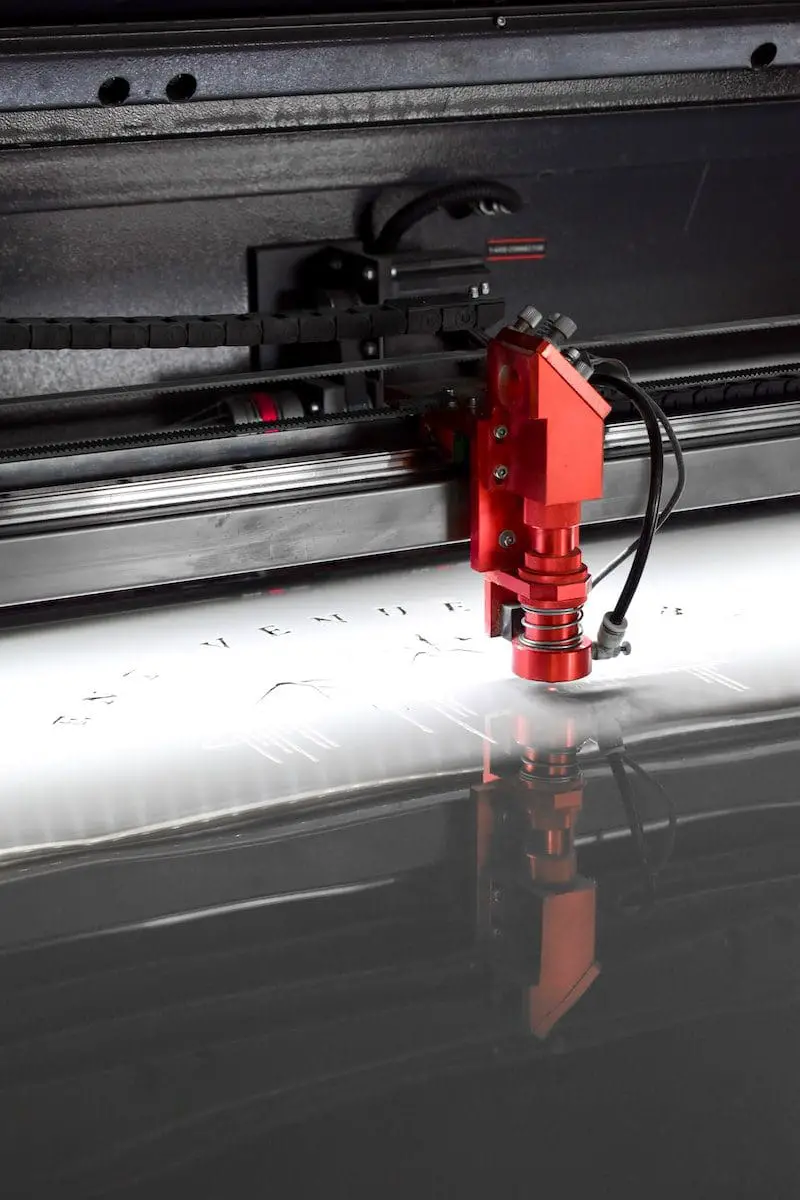

Glowforge is a 3D laser printer that uses a beam of light to cut and engrave efficiently along with a larger area for work which makes it different from traditional 3D printers. It can even cut heavy materials like aluminium. A Beamo is a small desktop laser cutter and engraver that is cheaper.

The Glowforge, a 3D printer, creates many beautiful and creative things just at the push of a button. With a Glowforge, it is easy to cut almost anything, say- wood, paper, fabric, leather, derlin, mylar, rubber, and many more.

Along with all these, it can also engrave glass with coated metal, aluminium, some phones, tablets, titanium, laptops, and many more such items.

A Beamo is a perfect item for someone who is a 3D printing maker. Beamo allows you to create and cut on literally any platform or surface you can think of, and all this with only a fraction of the cost you have a budget for than the other lasers with carbon dioxide.

It is said by the printing makers that a Beamo is peppered with life if the variety is the spice of life.

Comparison Table

| Parameters of Comparison | Glowforge | Beamo |

|---|---|---|

| What are they? | The glowforge, a 3D printer, creates many beautiful and creative things just at the push of a button. | A Beamo is a perfect item for someone who is a 3D printing maker. Beamo allows you to create and cut on literally any platform. |

| Cuttings | With a Glowforge, it is easy to cut almost anything, say- wood, paper, fabric, leather, derlin, mylar, rubber, and many more. Along with all these, it can also engrave the glass with coated metal, aluminum, and many more items. | Beamo allows you to create and cut on literally any platform or surface you can think of and all this with only a fraction of the cost you have a budget for than the other lasers with carbon dioxide. |

| 3D printers | They are very different from any traditional 3D printer. | They have a slight effect on 3D printers but not the same. |

| Heavy materials | Glowforge can cut heavy materials like glass with coated metal, aluminum, and many more items. | Beamo uses only about a reasonable amount of 615mm by 445mm on the desk that you are working on, which is quite a heavier material in weight. |

| Cost | Glowforge costs quite high. | Beamo will save you up to at least $1000. |

What is Glowforge?

The Glowforge, a 3D printer, creates many beautiful and creative things just at the push of a button. With a Glowforge, it is easy to cut almost anything, say- wood, paper, fabric, leather, derlin, mylar, rubber, and many more.

It can also engrave glass with coated metal, aluminium, phones, tablets, titanium, laptops, and many more.

There are plenty of things that a Glowforge can make in any creative way with plenty of different materials like wood, fabric, felt, leather, and many more such materials.

People might ask how Glowforge is different from any other 3D printer. The answer is traditional 3D printers use additive manufacturing while Glowforge uses subtractive manufacturing.

What is Beamo?

A Beamo is a perfect item for someone who is a 3D printing maker. Beamo allows you to create and cut on literally any platform or surface you can think of, and all this with only a fraction of the cost you have a budget for than the other lasers with carbon dioxide.

The printing makers say that a Beamo is peppered with life if the variety is the spice of life.

Talking about the air assist, Beamo uses only about a reasonable amount of 615mm by 445mm on the desk that you are working on, which makes it feel nice and comfortable, and this is because the sheets of beamo come with metal constructions and they come along with pre-aligned mirrors of lasers that have almost everything that you will require to run it.

Main Differences Between Glowforge and Beamo

- The main difference between Glowforge and Beamo is that glowforge, which is a 3D printer, creates many beautiful and creative things just at the push of a button, while Beamo is a perfect item for someone who is a 3D printing maker. Beamo allows you to create and cut on literally any platform.

- With a Glowforge, it is easy to cut almost anything, say- wood, paper, fabric, leather, derlin, mylar, rubber, and many more. Along with all these, it can also engrave the glass with coated metal, aluminium, and many more items, while Beamo allows you to create and cut on literally any platform or surface you can think of, and all this with only a fraction of the cost you have a budget for than the other lasers with carbon dioxide.

- Glowforges are very different from any traditional 3D printers, while Beamo has a slight effect on 3D printers but not exactly the same.

- Glowforge can cut heavy materials like glass with coated metal, aluminium, and many more items, while Beamo uses only about a reasonable amount of 615mm by 445mm on the desk that you are working on, which is quite a heavier material in weight.

- Glowforge costs quite high, but Beamo will save you up to at least $1000.

- https://books.google.com/books?hl=en&lr=&id=R4qxOQZV9T0C&oi=fnd&pg=PR3&dq=what+are+3d+printers&ots=pCDfI2MTUt&sig=bEugCXx-ROBpT8vbETjAyIn1Qko

- https://www.emerald.com/insight/content/doi/10.1108/LHT-06-2014-0056/full/html