In this industrialist world, the combination of multifarious metals to produce strong material has ruled the world more than we expected. Coming up with new alloys like clockwork has been emerging since its discovery.

As such, steel, brass, bronze, and so on are part of the subject alloy. Having that said, Steel is the alloy of carbon and iron, whereas titanium is an element in this chemistry world.

Key Takeaways

- Steel is a metal alloy made mostly of iron and carbon, while titanium is a pure metal element with a higher strength-to-weight ratio than steel.

- Steel is more abundant and less expensive than titanium, making it more commonly used in construction and manufacturing applications.

- Titanium is stronger and more corrosion-resistant than steel, making it more suitable for applications where weight and durability are critical, such as aerospace, medical, and military applications.

Steel vs Titanium

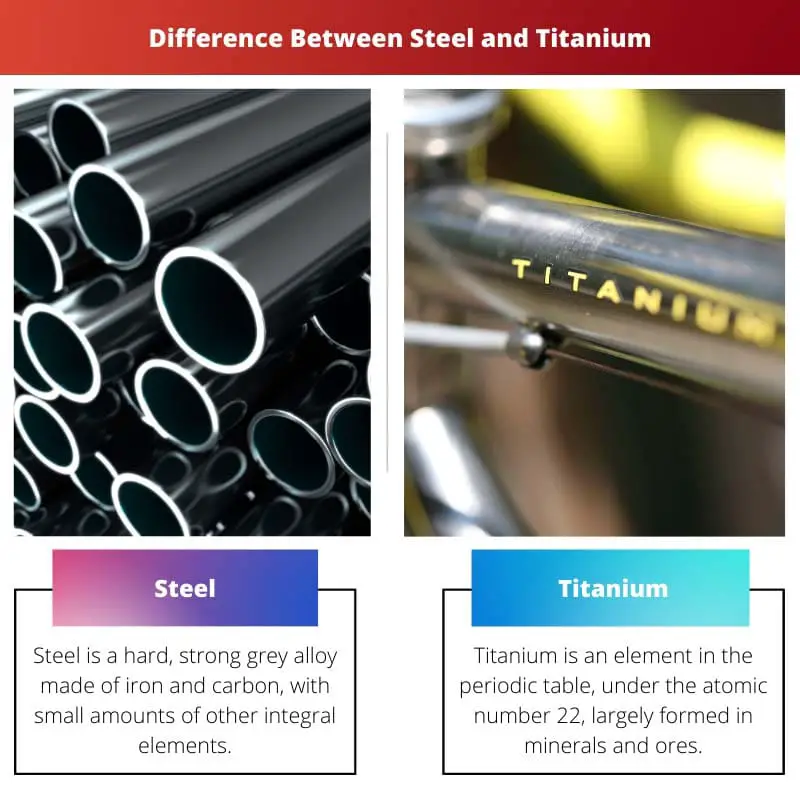

Steel is a metal made of iron and carbon. It is not costly. It is used in the construction of buildings. Steel is of four types. Titanium is an alloy which has low density. Its atomic weight is 47.867 u. Titanium is of four types. It can be used in the making of jewellery. It can also be used in the manufacturing of gadgets.

Steel is an alloy of iron and carbon with high tensile strength making it one of the crucial elements to construct a building strongly. Blast Furnace and Electric Arc Furnace prepare steel.

It is widely appreciated for its strength, ductility, toughness, durability, and other properties. Looking around every tall building, we can see the application of steel in it starting from near and far.

Besides, Titanium is a chemical element. Like oxygen, Nitrogen, Hydrogen, and Titanium are also in the same category. It is distinguished by its atomic number, 22.

Comparably, it is a silver-coloured element. Besides, it is light-weighted but also has high strength. They are found in various minerals and intermittent igneous rocks.

Comparison Table

| Parameters of Comparison | Steel | Titanium |

|---|---|---|

| Meaning | Steel is a hard, strong grey alloy made of iron and carbon, with small amounts of other integral elements such as manganese, silicon, phosphorus, Sulphur copper, oxygen, etc. It is in a Bluish-grey alloy of iron. | Titanium is an element in the periodic table, under the atomic number 22, largely formed in minerals and ores. Titanium is a silver alloy with low density and high strength. |

| Element | The main element of steel is Iron, and auxiliary to that- Manganese, nickel, Silicon, Sulphur, Titanium, Cobalt, Chromium, Niobium, Nitrogen, Copper, Oxygen, and Phorspohous are added. | Titanium is the sole element in the periodic table under the atomic number 22, with the symbol Ti (Titanium). It is measured that the atomic weight of Titanium is 47.867 u. |

| Types | There are four types of steel- Carbon Steel, Alloy Steel, Tool Steel, and Stainless Steel. | There are four types in Titanium- Ti 6AL-4v, Ti 6AL-4V ELI, Ti 3AL 2.5 and Ti 5AL-2.5 Sn. |

| Made Of | Steel is made out of Iron and Carbon as its underscore ingredient and contains 2 percent Carbon, 1 percent of manganese, and small amounts of other auxiliary elements. | Titanium is made of ores and minerals on the earth, which subsumes- Leucoxene, Ilmenite, and Rutile. |

| Used in | Steel plays a vital role in fabricating large-scale investment such as producing industrial goods, vehicles, machinery, and household appliances. | Titanium is largely used in manufacturing jewelry, rackets, bicycles, watches, and other gadgets. |

What is Steel?

Considering the previous point, Steel is an alloy of ninety-eight to ninety-nine per cent of Iron, like the element carbon contributes the remaining insignificant part.

Furthermore, the stell can be produced in two ways Blast and Electric Arc Furnaces. A blast furnace is made up of bricks with a height of 100 feet. The hearth is where the charge is put in.

Heated air, about 1000 kelvin, was introduced as a blast from the bottom of the furnace. Smelting occurs when the air from the bottom and charge from the heart cusps.

On the other hand, the Electric Arc Furnace generates heat between the arcs formed between the carbon electrode and other metal electrodes. In addition to that, the surface is made of steel with refractory bricks.

There are various alloys or Steel depending on their composition, such as mild steel, stainless steel, tungsten steel, manganese steel, Invar, etc.

Coming to their astounding features, steel can be easily stretched, making it good at ductility properties. They are good conductors of heat, malleable, durable, and strong tensile strength.

What is Titanium?

However, Titanium is a unique element belonging to d-block elements from group and period four. They are initially found as black sand with a bit of information that it is a combination of oxides of iron with some other element.

On the whole, it was mostly found in ore and minerals of Iron. The production of Titanium is done by reducing Titanium Chloride IV with magnesium, also by the Van Arkel process, where impure titanium is heated with iodine to convert into volatile iodine.

This iodine vapour is passed over a tungsten filament.

Following that, the pure titanium is dropped by the Iodine at the filament. Also, it is found in igneous rock like gabbro, norite, and anorthosite and from minerals such as ilmenite, anatase, brookite, leucoxene, perovskite, rutile, and sphene.

The element Titanium’s properties include high strength, light-weighted, and high corrosion resistance. For this reason, they are widely used as a material for the manufacture of air crafts.

Main Differences Between Steel and Titanium

- Steel is made up of iron and carbon elements, whereas Titanium is an element in the periodic table under the atomic number 22.

- Steel is made up of iron, carbon, and additional elements such as manganese, silicon, sulphur, phosphorus, etc. On the other hand, Titanium is largely made up of minerals and ores on the earth.

- Steel is used in constructing industrial goods, whereas Titanium is used to manufacture everyday products such as gadgets, bicycles and jewellery.

- Steel has four types- Carbon Steel is carbon-content, Alloy Steel made up of different elements like manganese, molybdenum and boron etc., Tool Steel is a combo of carbon and alloy steel, and Stainless Steel is an alloy of iron and chromium. Furthermore, Titanium is distinct into four types- Ti 6AL-4v, Ti 6AL-4V ELI, Ti 3AL 2.5 and Ti 5AL-2.5 Sn.

- Steel has a melting point of 1425 to 1540 Celsius, whereas the Titanium melting point of 1668 Celsius.

- https://www.jstor.org/stable/2097858

- https://books.google.co.in/books?hl=en&lr=&id=x3rToHWOcD8C&oi=fnd&pg=PP23&dq=meaning+of+titanium&ots=x7v-TDfqlX&sig=4wnpBy8fKJlU15RO6v1a5pK8s4Q

Steel is a versatile material that is widely used in various applications. It’s an important building material due to its strength and durability. To add to this, the production methods of steel have evolved significantly, making it more efficient and sustainable. Titanium’s unique properties make it an essential material in special applications such as aerospace and medical equipment.

You’ve highlighted the significance of steel and titanium in our industrial world very effectively. It’s important to consider the structural properties and cost-effectiveness of these materials for different applications. the use of steel and titanium show how material science has advanced to meet the complex demands of modern engineering.

I agree with your point. The advanced production processes have made steel an indispensable material in various industries. It is also important to note that the combination of steel and titanium in certain applications can provide unique benefits that cater to specific needs.

The comparison table effectively summarizes the fundamental differences between steel and titanium, including their elemental compositions, types, and specific uses. This analytical approach enhances our understanding of the distinct properties and applications of these materials.

The systematic evaluation of steel and titanium parameters highlights their unique characteristics and utility across different domains. It reinforces the significance of material science in enabling advanced engineering solutions and fostering sustainable technological development.

The comparison between steel and titanium provides insights into the unique characteristics of these materials. The different types of steel and titanium and their respective applications showcase the diverse utility of these elements in various industries.

The detailed exploration of steel and titanium allows us to understand the fundamental differences and specific use cases for each material. It’s fascinating to observe how these materials have shaped modern engineering and continue to drive innovation across different sectors.

The detailed description of steel production methods, including blast and electric arc furnaces, elucidates the intricate processes involved in manufacturing this essential material. Additionally, the properties and applications of titanium underscore its critical role in specialized industries.

The comprehensive overview of steel production and the geological origin of titanium provides a well-rounded perspective on these materials’ significance in engineering. The application of steel and titanium in different sectors showcases the breadth of their impact on modern technology.

The comprehensive overview of steel’s elemental composition, production methods, and unique types enhances our understanding of its diverse applications. Additionally, the detailed exploration of titanium’s origins and its role in the specialized manufacturing of various gadgets underscores its pivotal significance in modern engineering.

The detailed comparison between steel and titanium surfaces the nuanced distinctions between their elemental compositions, manufacturing processes, and underlying material properties. It highlights the pivotal role of these materials in driving technological advancements across different industry sectors.

The detailed elucidation of steel’s production methods and the distinctive properties of titanium enriches our knowledge of materials engineering. The comprehensive comparison between steel and titanium underscores their influential roles in shaping the landscape of modern technology and innovation.

The thorough evaluation of steel and titanium’s elemental composition and utility across diverse applications elucidates the multifaceted contributions of these materials to the dynamic field of materials science. This in-depth analysis enhances our appreciation of the advanced engineering solutions enabled by steel and titanium.

The comparative analysis of steel and titanium offers valuable insights into the specialized applications, unique properties, and structural significance of these materials. The continual evolution of steel production and the enduring role of titanium in advanced technologies signal the enduring impact of materials engineering on contemporary innovation.

The detailed description of steel, including its production methods, alloy compositions, and diverse types, provides a comprehensive understanding of its versatility. Titanium’s unique characteristics and applications highlight the significance of advanced materials in modern society.

The critical role of steel in construction and manufacturing, alongside the specialized use of titanium in aerospace and medical applications, underscores the interconnectedness of engineering disciplines. The synergy between these materials drives innovation and shapes the future of various sectors.

The evolution of steel production methods and the emergence of specialized titanium applications demonstrate the continuous development of materials engineering. These advancements play a pivotal role in enhancing key industries and enabling technological progress.

The in-depth analysis of steel and titanium emphasizes the importance of material selection in diverse sectors such as construction, aerospace, and manufacturing. The distinguishing properties of these materials contribute to their specialized applications and contribute to technological advancements.

The comparison between steel and titanium underlines the significance of material science in addressing the complex challenges of various industries. The complementary nature of these materials offers a wide spectrum of capabilities that cater to specific requirements.

Absolutely, the applications of steel and titanium reflect the integration of scientific knowledge and engineering expertise. This holistic approach to material selection has enabled the development of innovative solutions with enhanced performance and reliability.

The detailed explanation of steel’s production methods, such as blast and electric arc furnaces, coupled with the geological sources of titanium, broadens our comprehension of these materials’ origins and manufacturing processes. The unique applications of steel and titanium showcase the breadth of their influence in contemporary technology.

The comparison table provides a succinct summary of the essential attributes and applications of steel and titanium, signaling the integral role of material selection in driving engineering innovation. This comprehensive analysis contributes to our understanding of these materials’ multifaceted contributions to modern technology.

The emphasis on the distinct uses of steel and titanium underscores the diversity of engineering applications in which these materials play a critical role. The integration of advanced materials into various sectors reflects the dynamic nature of technological progress.

The exploration of various steel alloys and their unique properties, such as ductility, conductivity, and tensile strength, illuminates the diverse applications of this material. Moreover, the distinct characteristics of titanium and its elemental composition emphasize its specialized role in technological advancements.

The discussion on steel and titanium alloys deepens our understanding of their structural and functional capabilities in different industrial sectors. The comparative analysis enriches our knowledge of these materials’ contributions to engineering and innovation.