An air conditioner takes heat from your home’s air, sends it outside, and then recirculates the newly cooled air throughout your home. Your air conditioner’s compressor and condenser are two critical components.

Their functions and upkeep are required to keep them running.

Key Takeaways

- Compressors increase the pressure of a gas, while condensers transform gas into a liquid state.

- Compressors are found in various systems, such as refrigeration and air conditioning, while condensers are primarily used in heat exchange systems.

- Both components are essential for the proper functioning of a cooling system but perform different tasks.

Compressor vs Condenser

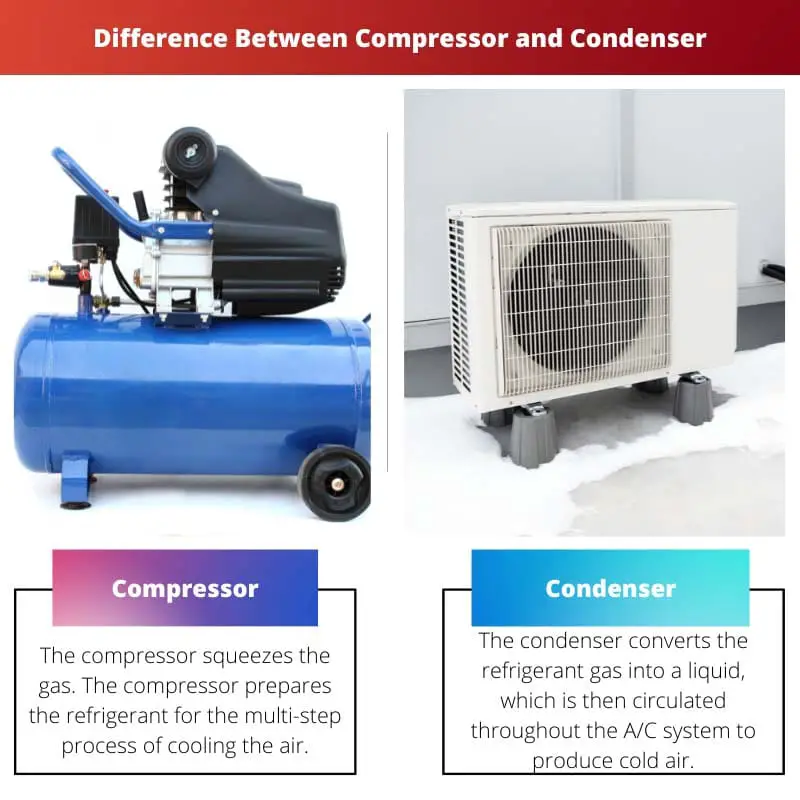

The difference between compressor and condenser is that a compressor reduces the volume of gas to add pressure to it. On the other hand, the condenser takes that pressurized gas in and turns it into a liquid-vapor. The compressor consists of components like a motor and pumps, whereas the condenser comprises a coil and fan.

The compressor squeezes the gas. The compressor prepares the refrigerant for the multi-step process of cooling the air.

Compressors are primarily used to raise the fluid’s potential energy, density, and pressure. By compressing the fluid, the pressure of the fluid is increased.

Air compressors are air compressors that compress air.

The condenser converts the refrigerant gas into a liquid, which is then circulated throughout the A/C system to produce cold air. The condenser is in charge of converting the compressed gas from the compressor into a liquid-vapor.

Condensers are used in many industrial systems to effectively reject heat.

Comparison Table

| Parameters of Comparison | Compressor | Condenser |

|---|---|---|

| Function | Reduces the volume of gas to add pressure | Takes in the pressurized gas turning it into a liquid-vapor |

| Types | Reciprocating, Rotary, Centrifugal, Screw and Scroll Compressor | Air-cooled, water-cooled, and evaporative condenser |

| Components | Electric motor, pump, and receiver | Main unit, coil, and fan |

| Order of Function | Works before the condenser | Works after the compressor |

| Location of Placement | Inside the main unit of the AC/fridge | Outside the building |

What is Compressor?

A compressor is a device that reduces the volume of a fluid in order to increase the pressure of that fluid. After compressing a fluid, a compressor can also store it.

Because gases are compressible, a compressor is stated to be used to pressurize and store them. Air is the most widely compressed gas, though any gas can be compressed.

The ability of compressors to compress gases is governed by thermodynamic rules. The compressibility component z is added to the ideal gas equation to account for variations in gas behavior, yielding:

PV = zNRT

Many hermetic and semi-hermetic compressors, which may have built-in oil pumps, can only work in a limited speed range or at a set speed, but electric motor-driven compressors can be modified using a VFD or power inverter.

Positive Displacement and Dynamic Compressors are the two types of compressors. Rotary and Reciprocating Compressors are two types of Positive Displacement Compressors.

Axial and centrifugal Dynamic Compressors are the two types of Dynamic Compressors.

A piston in a reciprocating compressor compresses the intake air, raising its pressure. The air displaces via the outlet valve when the pressure is high enough.

Centrifugal compressors rotate the gas, increasing its velocity, and then convert velocity energy to pressure energy via a divergent duct.

Rows of spinning and stationary blades make up an axial compressor. The velocity of gas passing between these blades is enhanced by increasing kinetic energy.

When the velocity is reduced, it results in an increase in pressure.

What is Condenser?

A condenser is a heat exchanger that chills a gaseous substance into a liquid state for use in heat transfer systems. As a result, the latent heat of the substance is liberated and redistributed to the surroundings.

A condenser is a chemical device that cools and condenses the hot vapor into a liquid. This is not to be confused with a condensation reaction, in which two fragments are added and removed to produce a single molecule.

A condenser is a piece of equipment as well as a raw material that is commonly employed in industries. It comes in a variety of shapes and sizes, including barometer condensers, surface condensers, indirect condensers, and so on.

A condenser is also utilized as a hot terminal in the refrigeration business. This terminal is frequently used to obtain heat, which is available in cold weather.

Condensers are widely utilized in the refrigeration industry and in automobiles. It is used to transform water vapors into liquids and functions as a heat exchanger.

A condenser lowers the temperature of water vapor utilizing any other liquid with a lower temperature in this process.

The temperature of the water vapor reduces as a result of establishing a thermodynamic contact. The superheated state of the liquid is treated by condensers, which cool it down.

Corrosion and rusting of the condensers are a regular occurrence.

However, the term condenser can be used to represent a variety of devices in other disciplines of research. From a mechanical standpoint, it can be described as a device that reduces the amount of heat present in a system to condense gas into a liquid.

Main Differences Between Compressor and Condenser

- The function of a compressor is to reduce the volume of gas, and the function of a condenser is to turn the gas into a liquid vapor.

- The types of compressor include Rotary, Screw and Scroll Compressor and the types of condenser include water-cooled and evaporative condenser

- The components of a compressor include a motor, pump, and receiver and the components of a condenser include the main unit, coil, and fan.

- The order of function of compressor and condenser is that the compressor works first, and the condenser performs after.

- Compressors are placed inside the main unit of the AC, and condensers are fitted outside the building.

References

- https://onlinelibrary.wiley.com/doi/abs/10.1002/er.936

- https://www.sciencedirect.com/science/article/pii/S0140700706000284