Welding is a process in which parts are joined together by heating the object’s surface to the melting point.

Industrial professionals employ various welding techniques to create the required assemblies depending on the product specifications and the part.

Depending on the creation of workpieces, arc welding processes are also very. So, choosing the right one for the project’s success is necessary.

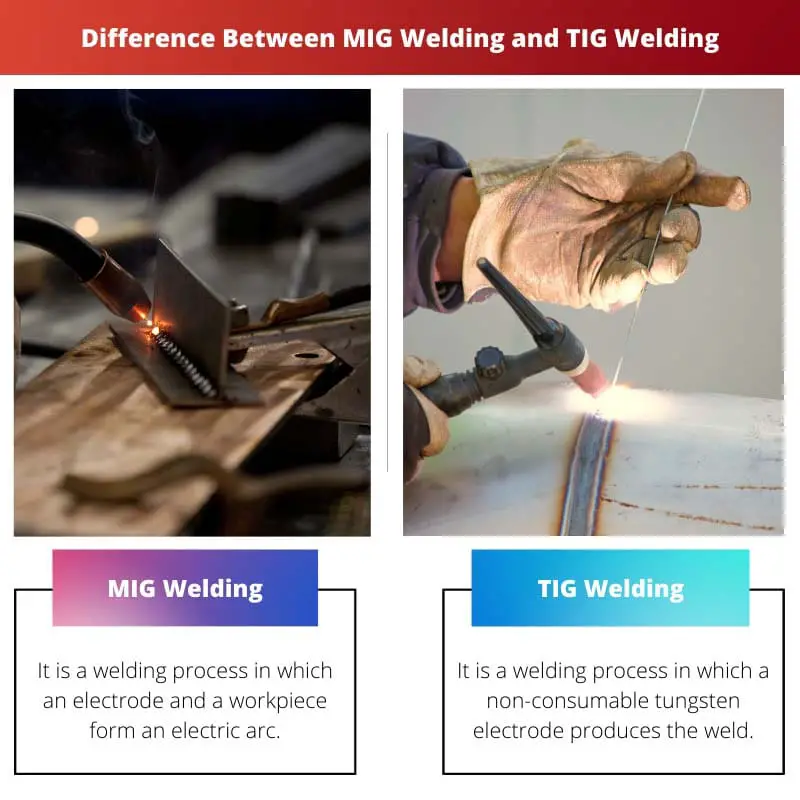

Both the MIG and TIG welding form the weld with the help of an electric arc. Both techniques are different from each other, and choosing the wrong one can create more headaches.

Key Takeaways

- Metal Inert Gas (MIG) welding feeds a continuous wire electrode, while Tungsten Inert Gas (TIG) welding uses a non-consumable tungsten electrode.

- MIG welding is faster and easier to learn, whereas TIG welding offers greater precision and control.

- MIG welding works well on various metals, but TIG welding is better for thinner materials and more delicate work.

MIG Welding vs TIG Welding

Mental Inert Gas (MIG) welding is the process in which electric arcs are created by heating an electrode and a workpiece metal. A shieling gas like Nitrogen is passed through the welding gun to protect the wire from contamination. Tungsten Inert Gas (TIG) welding is the process which uses a Tungsten electrode to produce welds. It is used in multiple industries like aerospace and auto-repair.

MIG or Metal inert gas or GMAW (Gas metal arc welding), or MAG (Metal active gas). Humphry Davy invented MIG welding in 1949.

MIG welding is a process of forming an electric arc between an electrode and a workpiece. With the help of an inert shield (nitrogen), the welded area is safeguarded from atmospheric contamination.

TIG or tungsten inert gas or GTAW. Rusell Meredith invented TIG welding in 1942. It is a process of arc welding in which non-consumable tungsten electrodes are used to produce the weld.

Inert shielding gas such as argon protects the welded area from atmospheric contamination.

Comparison Table

| Parameters of Comparison | MIG Welding | TIG Welding |

|---|---|---|

| Interpretation | It is a welding process in which an electrode and a workpiece form an electric arc. | It is a welding process in which a non-consumable tungsten electrode produces the weld. |

| Invented | In 1949 | In 1942 |

| Inventor | Humphry Davy’s | Russell Meredith |

| Malleability | Harder | Softer |

| Deposition rate | Higher | Lower |

What is MIG Welding?

MIG is an acronym for metal inert gas welding. It is a process in which weld is produced with the help of an electrode and a workpiece.

An electric arc is formed between both the components, like wire and metal, and is heated until its melting point. While doing this process, with the help of a welding gun, a shielding gas is fed to protect the wire from atmospheric contaminants.

MIG welding relies on the shielding gas flow, so it is practised inside to avoid getting disturbed by the wind.

If the welding process is performed in the field, the erection of tents or plastic shields is required. From lawn art to the production of automobiles, it is used in everything.

For industries, MIG building has become a staple for several reasons. The process of welding can either be semi-automated or fully automated.

An arc generator is used in semi-automated, whereas robotic arms are used instead of human welders in fully automated. As a result, MIG welding is used in many fields.

MIG welding is relatively easy to learn, so training in MIG welding can be completed in a short amount of time. This kind of welding is also fast in process and requires almost no cleanup.

MIG Welding is used in automobile assembly, construction, railroads, pipe signal fabrications, and other areas.

What is TIG Welding?

In TIG welding, an arc is made by a welder between the metal and the electrode of non-consumable tungsten. A molten weld pool is formed when the arc hits the base metal.

A filler metal’s thin wire is hand-fed slowly into the weld pool. All the while, inert shielding gas is fed to protect it from atmospheric contamination.

As compared to other types of processes, TIG welding is used for more metals. That’s why several industries rely on this kind of welding.

TIG welding is used in the aerospace industry to construct aeroplanes and spacecraft. It is also used in repair shops for auto body and sculpture welding.

In TIG welding, a welder can precisely control amperage and heat using a thumb or foot remote control switch.

TIG welder is easy to control vet excellent dexterity over the process due to a thin welder. That’s why the TIG building is preferred for projects requiring detailed curves or designs.

This welding process works well on thin metal or pieces due to the low amperage usage by torch.

With the remote-control switch and low amperage, it is easy for a welder to quickly switch from thin pieces to thick ones. The world produced by TIG is clean and slag-free.

Main Differences Between MIG Welding and TIG Welding

- In terms of suitability, MIG welding is suitable for homogeneous welding. On the flip side, TIG welding is suitable for autogenous mode.

- When it comes to the usage of gases, MIG welding uses nitrogen, oxygen, and helium end mixture of three of them. Only argon gas is used in TIG welding.

- The process of MIG welding is faster than TIG welding. On the other hand, the TIG welding process is slow compared to other processes.

- MIG welding is carried out in DCEP or AC polarity for the increase in filler deposition rate. In contrast, TIG welding is carried out in DCEN or AC polarity to increase electrode life.

- The electrode-cum filler in MIG welding comes in the form of a very long wire wound in a pool with a small diameter. But the TIG welding filler comes in the form of a short length rod with a small diameter.

- https://www.sciencedirect.com/science/article/pii/S0924013699004355

- https://books.google.com/books?hl=en&lr=&id=mr5QAwAAQBAJ&oi=fnd&pg=PP1&dq=mig+welding&ots=-G2_8pA8fk&sig=0eup5ccANH9CdHw1fryWXBGE6zg

Last Updated : 11 June, 2023

Piyush Yadav has spent the past 25 years working as a physicist in the local community. He is a physicist passionate about making science more accessible to our readers. He holds a BSc in Natural Sciences and Post Graduate Diploma in Environmental Science. You can read more about him on his bio page.

The article provides a wealth of technical information on MIG and TIG welding, making it a must-read for anyone looking to deepen their understanding of welding processes.

The comparison of the malleability and deposition rates between MIG and TIG welding is particularly illuminating, shedding light on the technical aspects of these processes.

Absolutely, the detailed technical comparisons in the article are invaluable for professionals seeking to understand the nuanced differences between MIG and TIG welding.

This article provides a comprehensive comparison between MIG and TIG welding, making it easier for professionals to choose the right technique for their projects.

Absolutely, the detailed breakdown of the differences and applications of each welding method is very informative and useful for anyone in the industry.

The article does an excellent job of explaining the advantages and applications of MIG and TIG welding in various industries, providing valuable insights for professionals.

I agree, the article successfully highlights the practical implications of choosing the right welding technique for different projects, making it an essential read for industry professionals.

I appreciate how this article highlights the precision and control offered by TIG welding, making it ideal for delicate work and thinner materials.

Yes, the in-depth explanation of the advantages and applications of TIG welding is very enlightening and helps professionals make informed decisions in their work.

The comparison table provided in the article really simplifies the differences between MIG and TIG welding, making it easy to understand for those new to the industry.

I couldn’t agree more. The comparison table is a great visual aid to grasp the distinctions between the two types of welding.

This article provides a clear and concise breakdown of the main differences between MIG and TIG welding, making it a valuable resource for professionals and enthusiasts alike.

Absolutely, the author has done a great job of presenting complex technical information in an accessible and understandable way.

I found the detailed explanations of MIG and TIG welding processes to be very helpful. The article covers all the essential aspects of these techniques.