Polyurethane and varnish are both wood finishes, but they differ in composition and performance. Polyurethane is a synthetic polymer coating, offering enhanced durability and water resistance, making it suitable for high-traffic areas. Varnish, a traditional blend of resins and oils, provides a more natural appearance but may require more coats for comparable protection.

Key Takeaways

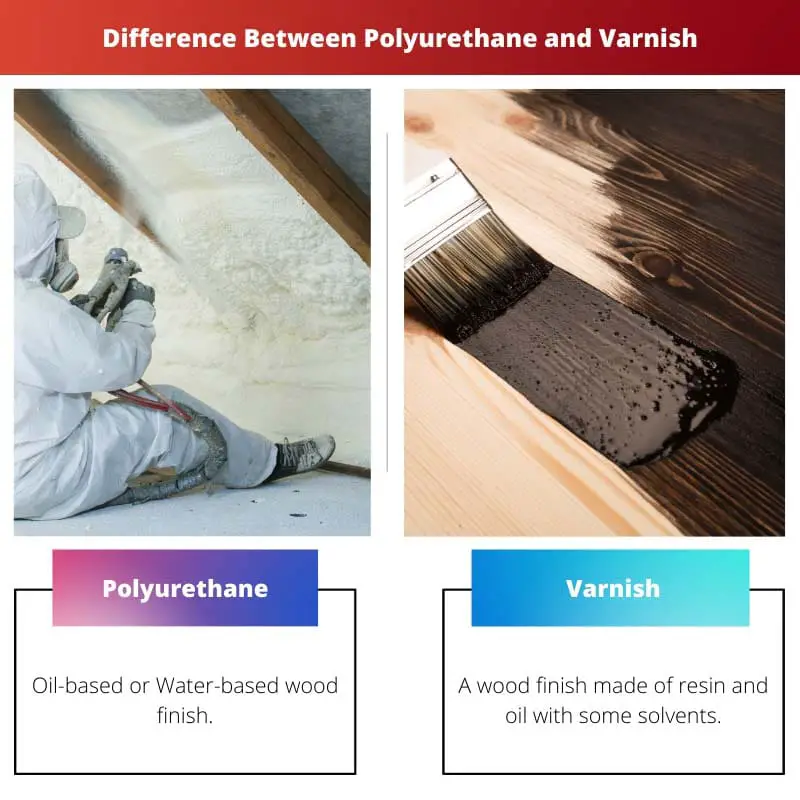

- Polyurethane is a synthetic resin that provides a protective coat to surfaces, while the varnish is a clear or transparent coating made from resins, oils, and solvents.

- Polyurethane is more durable and resistant to heat and chemicals than varnish, which can easily scratch and wear off over time.

- Varnish enhances the natural beauty of the wood and provides a glossy finish, while polyurethane provides a clear finish and can be used on various surfaces.

Polyurethane vs Varnish

Polyurethane is an oil or water-based wood finishing. It is highly durable. It gives a shiny look to the wood. It must not be applied to outdoor things. It is best suited for indoor things. Varnish is wood finishing made with oil and resin. Some solvents are also added to varnish. It is UV resistant and best suited for outdoor things.

Polyurethane is a wood finish that makes the hardwood surface shinier. It is available oil-based and water-based. The oil-based is more durable, and the protection margin is higher.

Varnish is a combination of resin and oil with some solvent. It is resistant to UV. It is very much used for outdoor wood finish. It is done on garden benches or decks.

Comparison Table

| Feature | Polyurethane | Varnish |

|---|---|---|

| Durability | More durable, especially against scratches and chemicals | Less durable, more prone to scratches and water damage |

| Flexibility | Less flexible, may crack on surfaces that expand and contract | More flexible, better for surfaces that move slightly |

| Drying Time | Dries faster, especially water-based varieties | Dries slower |

| Coats Needed | Fewer coats due to thicker consistency | More coats for full protection |

| Finish | Can be clear, satin, or glossy | Typically clear, enhances natural wood grain |

| Application | Better for indoor furniture, cabinets, floors | Better for outdoor furniture, decks, and trim |

| Cleanup | Easier cleanup with water-based options | Requires mineral spirits or paint thinner for cleanup (oil-based) |

| Cost | Slightly more expensive | Generally less expensive |

What is Polyurethane?

Polyurethane is a versatile and widely used polymer that finds applications in various industries due to its exceptional properties. It is a type of polymer composed of organic units linked by urethane links. Polyurethanes are known for their durability, flexibility, and resistance to abrasion, making them suitable for a diverse range of applications.

Molecular Structure and Composition

Polyurethanes are formed through the reaction of polyols (compounds with multiple hydroxyl groups) with diisocyanates. The combination of these two components results in the formation of urethane linkages, which constitute the backbone of the polymer. The specific choice of polyols and diisocyanates determines the physical and chemical properties of the polyurethane.

Types of Polyurethane

1. Flexible Polyurethane Foam

Flexible polyurethane foams are commonly used in cushioning and padding applications. They provide comfort and resilience, making them ideal for mattresses, upholstery, and automotive seating.

2. Rigid Polyurethane Foam

Rigid polyurethane foams are employed for insulation purposes in construction and refrigeration. They exhibit excellent thermal insulation properties, making them energy-efficient materials.

3. Thermoplastic Polyurethane (TPU)

TPU is a versatile type of polyurethane that combines the characteristics of rubber and plastic. It is often used in the production of flexible and durable products such as hoses, tubing, and athletic footwear.

4. Polyurethane Elastomers

Polyurethane elastomers are known for their elasticity and abrasion resistance. They are utilized in the manufacturing of seals, gaskets, and wheels for material handling equipment.

Properties of Polyurethane

1. Durability

Polyurethanes are renowned for their high durability, making them suitable for applications that require long-lasting materials. This property contributes to the longevity of products in various industries.

2. Flexibility

The flexibility of polyurethanes allows for the production of materials that can bend and stretch without losing their structural integrity. This feature is particularly valuable in applications where flexibility is essential, such as in elastomers and foams.

3. Chemical Resistance

Polyurethanes exhibit resistance to various chemicals, enhancing their suitability for applications where exposure to corrosive substances is a concern. This property expands their utility in diverse industries, including manufacturing and automotive.

4. Thermal Insulation

Rigid polyurethane foams have excellent thermal insulation properties, making them widely used in the construction industry for insulation purposes. This contributes to energy efficiency by minimizing heat transfer.

Applications of Polyurethane

1. Construction

Polyurethanes are extensively used in construction for insulation, sealants, and adhesives. Rigid foams contribute to energy-efficient buildings, while sealants and adhesives provide robust bonding solutions.

2. Automotive

In the automotive industry, polyurethanes are employed in various components, including seating, interior trim, and insulation. Their lightweight and durable nature make them ideal for enhancing fuel efficiency.

3. Footwear

Flexible and thermoplastic polyurethanes are commonly used in the production of footwear. These materials provide comfort, flexibility, and durability, meeting the demands of the footwear industry.

4. Medical Devices

Polyurethane elastomers are used in the manufacturing of medical devices, such as catheters and tubing, due to their biocompatibility and flexibility.

Environmental Considerations

While polyurethanes offer numerous benefits, there are environmental concerns associated with their production and disposal. Efforts are underway to develop more sustainable forms of polyurethane and to promote recycling to mitigate their environmental impact.

What is Varnish?

Varnish is a versatile and protective coating applied to various surfaces, primarily composed of resin and oil. It serves a multitude of purposes, ranging from enhancing the aesthetic appeal of wooden surfaces to providing a protective layer for paintings and metals. In this discussion, we’ll delve into the composition, application, and benefits of varnish.

Composition of Varnish

Resin

The primary component of varnish is resin, which is derived from natural sources like trees or synthesized from petrochemicals. Common natural resins include dammar, rosin, and shellac, while synthetic resins like alkyd and polyurethane are also widely used. Resin provides varnish with its protective and adhesive properties.

Oil

Oil acts as a carrier for the resin, facilitating its application and ensuring an even spread across the surface. Linseed oil, tung oil, and other drying oils are commonly used in varnish formulations. The choice of oil influences the drying time, durability, and appearance of the final varnish.

Types of Varnish

Oil-Based Varnish

Oil-based varnishes, with a combination of resin and drying oil, are known for their durability and rich finish. They are commonly used on wooden surfaces and paintings, providing protection against moisture and wear.

Water-Based Varnish

Water-based varnishes use water as a carrier instead of traditional oils, making them environmentally friendly. While they may dry faster, they may not offer the same depth of finish as oil-based varnishes.

Polyurethane Varnish

Polyurethane varnishes, a type of synthetic resin, provide a high level of protection and durability. They are resistant to chemicals, making them suitable for various applications, from wooden furniture to floors.

Application Process

Surface Preparation

Before applying varnish, proper surface preparation is crucial. This involves sanding the surface to ensure it is smooth and free of imperfections. Dust and debris should be removed to achieve an even finish.

Application Techniques

Varnish can be applied using brushes, rollers, or sprayers. Each method has its advantages, depending on the type of surface and the desired finish. Multiple thin coats are often recommended for better adhesion and a smoother appearance.

Benefits of Varnish

Protective Barrier

Varnish forms a protective barrier that shields surfaces from environmental factors such as moisture, UV rays, and abrasion. This protection helps prolong the life of wooden structures, paintings, and metal surfaces.

Aesthetic Enhancement

Varnish enhances the natural beauty of wood by accentuating its grain and color. For paintings, it provides a glossy or matte finish, enhancing the visual appeal and preserving the artwork for years.

Versatility

The versatility of varnish extends to its application on various materials, including wood, metal, and canvas. This adaptability makes varnish a widely used and effective protective coating in diverse industries.

Main Differences Between Polyurethane and Varnish

- Composition:

- Polyurethane: It is a type of plastic resin that forms a durable, protective coating when applied to surfaces. It is typically available in water-based or oil-based formulations.

- Varnish: Varnish is a clear, protective finish made from a combination of resins, oils, and solvents. It can be oil-based, water-based, or solvent-based.

- Application:

- Polyurethane: Can be applied as a clear finish on various surfaces, including wood, metal, and concrete. It is often used for furniture, floors, and outdoor applications.

- Varnish: Primarily used on wood surfaces to enhance their natural beauty. It is commonly used for furniture, wooden floors, and other interior woodwork.

- Drying Time:

- Polyurethane: Generally has a longer drying time compared to varnish. It can take several hours to a day or more to dry between coats.

- Varnish: Typically dries faster than polyurethane. The drying time varies based on the type of varnish and environmental conditions.

- Durability:

- Polyurethane: Known for its high durability and resistance to scratches, chemicals, and UV rays. It provides a strong protective layer against wear and tear.

- Varnish: Offers good durability, but it may not be as resistant to abrasion and chemicals as polyurethane. It is well-suited for indoor applications.

- Flexibility:

- Polyurethane: Tends to be more flexible than varnish, allowing it to better withstand movements and changes in temperature without cracking.

- Varnish: While durable, varnish may be more prone to cracking or chipping when exposed to extreme temperature changes or constant movement.

- Appearance:

- Polyurethane: Can have a slightly plastic-like appearance, especially with high-gloss finishes. It may alter the natural color of the wood.

- Varnish: Enhances the natural color and grain of the wood without adding a plastic-like sheen. It tends to provide a more traditional and warm finish.

- Maintenance:

- Polyurethane: Requires minimal maintenance, as it provides a strong protective layer. Cleaning is often easy, and it can withstand regular wear.

- Varnish: May require more frequent maintenance, as it may be more susceptible to scratches and wear over time.

- Environmental Impact:

- Polyurethane: Water-based polyurethane options are considered more environmentally friendly than oil-based ones, emitting fewer volatile organic compounds (VOCs).

- Varnish: Water-based varnishes are generally more environmentally friendly than oil-based varnishes, as they release fewer VOCs into the air.

- https://onlinelibrary.wiley.com/doi/abs/10.1002/app.22432

- https://link.springer.com/article/10.1007/s11998-016-9805-5

The comprehensive explanations of polyurethane and varnish offer valuable insights into the application and benefits of each type of wood finishing. It’s a must-read for anyone working with hardwood floors.

Understanding the main differences between polyurethane and varnish and their specific uses provides clarity on how to protect wood surfaces effectively for different applications.

Indeed, the article’s emphasis on the applications and properties of both wood finishes is valuable for making educated decisions when working with wood surfaces.

The practical explanation of polyurethane and varnish usage is beneficial for ensuring the longevity and visual appeal of wood finishes.

The information provided about polyurethane and varnish adds depth to the understanding of wood finishes and helps in making informed choices when finishing wooden elements for indoor or outdoor use.

Absolutely, the article’s coverage of the properties and differences between polyurethane and varnish is essential for those engaged in wood finishing projects.

The detailed description of polyurethane and varnish helps in understanding their characteristics and correct usage. It’s beneficial for anyone looking to preserve the quality of hardwood floors.

Absolutely, the article is a valuable resource for those seeking to enhance and protect hardwood floors with the right wood finish.

I agree, the article’s focus on explaining the differences and applications of polyurethane and varnish is excellent for those interested in home improvement.

The comparison table between polyurethane and varnish provides a quick overview of their differences. This is quite useful for selecting the right finishing for indoor and outdoor applications.

Certainly, the comparison table simplifies the decision-making process for applying wood finishes based on their specific properties and usage.

The article’s comprehensive breakdown of polyurethane and varnish properties and applications provides a solid foundation for working with wood finishes. It’s a valuable resource for anyone involved in home improvement projects.

Absolutely, the article’s detailed coverage of these wood finishes is essential for those looking to preserve the natural beauty of wood surfaces and enhance their durability.

I appreciate the detailed comparison between polyurethane and varnish. It’s helpful to understand the differences between the two and when it’s best to use each one on hardwood floors.

The comparison provided is indeed informative for homeowners and anyone planning to apply wood finishes.

The information provided about polyurethane and varnish is enlightening and serves as a guide for achieving the best results when refinishing wood surfaces. It’s beneficial for anyone in the woodworking industry.

Indeed, the article’s detailed comparison helps in understanding the characteristics and ideal uses of polyurethane and varnish, which is essential for professionals and enthusiasts in wood finishing.

The key takeaways from polyurethane to varnish are presented clearly. It’s good to have this information before deciding which type of wood finish to use.

Understanding the differences in durability, appearance, and usage of these wood finishes can help in making informed decisions when working with hardwood floors.

The in-depth information about polyurethane and varnish enables readers to make well-informed decisions for protecting and beautifying wood surfaces. This is vital for maintaining home aesthetics.

Absolutely, the article’s insights into these wood finishes are crucial for homeowners and professionals who care about the quality of their hardwood floors.