Manufacturing businesses use these laser printers and printers for daily manufacturing processes. They sound similar in their names and techniques, but they do have a difference in their process and techniques.

The Glowforge uses subtractive manufacturing, and the 3D Printer uses additive manufacturing. Glowforge cuts fabrics, wood, paper, and leather, but the 3D Printer does not.

Key Takeaways

- Glowforge is a laser cutting and engraving machine, while 3D printers create 3D objects from a digital file.

- Glowforge uses laser technology to cut and engrave various materials, while 3D printers layer materials to create three-dimensional objects.

- Glowforge is ideal for creating customized designs, while 3D printers are better suited for creating complex geometric shapes.

Glowforge vs 3D Printer

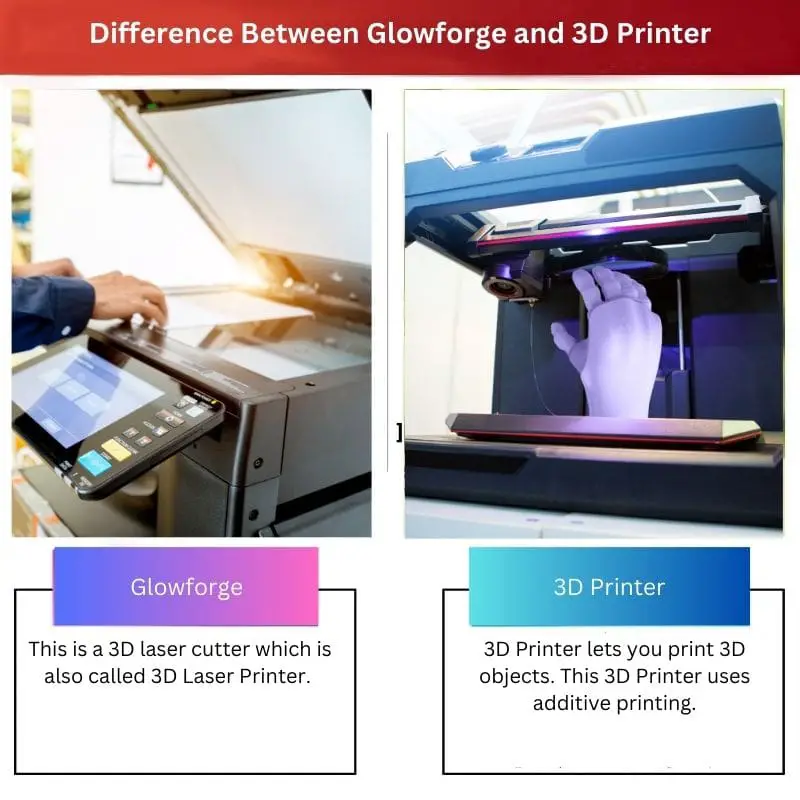

The difference between Glowforge and 3D Printer is Glowforge is a 3D laser printer, but 3D Printer is not a laser printer. Glowforge is a laser printer that uses subtractive manufacturing, and 3D Printer uses additive manufacturing. Glowforge can cut fabrics, wood, and paper, but 3D Printer cannot cut fabrics or wood.

Glowforge is a 3D laser cutter that can cut any length of the workpiece. It is very easy to use and helps to create ornaments, plaques, and costers with intricate designs. The quality is very professional. The size is good, and the price is good. The work is faster using this.

A 3D Printer is a machine that prints 3D objects. This lets you print any object for any material very fast. The cost is low and does all the work. It uses the additive printing process and completes the work in no time. It does the work in a layering process.

Comparison Table

| Parameters of Comparison | Glowforge | 3D Printer |

|---|---|---|

| Type | 3D Laser Printer | 3D Printer |

| Manufacture process | Subtractive | Additive |

| Materials | Fabrics, wood, papers | Papers, bio-material, |

| Support | Yes | No |

| Cuts surfaces like | Flat | Any |

| Work time | Less | More |

What is Glowforge?

This is a 3D laser cutter which is also called a 3D Laser Printer. The usage of this machine is very easy, which lets you cut all types of materials at any length. It is flexible and easy to use. The printer is very powerful and does all the work very fast.

The printer has a good response because it is not very costly and affordable. It has a feeder which can cut any size of any material. It lets to cut the materials by eleven inches. The size and the model are like a large printer. There is a large box-like structure on the front.

This helps the printer to cut any type of material of any size. The top has a metal-bordered start button. The PC will send the instructions to Glowforge, and the start button will begin to flash, it is an indication the information has been sent to Glowforge.

The most important part of the Glowforge is the exhaust fan. It has a four-inch exhaust. It connects the power cable and power switch. Woodcutting causes some fumes, due to which the exhaust fan is an important part of Glowforge. The hose has to be taken care of because it is vital.

What is 3D Printer?

3D Printer lets you print 3D objects. This 3D Printer uses additive printing. This process is about putting the multiple layers of the material until the creation of the object is created. These are thin layers. It is placed in the cross-section of the object. The 3D printer is not a laser printer.

The whole process is different from a laser printer. It uses computer-aided design. It uses a method of layering. It involves materials like composites and plastics, which make the layers and print the 3D object. It looks after the perfect size, rigidity, color, and shape.

3D Printer makes objects very fast and does not take a long time.

The 3D Printer works flexibly. The process is accurate, and it completes the work very fast in no time. These are also known as rapid prototyping. This does not cost much, so there is no waste of money and time. They do not have a community forum. 3D Printers are becoming popular in schools.

Schools have started using this 3D Printer. They started using a 3D Printer so that students could try it on and learn new things with their academics. This technique is a game-changer as it does the big thing.

The schools make the students print many other things like dinosaur bones and robotic pieces.

Main Differences Between Glowforge and 3D Printer

- Glowforge is a 3D laser printer, but the 3D printer is not a laser printer.

- Glowforge uses subtractive manufacturing, but 3D Printer uses additive manufacturing.

- Glowforge cuts fabrics, wood, paper, and leather, but the 3D Printer does not.

- Glowforge has support options and a community forum, but 3D Printer does not have support options.

- Glowforge only cuts flat surfaces, but the 3D Printer has no condition like that.

- Glowforge can be done the work in less amount as compared to a 3D Printer.

- https://www.nature.com/articles/srep06973

- https://www.tandfonline.com/doi/abs/10.1080/08956308.2015.1136980

It’s interesting to see the different applications and processes involved in the Glowforge’s subtractive manufacturing and the 3D printer’s additive manufacturing. These distinctions are crucial in understanding their respective functionalities.

Absolutely, the material capabilities of each machine bring unique benefits to different industries.

The varied applications and materials handled by the Glowforge and 3D printer demonstrate their unique roles in manufacturing. Understanding their key differences is essential for leveraging their capabilities in different industries.

Absolutely, the scope and versatility of these machines make them indispensable tools for bringing creative and functional designs to life.

The comparison table provided is very helpful in understanding the key differences between the Glowforge and the 3D printer. It’s clear that each device has distinct advantages and applications.

Indeed, the table highlights the specific features and functions that make both the Glowforge and 3D printer valuable in different manufacturing scenarios.

The detailed comparison allows for an informed decision when considering these manufacturing technologies for various projects.

The Glowforge’s use of laser technology for cutting and engraving different materials is fascinating. Its applications for customized designs seem very promising.

I’ve always been interested in the capabilities of laser cutters for various materials. The Glowforge seems like a valuable tool for creative and manufacturing projects.

I agree, the precision and speed of the Glowforge are impressive for manufacturing purposes.

The detailed breakdown of the Glowforge and 3D printer functionalities sheds light on their unique attributes. It’s important to consider these aspects when choosing between the two machines for specific manufacturing tasks.

Understanding the capabilities and use cases of the Glowforge and 3D printer is essential for maximizing their potential in various manufacturing settings.

Absolutely, the specific applications and user-friendly features of each device make them valuable in different manufacturing contexts.

The description of the 3D printer’s additive printing process and its applications for rapid prototyping is informative. It’s interesting to see how it’s becoming popular in educational settings.

Absolutely, the educational adoption of 3D printers showcases their potential for innovative learning experiences.

The efficiency and cost-effectiveness of 3D printing in academic environments highlight its value for students’ creativity and learning.

It seems that the Glowforge is more suited for custom designs and intricate work, while the 3D printer is better for creating complex geometric shapes. It’s important to note these distinctions for specific project requirements.

Absolutely, the advantages of each machine depend on the specific needs of the user. It’s essential to consider these aspects before investing in one of them.

The clear distinction between the Glowforge and the 3D printer’s capabilities allows for a comprehensive understanding of their respective roles in manufacturing. This insight is valuable for informed decision-making.

Absolutely, the technical specifications and material handling of each machine provide valuable insights into their operational advantages.

The detailed comparison allows users to identify the most suitable technology for their specific manufacturing requirements, ensuring efficient and effective production processes.

The insights into the Glowforge’s components and operational mechanisms provide a comprehensive understanding of its functionalities and applications.

Both machines are very useful for manufacturing processes, but it’s important to understand their differences in order to make the right choice for one’s business needs.