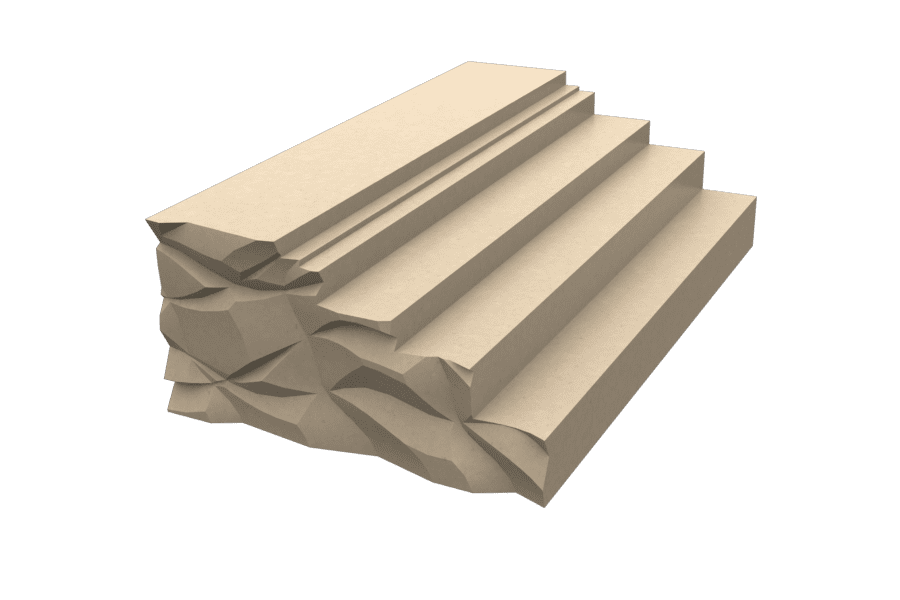

Crystal Face and Cleavage Plane are surfacing that are found on top of a Crystal. Both are the outermost areas of a crystal or metal. Crystal Face is the external part of the metal or crystal. It is defined by the crystallographic axes. The cleavage plane is the area where the metal or crystal tends to tear apart.

Key Takeaways

- Crystal faces represent a crystal’s naturally formed external surfaces, defined by its atomic arrangement.

- Cleavage planes occur when crystals break along certain internal planes due to weaker atomic bonds.

- Both characteristics help identify and classify minerals. Crystal faces reflect the inherent structure, while cleavage planes reveal fracture patterns.

Crystal Face vs Cleavage Plane

The difference between Crystal Face and Cleavage Plane is that Crystal Face is a surface over the metal or crystal, whereas Cleavage Plane is the plane that cuts or tears the crystal apart. Crystal Face is the connecting surface between two or more crystals.

Crystal Face is the outward plane surface that reflects the inside view. They are indicated by a series of numbers. There are various types of crystal faces, such as basal end faces and prism side faces which have separate series of numbers.

Crystal Faces have atoms tied together tightly. Cleavage is a cut or crack then happens on the crystallographic plane, also known as a Cleavage Plane. It is a fracture that makes the crystal split apart. As the split occurs, the atoms become weak bonded and so the Cleavage Plane appears to be smooth and shiny.

Comparison Table

| Parameters of Comparison | Crystal Face | Cleavage Plane |

|---|---|---|

| Definition | Crystal Faces are formed naturally over the surface of a metal or crystal. They reflect the internal structures of the crystals. | A cleavage plane is formed on the surface of the crystal due to cleavage or fracture. They are parallel to the crystal surface. |

| Texture | Crystal faces are smooth and shiny. | Cleavage Planes are smooth and shiny which depends on the crystal or metal. |

| Atoms Bond | Crystal Faces have atoms bonded tightly. | Cleavage Planes have atoms bonded loosely. |

| Halo Ray Path | Crystal Face numbers explain Halo Ray Paths in a precise manner. | Cleavage Planes explains Halo Ray Path in a detailed manner. |

| Uses | Crystal Face is used in determining the type of crystal or metal. | Cleavage Plans are used in identifying the type of mineral and its properties. |

What is Crystal Face?

Crystal Face is a smooth plane that is formed on the surface of the crystal or metal. They form the reflecting part of the crystal or metal. They reflect the internal structure and form of the crystal. The number of Crystal Faces depends on the type of crystal and metal.

New crystals are formed on the surface of the crystal faces. Crystal Faces are determined by a series of numbers. Each Crystal has their properties and characteristics, which determine the number of crystal faces.

Crystal Face helps in explaining precisely the halo ray path formation and penetration. Crystal Faces are determined using crystallographic axes. Crystal Faces are smooth and shiny. Crystal Face has a strong bond between its atoms. Two or more crystal faces combine to form a crystal form.

The Crystal Face of one crystal form intersects with another crystal face of a crystal form resulting in a new shape and pattern of a crystal or metal. There are two types of crystal forms resulting from the interaction between their Crystal Faces.

Three and their multiple faces are seen in the hexagonal system, whereas four and their multiple faces are seen in the orthogonal system, and eight and their multiple faces are seen in the tetragonal system.

What is Cleavage Plane?

Cleavage Planes are formed as a result of cracks or fractures on the surface of the crystallographic surface or plane. It is a tendency to form a crack or breakage on the crystal and split them into separate crystals.

Cleavage Planes are highly used in the mineral industry to identify metals and crystals. Cleavage Planes lead to corrosion and failure when the small crack that occurred grows beyond the grains present in between the Crystal Forms.

Cleavage Planes are occurred due to low-pressure breakage on the surface of the planes. It occurs in steel and iron with low pressure applied over it. Cleavage Planes are occurred due to many reasons.

They are due to dislocations and imperfections that eventually lead to corrosion and failure of the crystal or metal. There are different types of cleavage planes that occur and result in crystals.

These cracks and fractures penetrate, and it helps in identifying the types of crystals and their characteristics. Cleavage Planes are very smooth and shiny, like Crystal Face. They have a loose bond between the atoms, which is due to the fracture that makes the bonds loose or weakened.

Cleavage Planes are seen or observed parallel to Crystal Faces. It helps in cutting crystals and gems. It is used in electronic and mineral industries.

Main Differences Between Crystal Face and Cleavage Plane

- Crystal Faces can be found on the surface of the crystal, and they are indicated in terms of numbers, whereas Cleavage Planes are formed due to breakage or crack over the surface of the crystal.

- Crystal Faces are indicated in numbers, and their types are determined by the number of Crystal Faces present, whereas Cleavage Planes are determined by the crack that occurred on the surface.

- Crystal Face has strong bonds between the atoms, whereas Cleavage Planes have weak bonds between the atoms.

- Crystal Faces are used in determining the types of patterns present within the crystals, whereas Cleavage Planes are used in identifying the types of crystals and their properties.

- Crystal Faces help in precisely explaining the Halo Ray Path, whereas Cleavage Planes are used in explaining the Halo Path in detail.

- https://iopscience.iop.org/article/10.1088/0022-3735/5/10/012/meta

- https://journals.aps.org/prl/abstract/10.1103/PhysRevLett.86.5070

The article’s discussion of crystal faces and cleavage planes is both thorough and well-articulated.

This article provides a very comprehensive explanation of crystal faces and cleavage planes. The difference between the two is clearly presented.

I found the comparisons between crystal faces and cleavage planes to be particularly insightful.

I agree, the article is very informative and well-researched.

This article offers a comprehensive understanding of crystal faces and cleavage planes, highlighting their significance in mineral classification and analysis.

The article effectively differentiates between crystal faces and cleavage planes, shedding light on their respective characteristics and applications.

I found the section on the uses of crystal faces and cleavage planes to be particularly intriguing.

This article provides a comprehensive and detailed understanding of crystal faces and cleavage planes, making it a valuable resource for mineral enthusiasts.

This article provides a well-rounded explanation of crystal faces and cleavage planes, touching on their properties, uses, and formation.

The detailed descriptions of crystal faces and cleavage planes are helpful in understanding the characteristics of different minerals.

The comparison table presented in the article makes it easier to grasp the distinctions between crystal faces and cleavage planes.

I agree, the table is a great visual aid for understanding the differences.

The detailed information about crystal faces and cleavage planes is quite enlightening.

The detailed comparison between crystal faces and cleavage planes is quite informative and educational.

The detailed descriptions of crystal faces and cleavage planes provide valuable insights into mineral identification and properties.